A chemical inventory program is much more than a glorified spreadsheet. It’s a living, breathing system that tracks every chemical in your facility, from the moment it arrives on the loading dock to the day it’s safely disposed of. Think of it as an air traffic control system for your chemicals, giving you a complete picture of what you have, where it is, and exactly how to handle it safely.

Decoding Your Chemical Management Strategy

At its heart, a chemical inventory program fundamentally changes how an organisation handles hazardous substances. It gets you away from static, often out-of-date lists and into a dynamic digital framework. The system is built to provide instant, accurate answers to critical questions for anyone working in an environmental, health, and safety (EHS) role, as well as those in procurement or operations.

This organised approach swaps chaotic, error-prone manual methods for automated, real-time data. The main goal is to centralise all your chemical information, making it easy to find and act on. Instead of frantically flipping through binders to find a Safety Data Sheet (SDS) during an emergency, a modern program puts that critical information just a few clicks away.

From Reactive Burden to Proactive Advantage

For too long, chemical management has been a reactive chore—updating lists when someone gets around to it and scrambling to get organised during an audit or an incident. A digital chemical inventory program completely flips that script, turning a compliance headache into a genuine strategic advantage. By automating the tracking and monitoring, it frees up your EHS professionals to focus on what really matters, like proactive risk reduction and meaningful safety training.

This forward-thinking stance is essential for staying on top of complex regulations. For instance, in Belgium, a robust chemical inventory program has been a cornerstone of compliance since the full implementation of the REACH regulation. A 2023 study by the European Chemicals Agency (ECHA) found that companies using digital inventory systems cut their non-compliance incidents by an impressive 62%, avoiding fines that average €45,000 per violation. These numbers speak for themselves, showing the direct financial and safety benefits of adopting a modern system. You can discover more insights about CERS compliance on Triumvirate.com.

A modern chemical inventory platform is the foundation of a safe workplace. It doesn't just list what you have; it provides the intelligence to manage those substances responsibly, protecting both your people and your bottom line.

The Evolution From Spreadsheets to Smart Systems

The move from manual tracking in spreadsheets to a dedicated software solution is a massive leap forward. Spreadsheets are familiar, sure, but they simply can’t handle the intricate demands of chemical safety and compliance. A purpose-built program offers a structured, secure, and vastly more powerful alternative.

The journey from manual spreadsheets to a modern chemical inventory program marks a significant upgrade in how businesses manage safety and compliance. While spreadsheets were once the go-to tool, their limitations become glaringly obvious when dealing with the complexities of hazardous substances.

Manual Spreadsheets vs Modern Chemical Inventory Program

| Aspect | Manual Spreadsheets | Modern Chemical Inventory Program (e.g., NextSDS) |

|---|---|---|

| Data Integrity | Prone to typos, formula errors, and version control chaos. Highly unreliable. | Validated inputs and standardised fields ensure data is accurate and consistent. |

| Accessibility | Often siloed on one person's computer, leading to outdated, conflicting copies. | Secure, role-based access for the entire team, ensuring everyone sees the same information. |

| Automation | Entirely manual. Updating SDSs and running reports is tedious and time-consuming. | Automates key tasks like SDS updates, regulatory screening, and report generation. |

| Compliance | Keeping up with regulatory lists is a manual, error-prone cross-checking exercise. | Automatically screens inventory against global regulatory lists, with real-time alerts. |

| Emergency Response | Finding critical hazard data in a crisis can be slow and difficult. | Instant access to SDSs, hazard info, and storage guidelines with a few clicks. |

Ultimately, a modern system like NextSDS isn't just a better spreadsheet; it's a completely different approach. It’s a proactive, intelligent tool designed to make the workplace safer and compliance easier to manage.

Essential Features of a Modern Chemical Management Platform

A good chemical inventory program isn’t just a digital filing cabinet; it’s a command centre for your entire chemical safety operation. It’s built on a foundation of smart, connected features that work together to automate the grunt work, deliver instant clarity, and keep your business safe and compliant. The aim is to move from a static list of chemicals to a dynamic, active safety partner.

