When you hear "chemical safety," what comes to mind? For many, it's just about rules and regulations. But at its core, workplace chemical safety is about one thing: making sure every single person who works with or around hazardous materials goes home safe at the end of the day.

It’s a complete system for managing chemicals to prevent injuries, long-term illnesses, and damage to the environment. This means everything from identifying potential risks and implementing controls like proper storage, to training employees on exactly how to handle these substances safely. It's about building a culture where safety isn't an afterthought, but a reflex.

Why Chemical Safety Is Non-Negotiable

Picture this: a maintenance worker, trying to finish up quickly, grabs two unlabeled bottles of cleaning fluid and mixes them in a small, stuffy closet. Within moments, the fumes are overpowering, and a routine task has escalated into a medical emergency.

This isn't a far-fetched scenario. It’s a real-world example of what happens when a solid chemical safety plan is missing. It's a stark reminder that proactive safety isn't just about compliance—it's the foundation of a healthy, productive, and responsible business. It's our moral duty to protect our people.

The Human Cost of Chemical Exposure

The numbers paint a sobering picture. These aren't just statistics; they represent preventable tragedies that affect families and communities.

In 2019, chemical exposures were responsible for a shocking 2 million lives lost worldwide and led to 53 million disability-adjusted life years. This highlights the hidden, yet devastating, impact of chemicals in our daily environments. You can learn more about this on the World Health Organization's website.

For any HSE manager, these figures are a heavy weight. They underscore the immense responsibility of managing the complex web of chemicals present in almost every workplace. A single misplaced Safety Data Sheet (SDS) or an overlooked hazard label isn't just a compliance issue—it's a potential disaster waiting to happen.

The Four Pillars of an Effective Chemical Safety Program

To truly build a resilient safety culture, we need to move beyond just reacting to problems. A strong program is built on four interconnected pillars. Think of them as the legs of a sturdy table—if one is weak, the whole structure becomes unstable. Below is a high-level look at these components, which we'll explore in more detail.

| Pillar | Objective | Key Activities |

|---|---|---|

| Information & Communication | Ensure everyone has access to clear, understandable hazard information. | Managing Safety Data Sheets (SDS), proper GHS labeling, and clear hazard signage. |

| Control & Mitigation | Minimize exposure to chemical hazards through physical and procedural safeguards. | Implementing proper storage, ventilation, and providing Personal Protective Equipment (PPE). |

| Training & Awareness | Empower employees with the knowledge and skills to work safely with chemicals. | Conducting regular training on hazard recognition, safe handling, and emergency procedures. |

| Emergency Preparedness | Prepare the team to respond effectively in the event of a spill, exposure, or accident. | Developing response plans, providing first aid stations, and running emergency drills. |

Each of these pillars supports the others, creating a comprehensive system that protects your team from every angle.

Turning Data into Actionable Safety

The real challenge for safety professionals is to take all that dense, technical chemical data and turn it into simple, clear actions that everyone on the floor can follow. A Safety Data Sheet holds critical information, but it's useless if it’s buried in a binder or locked away in a hard-to-find digital folder.

The goal is to empower your team with the right information at the right time. They need to be able to make safe decisions instantly, without having to hunt for answers.

This is where modern tools can make a huge difference. Digital platforms like EHS software help close the gap between complex regulatory demands and practical, on-the-ground safety. By automating SDS updates, making critical data easy to access, and providing clear guidance, they make the tough job of managing chemical safety much more manageable.

Understanding Chemical Safety Regulations and Labels

Navigating the world of chemical safety can feel like you're trying to decipher a strange language full of acronyms. You see terms like OSHA, GHS, and REACH thrown around, but they all share a single, vital purpose: creating a universal way to talk about chemical hazards.

Think of the Globally Harmonized System (GHS) as the Rosetta Stone for chemical safety. It ensures that the hazard symbols on a chemical drum shipped from Germany are instantly understood by your team on the factory floor in Ohio. This system gives us a standard, predictable way to classify chemical dangers and communicate them on labels and Safety Data Sheets (SDSs).

This consistency is what makes real-world chemical safety possible. It cuts through the noise and confusion, making sure everyone gets the same clear, life-saving information, no matter where they are.

The Chemical's "User Manual": Decoding the Safety Data Sheet

Every hazardous chemical that enters your facility comes with its own instruction book, which we call the Safety Data Sheet (SDS). This isn't just a piece of paper for the compliance binder; it's your go-to guide for everything you need to know about that substance, especially when things go wrong.

The SDS is organized into a standard 16-section format, which is a huge help. It means you can find critical information quickly and predictably. Instead of seeing it as a long checklist, think of these sections as chapters that tell the full story of the chemical—its properties, its risks, and exactly how to handle it.

Here’s a quick look at the sections you'll probably find yourself turning to most often:

- Section 2: Hazard Identification This is the highlight reel. It gives you the pictograms, signal words ("Danger" or "Warning"), and plain-language statements that spell out the risks.

- Section 4: First-Aid Measures When an exposure happens, this is where you’ll find immediate, step-by-step instructions for first responders.

- Section 7: Handling and Storage This part tells you how to store the chemical to prevent accidents, including critical details on what not to store it next to.

- Section 8: Exposure Controls/Personal Protection Here, you'll find the specific Personal Protective Equipment (PPE) needed, like which type of gloves or respirator will keep your team safe.

Knowing your way around an SDS empowers your team to act fast and make the right call, turning a potential crisis into a controlled, manageable response.

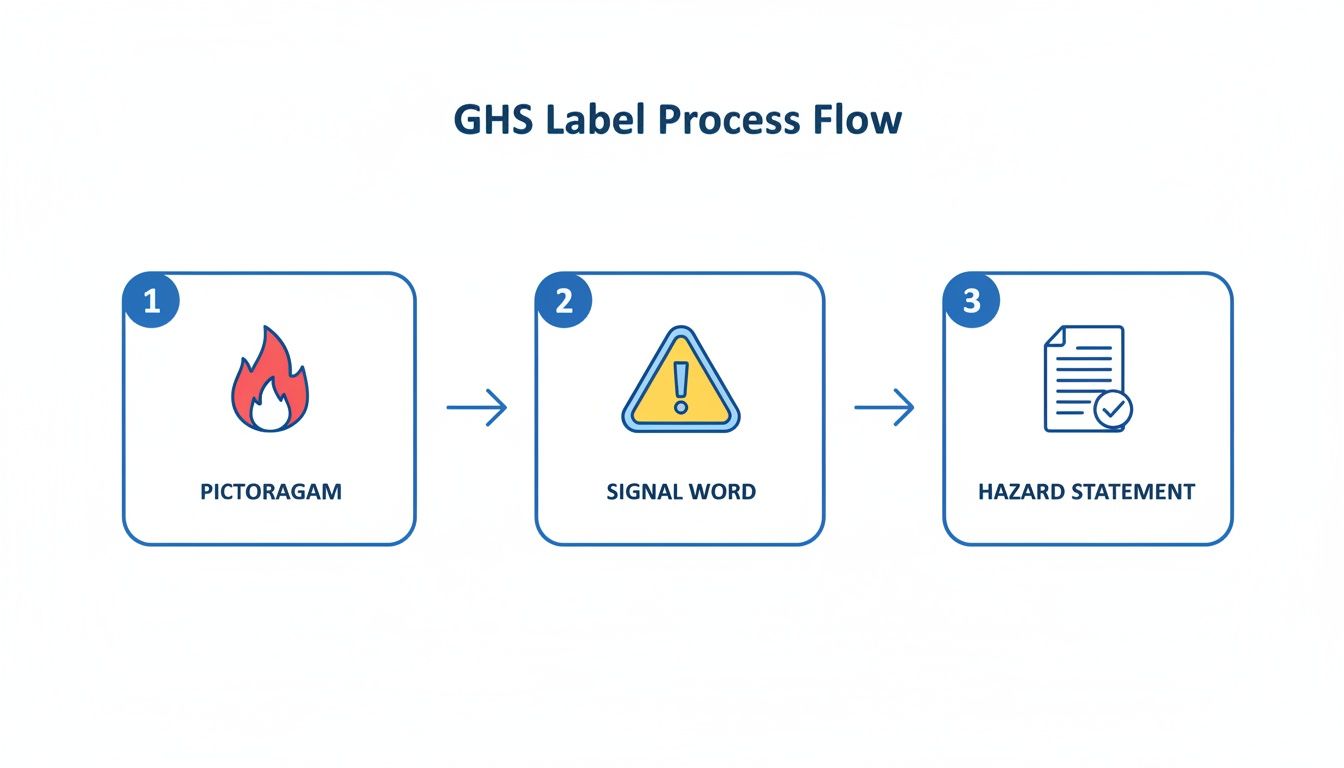

The Visual Language of GHS Labels

Chemical labels are your first line of defense. They tell a quick, visual story about a substance's potential dangers, and the GHS label elements are designed to deliver that story in seconds. You can dive deeper into the specifics in our guide on GHS labeling requirements.