This shift starts with how the system handles Safety Data Sheets (SDSs). Forget about manual data entry – a slow, tedious process that’s an open invitation for human error. A modern platform does the heavy lifting for you. It’s the difference between trying to transcribe a book by hand and having a clever assistant who reads it, understands the key points, and flags exactly what you need to know.

Automated SDS Management and Data Extraction

At the heart of any worthwhile chemical management platform is its ability to intelligently process SDSs. The best systems use AI to scan these documents and automatically pull out the critical information. We're not just talking about storing a PDF file; we’re talking about unlocking the valuable, actionable data held within it.

- Intelligent Data Parsing: The software identifies and catalogues essential details like CAS numbers, hazard classifications, and required personal protective equipment (PPE).

- Version Control: It automatically flags outdated SDSs and helps you find the latest versions from your suppliers, ensuring your safety information is always current.

- Centralised Library: All this extracted data flows into a single, searchable library, creating one reliable source of truth for everyone in your organisation.

This automated approach frees up countless hours of administrative time and makes your data dramatically more accurate. You can dive deeper into the benefits in our guide on chemical inventory management software.

Real-Time Regulatory Screening and Alerts

Keeping up with the constantly shifting world of chemical regulations can feel like a full-time job. A modern platform acts as your vigilant watchdog, continuously screening your chemical inventory against a huge database of global and regional regulatory lists. For any business that handles controlled or hazardous substances, this is a non-negotiable feature.

When you add a new chemical or a regulation gets an update, the system instantly cross-references your inventory. If it finds a match—for instance, a substance you use is newly listed as a Substance of Very High Concern (SVHC) under REACH—it sends an immediate alert to your EHS team. This gives you the head start you need to take corrective action long before an inspector shows up at your door.

A proactive alert from your chemical inventory program is the digital equivalent of a tap on the shoulder from a compliance expert, warning you of a potential issue before it becomes a problem.

Integrated Safety and Storage Tools

A truly powerful system goes beyond data management and provides practical, on-the-floor safety tools. It translates complex chemical data into simple, actionable guidance that your team can use every single day.

This is where the platform’s intelligence really proves its worth by helping to prevent dangerous situations from ever happening. For example, smart storage management tools use chemical compatibility rules to stop hazardous reactions. The software can flag when you’re storing incompatible chemicals, like flammables and oxidisers, too close together, helping you maintain the safe separation distances required by law.

This kind of functionality has a measurable impact. A 2022 review of the Belgian chemical sector found that effective inventory programs helped cut regulatory violations by 48% since 2018. The same data showed that mobile QR code access—another critical feature—slashed emergency response times in drills by 37%. You can learn more about the findings from Belgian chemical sector reviews on vertere.com.

Other essential integrated tools include:

- On-Demand GHS Label Generation: Instantly print compliant labels for secondary containers, making sure every pictogram, signal word, and hazard statement is correct.

- Risk Assessment Modules: Move beyond basic hazard identification with tools that help you evaluate the real-world risk of exposure in your specific workplace scenarios.

- Mobile Access with QR Codes: Stick QR codes on containers or storage areas that link directly to the chemical’s SDS and emergency information. This gives employees and first responders instant access to life-saving data during an incident.

How to Navigate the Maze of Chemical Compliance Regulations

Think of compliance not as a chore, but as the very foundation of a solid chemical management programme. Trying to keep up with the sprawling, ever-changing world of chemical regulations using spreadsheets and binders is a recipe for disaster. It's like trying to navigate a labyrinth blindfolded. A modern digital platform, on the other hand, is your guide through that maze, automating the heavy lifting and keeping you on the right side of the law.

This shift moves your team from a state of reactive panic—scrambling to catch up with a new rule—to one of proactive control. Instead of you having to manually cross-reference your inventory against dense legal documents, the software does it all for you. It becomes the central nervous system for your compliance efforts, connecting what’s on your shelves to the rules that govern it.