These are the core components you’ll see:

- Pictograms: These are the simple, diamond-shaped symbols that instantly communicate hazards like flammability, corrosion, or toxicity. There are nine GHS pictograms in total.

- Signal Word: Just one word—either "Danger" for severe hazards or "Warning" for less severe ones—immediately tells you the level of risk.

- Hazard and Precautionary Statements: These are short phrases that describe the specific danger (e.g., "Causes severe skin burns") and tell you how to avoid it (e.g., "Wear protective gloves").

Together, these elements turn a simple label into a powerful safety tool. They allow an employee to size up the primary risks of a chemical at a glance—a critical factor in stopping accidents before they ever happen.

Beyond chemical-specific rules, remember that broader Indoor Environmental Quality Standards also play a huge role in overall workplace health. Good ventilation is fundamental to reducing airborne chemical risks.

Thankfully, modern digital platforms have made managing this web of information far more straightforward. They can turn compliance from a reactive headache into a proactive, automated process, ensuring your labels are always right and your SDS library is always current. This shift frees up HSE managers to focus on what really matters: hands-on safety training and preventing risks in the first place.

Building Your Actionable Chemical Safety Plan

A chemical safety plan isn't some binder you write once and then leave to collect dust on a shelf. It’s a living, breathing system that guides what your team does every single day to stay safe. I know, creating one from scratch can feel like a monumental task, but if you break it down into manageable pieces, you can build a rock-solid program that turns good intentions into real-world practice.

Think of it as a blueprint for a safer workplace. The first, most fundamental question you have to answer is: what chemicals do we actually have on site? Without a crystal-clear picture of every substance you’re dealing with, you’re flying blind.

Start with a Comprehensive Chemical Inventory

Treat this step like a financial audit, but instead of tracking dollars and cents, you're tracking potential hazards. A thorough chemical inventory is your master list of every hazardous substance in your facility—what it is, who made it, where it’s kept, and how much you have. This isn't a one-and-done job; it has to be a continuous process.

An accurate inventory is the absolute cornerstone of chemical safety in the workplace. It’s what allows you to spot redundant products, keep an eye on expiration dates, and, most importantly, understand the specific risks lurking in each work area. The old-school clipboard-and-spreadsheet method just doesn't cut it anymore; it's a recipe for errors and quickly becomes outdated.

To get a better handle on modernizing this crucial task, you can see our guide on the benefits of chemical inventory management software. This kind of technology turns a tedious chore into a powerful risk management tool, giving you a real-time, bird's-eye view of your entire chemical landscape.

Digitize Your Safety Data Sheets

Once your inventory is squared away, it’s time to deal with your Safety Data Sheets (SDSs). Let’s be honest, those overflowing binders of paper are a huge liability. When an emergency strikes, nobody has time to frantically flip through hundreds of pages searching for critical first-aid instructions or spill cleanup procedures.

Going digital with your SDS library is a complete game-changer. It puts vital safety information at the fingertips of anyone who needs it, wherever they are, with just a few clicks. This move ensures that your entire team—from the shipping dock to the R&D lab—can pull up the "user manual" for any chemical they're handling, right at the moment they need it most.

A central, digital SDS system is more than just a convenience; it's a piece of critical safety infrastructure. It guarantees every single employee is working off the most current version of an SDS, wiping out the serious risks that come with using outdated hazard or PPE information.

Implement a Foolproof GHS Labeling System

At its core, chemical safety is all about clear communication. The second a chemical gets transferred from its original shipping container into a secondary one—like a spray bottle or a mixing jug—it has to be labeled properly according to GHS standards. An unlabeled container is a dangerous mystery waiting to happen.

A good labeling system tells a chemical's story visually and instantly. This infographic really breaks down the key parts of a GHS label.

As you can see, the pictograms, signal words, and hazard statements all work together to give you an immediate, at-a-glance understanding of a substance's risks.