Getting to Grips with GHS and CLP for Hazard Communication

The bedrock of modern chemical safety is the Globally Harmonised System (GHS) of Classification and Labelling of Chemicals. In the EU, this is put into practice through the Classification, Labelling and Packaging (CLP) Regulation. Together, they create a universal language for chemical hazards, standardising how we communicate dangers on labels and in Safety Data Sheets (SDSs).

A good chemical inventory programme is built to make CLP compliance almost second nature. When a new chemical arrives, the system doesn't just log its name; it digs into the SDS and pulls out all the critical hazard information.

This data then becomes immediately useful:

- Generate Compliant Labels: You can instantly print accurate labels for any secondary containers, complete with the right pictograms, signal words, and hazard statements. No more guesswork or human error.

- Maintain an Accurate Hazard Profile: The platform gives you a real-time, bird's-eye view of every hazard present in your facility, from flammable liquids to acute toxins.

- Automate Safety Information: This classified data automatically populates other safety modules, meaning your risk assessments and emergency plans are always based on precise, up-to-date information.

Meeting REACH Requirements for Substance Control

Another giant of EU legislation is REACH—the regulation for Registration, Evaluation, Authorisation and Restriction of Chemicals. It puts the onus squarely on companies to manage the risks of the chemicals they bring to market. A massive part of this is keeping a close eye on Substances of Very High Concern (SVHCs).

This is where a manual system completely falls apart. The SVHC list is constantly being updated, and trying to track every chemical in your inventory against it by hand is a Sisyphean task.

An automated chemical inventory platform is your regulatory watchdog. It tirelessly screens every single substance in your inventory against the latest REACH and SVHC lists, flagging any matches and alerting you immediately.

This proactive screening means you can take swift action, whether that’s sourcing a safer alternative or preparing the necessary paperwork. It turns compliance from a frantic, periodic audit into a continuous, automated background process. This protects your business from the hefty fines that come with getting it wrong. Navigating chemical compliance regulations often involves adhering to specific standards; for instance, laboratories handling hazardous drugs must consult a comprehensive USP 800 Checklist to ensure full compliance.

Managing Transport and International Standards

Compliance doesn't stop at the factory gates. If you're shipping chemicals, you’re bound by stringent transport rules like the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR). A proper chemical inventory system simplifies this headache by generating the required transport documents straight from your inventory data.

For businesses with a global footprint, this becomes even more crucial. The system helps align your operations with international standards, like the Occupational Safety and Health Administration’s (OSHA) Hazard Communication Standard in the US. A centralised platform harmonises your compliance efforts across different legal landscapes, giving you a single source of truth for safe, consistent, and defensible chemical management worldwide.