Master Safe Chemical Storage

Proper storage is about so much more than keeping your work area tidy—it's about preventing fires, explosions, and toxic releases. You wouldn't store fireworks next to a lit candle, and the same common-sense logic applies here. Understanding chemical compatibility is non-negotiable.

Here are the key principles to live by:

- Segregate Incompatibles: Keep acids far away from bases. Store oxidizers separately from flammable materials. Using different cabinets or secondary containment bins is a great way to prevent accidental mixing.

- Control the Environment: Make sure your storage areas are well-ventilated, secure from unauthorized access, and kept at the right temperature.

- Use Proper Containers: Always use containers that are rated for the specific chemical you're storing, and check that they are sealed tightly and in good condition.

Cutting corners on these rules can lead to disaster. Remember, the SDS for each chemical provides specific storage instructions in Section 7—use it.

Prioritize Control Measures and PPE

The best way to manage a chemical risk is to get rid of the hazard altogether. This is where engineering controls, like installing a powerful ventilation system to suck away harmful vapors, come in. When that’s just not feasible, Personal Protective Equipment (PPE) becomes your last line of defense.

Choosing the right PPE is a science, not a guessing game. Section 8 of the SDS spells out exactly what's required, whether it’s nitrile gloves for handling a certain solvent or a full-face respirator for a toxic gas. But just handing out the gear isn't enough. You have to make sure it fits properly and that your team knows exactly how and when to use it.

Train and Empower Your Team

At the end of the day, a safety plan is only as strong as the people carrying it out. Great training transforms employees from passive bystanders into active participants in their own safety. This can't be a one-time thing; it has to be ongoing, engaging, and directly relevant to the specific hazards your team faces every day.

The stakes are incredibly high. Workplace exposure to harmful substances remains a leading cause of serious injuries, with fatalities reaching 820 in 2023 in the US alone. These aren't just statistics; they're preventable tragedies that highlight the urgent need for comprehensive safety programs. A well-trained team is an empowered team—one that has the knowledge and confidence to spot risks and make safe choices, every single shift.

Putting Chemical Safety into Practice Daily

A top-notch chemical safety plan is more than just a binder collecting dust on a shelf. Its real test comes on a busy Tuesday afternoon when production is humming and deadlines are looming. Does the plan hold up? This is where theory hits the factory floor, and a well-designed program gives your team the tools and confidence to make the right call, right now.

Let's walk through two everyday scenarios to see how a practical safety plan moves from paper to practice, highlighting the key moments that make all the difference.

Scenario 1: Tracking a Chemical from Dock to Shelf

Picture this: a new shipment of industrial solvent has just arrived at your loading dock. This is the first link in your safety chain. Before that pallet moves an inch, your receiving team knows exactly what to do.

- Verify What's in the Box: First things first, they confirm the product is what you ordered. They check that the manufacturer's labels are present and easy to read, with all the right GHS pictograms and warnings clearly visible. No guesswork allowed.

- Get the SDS in Seconds: Before signing off, the team lead scans a QR code on the packing slip with a tablet. Instantly, the right Safety Data Sheet (SDS) pops up. A quick glance confirms it’s the most current version.

- Find Its Proper Home: The team checks Section 7 of the SDS, "Handling and Storage." It specifies the solvent needs a cool, well-ventilated spot, far from any oxidizing agents. Now they know precisely where in the warehouse it needs to go.

- Label for the Front Lines: Part of this solvent is needed on the production floor. A worker fills a smaller jug and immediately prints a compliant GHS label for this new, secondary container. This ensures the hazard info follows the chemical wherever it goes.

This smooth, repeatable process stops a hazardous substance from being mishandled or misplaced right at the entry point. It turns the core principles of chemical safety in the workplace into a simple, everyday routine.

Scenario 2: Responding to a Minor Spill in the Lab

Now, let's head over to the lab. A technician is working with a corrosive acid and accidentally knocks over a small beaker. It's a minor spill on the workbench. Instead of panicking, their training and easy access to information take over.

The technician knows better than to just grab a paper towel. They go straight to their workstation, pull up the SDS for the acid, and find their game plan.

Section 6 of the SDS, "Accidental Release Measures," is their go-to guide. It gives specific instructions on how to contain the spill and what to use from the spill kit—in this case, an absorbent neutralizer made for acids.

Following the SDS, they also check Section 8 to confirm the required Personal Protective Equipment (PPE)—chemical-resistant gloves and splash goggles—before safely cleaning up the mess. This is a perfect example of how immediate access to an SDS can turn a potential injury into a minor, controlled incident.