Selecting the Right Chemical Inventory Solution

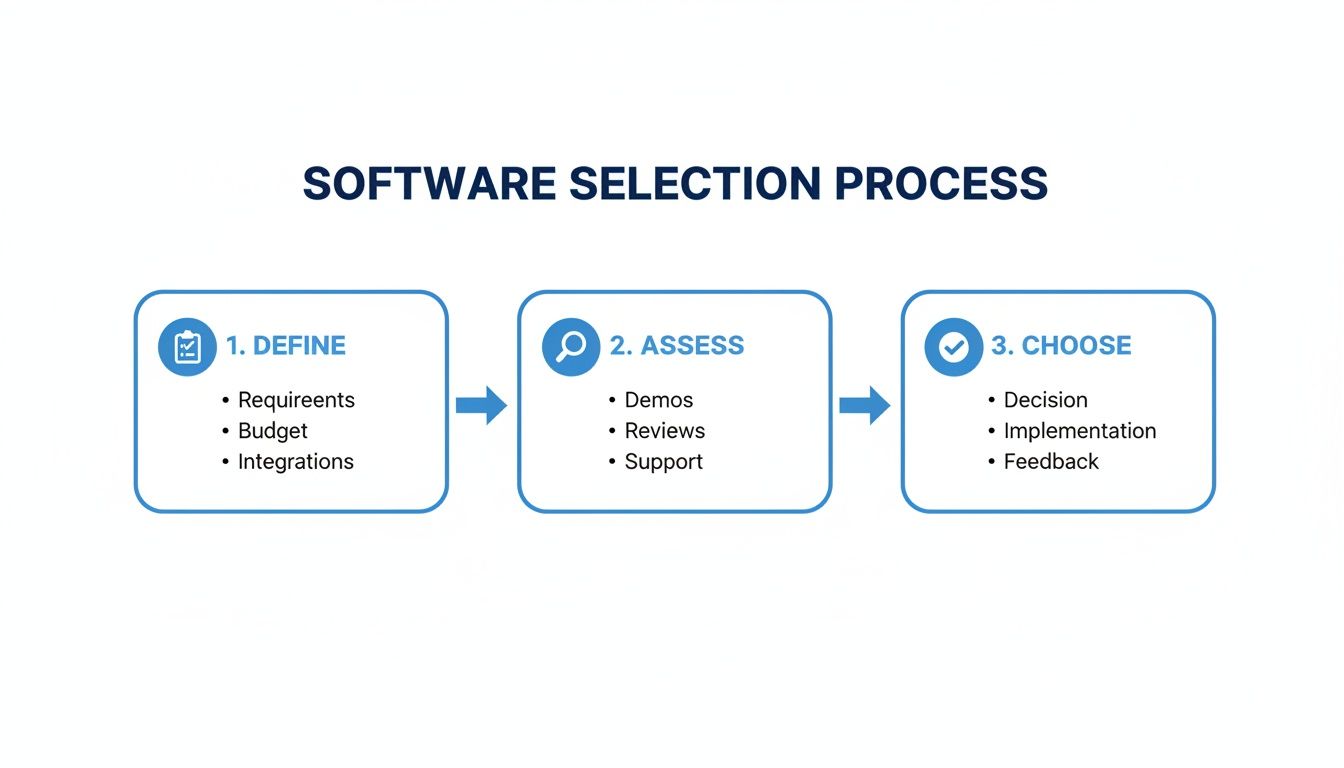

Choosing the right chemical inventory program is one of those big decisions that can ripple through your entire organisation, affecting everything from day-to-day safety to long-term compliance and efficiency. This isn’t just a software purchase; it's about finding a partner that will become the central nervous system for your EHS strategy. Rushing this decision is a mistake, so it pays to take a thoughtful, structured approach that goes well beyond a simple feature list.

The first, and most important, step is to look inward. You need to get crystal clear on what your organisation actually needs. Think about the scale and complexity you're dealing with. Are you a small lab managing a hundred or so chemicals, or a multinational manufacturer juggling thousands of substances across multiple sites? The answer will point you toward the right kind of solution, whether it’s a basic tracking tool or a full-blown enterprise platform.

Define Your Core Requirements

Before you even think about booking a demo, sit down and create a detailed list of what this system absolutely must do. This simple exercise will stop you from getting distracted by flashy features that don’t solve your real, everyday problems. Think of this list as your north star for the entire selection process.

A great way to start is by mapping out your current workflows and pinpointing the biggest headaches. Are your teams spending countless hours manually updating SDSs? Do you lie awake at night worrying about keeping up with REACH regulations? Are you concerned that incompatible chemicals might be stored next to each other in the warehouse? These are the issues that should form the foundation of your evaluation checklist.

Key areas to consider include:

- Automation Capabilities: How much manual drudgery are you trying to eliminate? Look for features like AI-driven data extraction from SDSs, which can genuinely save hundreds of hours a year.

- Scalability: Can the program grow with you? A system that fits perfectly today could become a straitjacket in two years if it can’t handle more users, new sites, or a bigger chemical library.

- User Experience (UX): Is it actually easy to use? A clunky, confusing interface will never get the buy-in from your team, no matter how powerful it is on paper.