The gap between having safety rules and actually living them can be huge. Since January 2021, the U.S. has seen over 825 hazardous chemical incidents, which resulted in 43 deaths and more than 191 community evacuations. You can dive into a detailed report on these incidents to see just how critical these procedures are.

These numbers aren't just statistics; they're a powerful reminder that robust plans for handling, storage, and emergencies aren't just a good idea—they're essential for protecting lives.

6. Planning for When Things Go Wrong

No matter how robust your safety protocols are, you have to plan for the worst-case scenario. When an incident happens, chaos is your biggest enemy. A clear, well-rehearsed emergency response plan is what separates a controlled event from a full-blown disaster.

This isn't a time for a dense, jargon-filled manual that's locked away in a filing cabinet. Your plan needs to be a straightforward, actionable guide that people can actually use under immense pressure. Think clear, step-by-step instructions for the most likely emergencies: spills, fires, and accidental exposures. In these moments, every single second counts.

Who Does What? Establishing a Clear Chain of Command

In an emergency, the most critical question is, "Who's in charge of what?" Your response plan must spell this out, leaving no room for doubt. Who sounds the alarm? Who calls 911? Who’s grabbing the spill kit?

When adrenaline is pumping, confusion and hesitation can be disastrous. Assigning clear roles ahead of time ensures a coordinated, swift response instead of a panicked scramble. Every employee must know their immediate task, whether it's to evacuate, help a coworker, or begin containment.

A huge part of this is being able to quickly locate and understand safety signs and equipment on site. For instance, understanding fire safety signs like fire hydrant markings isn't just a minor detail; it's critical information that helps first responders contain a chemical fire before it spreads.

Getting the Right Information, Right Now

During a crisis, you need life-saving information in seconds. First responders showing up to a chemical fire don't have time to flip through binders or try to log into a clunky computer system. They need immediate answers: "What chemical is this, and what happens if we put water on it?"

This is where having the right technology makes a world of difference. Imagine a simple QR code on a chemical container or storage cabinet. Anyone—an employee or a firefighter—can scan it with their phone and instantly have the mobile-friendly Safety Data Sheet (SDS) in their hands.

This simple scan closes the dangerous gap between having safety information and using it. It puts critical data—first aid, firefighting measures, required PPE—directly into the hands of the people who need it most, at the exact moment they need it.

In the first moments of a chemical emergency, a few correct actions can drastically reduce the severity of the outcome. Below is a quick-reference table outlining the immediate priorities.

Immediate Actions for Chemical Emergencies

| Priority | Action Item | Key Consideration |

|---|---|---|

| 1: Personal Safety | Assess the immediate danger. Evacuate the area if necessary. | Your safety comes first. You can't help others if you become a victim. |

| 2: Alert Others | Activate alarms and notify supervisors or the designated response team. | A quick, clear alert prevents others from walking into the hazard zone. |

| 3: Isolate the Area | Secure the perimeter to prevent unauthorized entry. | Use caution tape or have someone stand guard from a safe distance. |

| 4: Identify the Chemical | If safe to do so, identify the substance from the container label or SDS. | NEVER approach an unknown substance. Report what you know to first responders. |

| 5: Follow Plan | Consult the SDS and follow the specific emergency procedures outlined. | This includes first aid, spill containment, or fire suppression instructions. |

This checklist isn't a replacement for a full emergency plan, but it reinforces the core "stop, think, and act safely" mindset that saves lives.

Practice Until It's Second Nature

A plan on paper is just a theory. The only way to know if your emergency procedures will actually work is to practice them. Drills aren't about getting a perfect score; they're about finding the weak spots in your plan in a safe, controlled setting.

Run through different scenarios. What happens when there’s a corrosive spill in the lab? A flammable liquid leak in the warehouse? Regular drills transform your written plan from a document into muscle memory. This is how you build the confidence and competence your team needs to act decisively when it really matters. This consistent practice is what makes for a truly resilient chemical safety in the workplace program.

Using Technology to Simplify Chemical Safety

Trying to manage chemical safety with binders and spreadsheets is like navigating a city rush hour with a tattered paper map. It’s clunky, slow, and full of opportunities for things to go wrong. Juggling shifting regulations, chasing down updated Safety Data Sheets (SDSs), and training the team becomes a huge administrative headache that steals time from actual safety work.