Evaluate Critical Functional Criteria

Once you’ve got your core needs nailed down, you can start looking at vendors through a more critical lens. This is where you get into the nitty-gritty of what separates a decent program from a great one. You're looking for a solution that not only solves today’s problems but is also ready for tomorrow’s challenges.

A great chemical inventory solution doesn't just store data; it provides actionable intelligence. It should empower your team to make faster, safer, and more informed decisions every day.

Get ready to ask vendors some tough, specific questions about these crucial functions:

- Integration Potential: Can the software talk to your other systems, like your Enterprise Resource Planning (ERP) platform? Seamless integration is key to avoiding data silos and making sure information flows freely across the business.

- Mobile Accessibility: Can your team pull up critical safety information on a tablet or phone right there on the warehouse floor? Mobile access, often through QR codes, is essential for on-the-spot hazard checks and quick emergency response.

- Data Security: Find out where your data will be hosted and what security protocols are in place. For any business operating in the UK or EU, ensuring your data is hosted in Europe and is fully GDPR-compliant is an absolute must.

Choosing the right software is a significant investment in your company’s safety and future. For a deeper dive, check out our guide on selecting a chemical inventory management system. By taking a methodical approach, you can find a platform that delivers real, lasting value and becomes a cornerstone of your safety culture.

Chemical Inventory Program Selection Checklist

To help you stay organised during the evaluation process, we’ve put together this checklist. Use it to compare potential solutions and guide your conversations with vendors to ensure you cover all the essential bases.

| Feature/Criteria | Key Questions to Ask | Importance (High/Medium/Low) |

|---|---|---|

| SDS Management | How are SDSs sourced and updated? Is the process automated? Does it support multiple languages and regional formats? | High |

| Regulatory Compliance | Which regulations (e.g., GHS/CLP, REACH, OSHA) does the system screen against? How often is the regulatory database updated? | High |

| Data Extraction | Does the system automatically extract data points like CAS numbers, hazard classifications, and PPE from an SDS? How accurate is this extraction? | High |

| User Interface (UX) | Can we get a trial or sandbox environment to test usability? How much training is typically required for a new user? | High |

| Inventory Tracking | Does it track quantities, locations (down to the shelf level), and container status? Can we use barcodes or QR codes? | High |

| Reporting & Analytics | What kinds of standard reports are available (e.g., SARA Tier II, hazardous substance lists)? Can we create custom reports? | High |

| System Integration | Do you have an open API? Have you integrated with ERP or EHS systems like ours before? | Medium |

| Mobile Access | Is there a dedicated mobile app or a mobile-responsive web version? What features are available on mobile devices? | Medium |

| Chemical Labelling | Can the system generate GHS-compliant labels in various sizes? Are the templates customisable? | Medium |

| Implementation & Support | What does the onboarding process look like? What are your standard support hours and response times? Is support included in the subscription? | High |

| Scalability & Security | What is the user/site limit? How is our data protected and backed up? Where are the servers located? | High |

This checklist isn't exhaustive, but it provides a solid framework for making an informed decision. By focusing on these key areas, you'll be well-equipped to choose a chemical inventory solution that truly fits your organisation's needs.

Getting Your Programme Up and Running for Maximum Impact

Rolling out a new chemical inventory programme isn't like flipping a switch; it's more like laying the groundwork for a new building. Even the most powerful software is useless if your team doesn't use it properly. That’s why a careful, step-by-step approach—one that values people and processes as much as the technology itself—is essential for getting it right from day one.

The journey starts with the data you already have. Trying to pour messy, incomplete, or just plain wrong information into a shiny new system is a classic recipe for disaster. The first, and arguably most important, stage is to get your house in order by collecting and cleaning up all your existing data.

This is your chance to finally pull together all those scattered spreadsheets, dusty binders, and random supplier emails into one organised source of truth. For most businesses, this initial clean-up is a real eye-opener, revealing just how chaotic their chemical data has become over time.

Stage 1: Data Migration and System Set-Up

Once your data is tidy, you can start moving it into the new platform. This means migrating your entire SDS library and all your inventory lists. Thankfully, modern solutions like NextSDS make this far less painful with tools that can automatically pull in and process huge amounts of information, cutting down on manual entry and the inevitable human errors that come with it.

With the data loaded, the next job is to mould the system to fit your company's unique shape. This is definitely not a one-size-fits-all situation.

Key set-up steps include:

- Defining User Roles: Assign specific access levels. Warehouse staff might only need to view SDSs, while your EHS manager will need full administrative control to run reports and manage the system.

- Setting Up Locations: You need to digitally map out your physical world. This means defining all your sites, buildings, and even specific storage rooms or cabinets within the software so you know exactly what’s where.

- Customising Alerts: Set up automatic notifications for things that matter to you, like an SDS that’s about to expire, low stock levels for a critical chemical, or a regulatory update that affects a substance you use.

The diagram below shows the kind of thinking that should happen before you even get to this stage, ensuring the system you've picked is actually ready for this kind of customisation.

This just goes to show that a smooth implementation really begins with a smart selection process. When the tool is a perfect fit for your needs, everything else falls into place more easily.

Stage 2: Training and a Phased Rollout

Now that the system is ready, it's time to get your people ready. Proper training is completely non-negotiable, and it needs to be tailored to the audience. What a lab technician needs to know is worlds away from the requirements of a procurement officer or a forklift operator.

One of the biggest mistakes we see is companies running a single, generic training session and calling it a day. Good onboarding is an ongoing process that connects the software’s features directly to the real-world tasks each employee does every day.

To avoid overwhelming everyone, a phased rollout is usually the best bet. You could start with a single department or one site as a pilot programme. This gives you a chance to gather feedback, iron out any wrinkles in the process, and create a small group of "super-users" who can help champion the system when you launch it more widely.

This controlled approach leads to a much smoother transition and gets more people on board across the entire organisation. For a deeper dive into these strategies, check out our guide to chemical inventory management.

Measuring the Success and ROI of Your Programme

So, how do you prove to the higher-ups that investing in a proper chemical inventory programme was the right call? It’s one thing to say things feel smoother, but leadership speaks the language of data and financial sense. The key is to translate your operational wins into a clear-cut business case built on efficiency, risk reduction, and a solid return on investment (ROI).

A huge part of this is looking at the programme's impact on your bottom line. A well-run chemical management system can make a real dent in reducing total cost of ownership by cutting out waste, streamlining how you work, and most importantly, helping you dodge those eye-watering compliance penalties. The justification comes from both hard numbers and some powerful, less tangible benefits.

Tracking Key Performance Indicators

To measure success, you first need to decide what it actually looks like for your organisation. This is where Key Performance Indicators (KPIs) come in. These aren't just vague ambitions; they are the specific, trackable metrics that will show, over time, the real impact your new programme is having.

A smart first step is to benchmark your performance before you implement the new system. This gives you a clear baseline to measure against, so you can see just how far you’ve come.

Some of the most valuable KPIs to keep an eye on include:

- Fewer Non-Compliance Incidents: Keep a tally of audit findings or internal warnings related to chemical management. Every reduction is a clear win.

- Time Reclaimed from Admin Tasks: How many hours is your EHS team saving on jobs like manually updating SDSs, pulling reports, or checking chemicals against regulatory lists? That time can now be spent on higher-value safety initiatives.

- Less Chemical Waste: Use the system to pinpoint expired or duplicate chemical stock. Tracking the savings from lower disposal fees and smarter purchasing adds up quickly.

- Quicker Emergency Response: Run drills and time how long it takes for your teams to access critical SDS information. A faster response time is a direct measure of improved readiness.