This is where modern technology comes in. Digital platforms are built specifically to manage the sheer volume and complexity of chemical inventories, transforming a reactive chore into a smart, proactive system. It’s a change that helps everyone, from the front-line workers to the leadership team.

A Central Command for Chemical Safety

For HSE managers, the relief is immediate. Instead of spending hours hunting down the latest SDS from a supplier, the system handles it automatically. This alone means you're no longer working with outdated, and potentially dangerous, hazard information.

Here’s what that looks like in practice:

- Automated SDS Updates: The platform constantly searches for and fetches the newest versions of your SDSs, so your chemical library is always up-to-date and compliant.

- Real-Time Compliance Alerts: Get an instant heads-up when a chemical in your inventory is impacted by regulatory changes, like being added to the REACH SVHC list.

- Simplified Reporting: You can generate detailed compliance reports in a few clicks, not a few days. That's more time spent on the floor improving safety, not buried in paperwork.

This kind of automation is a fundamental part of today's best chemical safety in the workplace tools. To get a better sense of how these platforms work, it's worth looking into the different types of SDS management software available.

Empowering Your Team on the Floor

This technology also completely changes the game for your employees. The frantic search for a specific binder during an emergency is a thing of the past. Now, critical information is literally at their fingertips.

A simple QR code on a chemical container can be scanned with any phone or tablet, immediately pulling up a mobile-friendly safety card. This gives your team instant access to first-aid procedures, required PPE, and spill response steps—right when they need it most.

This instant access makes your safety program an active, on-demand resource instead of a passive set of rules collecting dust. When you add in features like automated GHS label printing and integrated risk assessments, you create a truly connected safety ecosystem. It’s a system designed to protect your people, reduce your company’s risk, and maintain compliance without the paper-chasing.

Common Questions About Chemical Safety

Even with a great safety program in place, questions are going to pop up. Tackling them head-on is one of the best ways to build your team’s confidence and make sure everyone is on the same page. Let's walk through some of the questions we hear most often from EHS managers and employees alike.

What Is the Most Important Part of Chemical Safety?

If you had to boil it all down to one thing, it would be clear and accessible information. It's the bedrock of everything else. Think about it: if your team doesn't know what they're handling, what the specific risks are, or what to do if something goes wrong, no amount of fancy equipment can truly keep them safe.

This is exactly why having an accurate chemical inventory and easy-to-find Safety Data Sheets (SDSs) is non-negotiable. They are the single source of truth that dictates every other safety decision, from choosing the right gloves to figuring out where a container can be stored.

Who Is Responsible for Chemical Safety in the Workplace?

The short answer? Everyone. While the EHS manager is tasked with building and managing the program, safety is a team sport. It’s a shared responsibility that touches every single person who works with or even near hazardous materials.

A strong safety culture isn't just a binder on a shelf; it's when every individual takes personal ownership. It means employees feel comfortable speaking up about a potential hazard, asking questions when they're not sure, and actively looking out for their coworkers.

Leadership has to set the tone, but it's the folks on the floor who are the real first line of defense.

How Often Should We Provide Chemical Safety Training?

OSHA sets the baseline: you must provide training when an employee is first assigned to a task and anytime a new chemical hazard is introduced. But the companies that truly excel at safety don't just check the box—they go further.

Best practice often involves annual refresher training to keep these critical concepts fresh. Even better, many teams use short, informal "toolbox talks" to zero in on specific topics, like a refresher on GHS labels or a quick rundown of a new chemical's handling procedures. The goal is consistent reinforcement, not just a one-and-done event.

What Should I Do If I Find an Unlabeled Container?

First rule: never, ever use it. If a container has no label, you have absolutely no idea what's inside, how dangerous it is, or what kind of protection you need. It’s a complete unknown.

Here’s the right way to handle it:

- Do Not Touch It: Just leave the container exactly where you found it.

- Isolate the Area: If you can, block off the immediate area to keep others away.

- Report It Immediately: Find your supervisor or EHS manager and let them know right away.

Your company will have a specific protocol for identifying the substance or having it disposed of as hazardous waste. Guessing is the fastest way to cause a serious, preventable incident.

A proactive approach using a tool like NextSDS can get you ahead of these common problems. When you centralize your SDS library, automate GHS label printing, and give your team instant QR code access to safety information, you're handing them the clear, accessible data they need to stay safe. You can learn more about how NextSDS works.