Calculating a Concrete Return on Investment

Nothing makes the case stronger than a clear ROI calculation. The simplest way to approach this is to weigh the cost of doing nothing against the cost of the solution. Just think about the potential expense of a single fine for non-compliance with a regulation like REACH or CLP. Often, the cost of dodging just one of those fines more than covers the annual subscription for the software.

We can see a real-world example from Belgium's shift to digital chemical inventories after 2015. Back when they relied on manual spreadsheets, their annual reports had a staggering 36% error rate, which led to €3.2 million in fines in 2014 alone. Fast forward to 2023, with 72% of industrial sites having gone digital, and those error rates have plummeted to just 9%. One study even found that e-commerce distributors using automated systems avoided over €65,000 in daily CLP fines.

The true ROI of a chemical inventory programme isn't just about saving money on fines; it's about building a more resilient, efficient, and safer operation from the ground up.

The Unquantifiable but Invaluable Benefits

Of course, not every benefit can be neatly plugged into a spreadsheet. The qualitative advantages of a modern chemical inventory platform are just as critical and add immense value to your business. These are the improvements that truly strengthen your company’s safety culture and operational integrity.

These powerful, real-world benefits include:

- Improved Employee Safety and Morale: When your team knows they have instant access to accurate, up-to-date safety information, it builds confidence. It shows you're serious about their well-being and fosters a much stronger safety culture.

- Streamlined Audits and Inspections: Picture an auditor showing up, and instead of a frantic scramble for paperwork, you can pull up any required document or report in seconds. It transforms a stressful, disruptive event into a smooth, professional process.

- Enhanced Corporate Sustainability Profile: By managing chemicals more effectively and cutting down on hazardous waste, your programme provides tangible proof of your commitment to environmental responsibility. This isn't just good for the planet; it improves your brand's reputation and makes you more attractive to stakeholders.

When you put it all together, the tangible savings and these invaluable benefits make one thing clear: a robust chemical inventory programme isn’t a cost centre, but a strategic investment in operational excellence.

Frequently Asked Questions

How Long Does It Take to Get a Chemical Inventory Programme Up and Running?

The honest answer? It depends. For a small to medium-sized business with reasonably organised data, you could be looking at just a few weeks. The biggest factor influencing your timeline is the state of your current chemical records.

What really speeds things up, though, are the tools available today. Modern systems can automatically pull in Safety Data Sheets (SDS) from your supplier emails and use smart technology to extract all the critical information. This slashes the time you'd otherwise spend on manual data entry, getting you up and running far quicker than you could in the past.

Can a Digital System Handle SDSs in Different Languages and Formats?

Absolutely. In fact, this is one of their biggest strengths. The best platforms use a combination of AI and Optical Character Recognition (OCR) to read and understand data from all sorts of documents—PDFs, scanned papers, you name it—from anywhere in the world.

Multi-language support is a must-have feature. A good programme can spot the vital safety information like GHS pictograms, hazard statements, and CAS numbers and standardise them in your central library, no matter the language of the original document.

A key benefit of a modern chemical inventory programme is its ability to create a single, unified safety language from dozens of different document styles and formats, ensuring consistency and clarity for everyone.

This is a game-changer for any company that sources chemicals internationally. It breaks down language barriers and helps you maintain compliance across a global supply chain.

How Does This Kind of Programme Help with Sustainability Goals?

A solid chemical inventory programme is a huge asset for your sustainability efforts. By giving you a crystal-clear picture of every chemical you have, it helps you spot where you can cut back on hazardous substances or reduce waste by not over-ordering or letting stock expire.

It's also essential for waste management. The system helps you correctly classify hazardous waste streams based on regulations, ensuring everything is properly documented for transport and tracked right through to disposal. This directly supports environmental standards like ISO 14001 and gives you a clear, auditable trail showing your commitment to handling chemicals responsibly. Better usage means a safer workplace and a smaller environmental footprint.

Ready to turn your chemical management from a reactive chore into a real business advantage? NextSDS provides a complete platform to automate compliance, boost workplace safety, and improve efficiency. Book a demo today and see how easy it can be.