Imagine having a complete, trustworthy history for every single product you manufacture or sell, all available with a quick scan. That’s the core idea behind the Digital Product Passport (DPP). It’s a mandatory digital record that tracks a product’s entire story—from its raw materials to its end-of-life recycling—all in the name of building a more sustainable, circular economy.

Unlocking Supply Chain Transparency with the DPP

The Digital Product Passport is a central piece of the EU's Ecodesign for Sustainable Products Regulation (ESPR). Don’t think of it as just another label; it's more like a dynamic logbook for physical goods. Just as a car’s logbook holds vital information like its service history and technical specs, the DPP provides a comprehensive, verifiable record for everything from batteries to clothing.

Its main goal is to drive transparency right through the value chain. This gives both consumers and businesses the real data they need to make genuinely sustainable decisions. By making information about a product's origins, chemical makeup, and environmental footprint easy to access, the DPP turns sustainability from a vague marketing claim into a verifiable fact.

For businesses in Belgium and right across the EU, this isn't optional. Any company placing covered products on the European market will have to comply. The rollout is happening in phases, with batteries being the first product category affected, and other high-impact sectors set to follow soon after.

To give you a clearer picture, here's a quick summary of what the DPP is all about.

Digital Product Passport At a Glance

| Component | Description | Objective |

|---|---|---|

| Unique Identifier | A unique code (like a QR code) linked to a specific product unit. | Ensures traceability and easy access to data for each item. |

| Data Carrier | The physical tag or code on the product that links to the digital record. | Provides a simple, scannable entry point for consumers and authorities. |

| Data Platform | A decentralised, secure system where all product information is stored. | Guarantees data integrity, security, and accessibility for stakeholders. |

| Standardised Data | Key information points required by the regulations (e.g., materials, footprint). | Creates a common language for sustainability reporting and comparison. |

This framework is designed to connect the physical product to its digital twin, making its entire lifecycle transparent and accountable.

A Rapidly Expanding Mandate

The drive for DPP adoption is kicking off a major economic shift. The global market for DPP solutions was valued between USD 294-338 million in 2025 and is expected to rocket to USD 1,780.5 million by 2030. That’s a compound annual growth rate (CAGR) of a massive 45.7%.

Europe is leading this charge, holding around 38% of the global market share. This puts Belgian businesses in a prime position to adapt and even become leaders in this new regulatory environment. You can dig deeper into these figures by exploring recent research on the digital product passport market.

The core idea is simple yet powerful: attach a unique digital identity to every physical product. This identity unlocks a wealth of information, turning opaque supply chains into transparent networks and empowering every stakeholder with actionable data.

The rollout schedule is absolutely critical for planning. While the regulations will hit batteries first, other product categories are already on the roadmap, including:

- Textiles and Footwear: Will require details on fibre composition, chemical usage, and clear recycling instructions.

- Electronics and ICT Equipment: Focus will be on repairability scores, energy consumption, and the responsible sourcing of minerals.

- Furniture: Will highlight durability, disassembly options, and the use of sustainable materials.

This structured rollout gives businesses a clear—if challenging—timeline to get their data management systems, supplier relationships, and compliance workflows ready for this new era of product transparency.

The EU Regulations Driving DPP Adoption

The move towards the Digital Product Passport isn’t just a passing business trend. It's a legal reality, pushed forward by a very clear and determined strategy from the European Union. For any company operating in Belgium or elsewhere in the EU, getting to grips with these regulations is the first and most critical step to securing market access and staying compliant for the long haul.

At the heart of this new framework is the Ecodesign for Sustainable Products Regulation (ESPR). This is a game-changer. It sets a new bar for almost all physical goods sold in the EU, looking far beyond simple energy efficiency to cover a product's entire lifecycle. The ESPR gives the European Commission the power to set specific ecodesign rules for different product groups, using the DPP as its main tool for transparency and sharing information.

What this really means is that sustainability is no longer a "nice-to-have"—it's a mandatory design feature, fundamentally altering how products are created, sold, and eventually recycled.

The Pioneer: The EU Battery Regulation

While the ESPR lays the broad legal groundwork, the EU Battery Regulation is where the rubber meets the road. It’s the very first piece of legislation to make the DPP mandatory, setting a clear example for every other industry to follow. The rule states that all industrial, electric vehicle, and light mobility vehicle batteries with a capacity over 2kWh put on the EU market must have a digital passport.

Why start with batteries? It’s a strategic choice. Batteries are absolutely essential for the green transition, but they also bring huge environmental headaches, from where we get the raw materials to how we handle them at the end of their life. The battery passport is designed to provide crucial data on material origins, carbon footprint, and recycled content, making it the perfect test case for the wider DPP rollout.

The DPP initiative transforms what we think of as compliance. We’re moving away from static reports and towards active, dynamic data sharing. This creates a connected ecosystem where product information is transparent, verifiable, and available to everyone along the value chain.

A Staggered Rollout Timeline

For HSE and procurement managers, knowing the implementation timeline is key to getting your organisation ready. The rollout is being staggered on purpose to give industries enough time to adjust.

- From February 2027: The DPP mandate officially kicks off, starting with the battery sector.

- 2027-2030 and beyond: Other high-impact product categories will be brought in, with textiles, electronics, furniture, and construction materials at the top of the list.

This phased approach means that even if your sector has a bit more time, the direction is set. You need to start laying the groundwork for data collection, supplier collaboration, and system integration now, no matter what industry you're in. Getting ahead of the curve will be a major competitive advantage. You can learn more about how the DPP impacts chemical compliance in our detailed guide.

This regulatory push is also creating a huge market opportunity. Projections show the Digital Product Passport market is expected to hit USD 7,847 million by 2035, which is a massive indicator of its coming impact. This growth, fired up by the ESPR and other sector-specific rules, is completely reshaping supply chains across all EU member states, including Belgium and Luxembourg.

What’s Actually Inside A Digital Product Passport?

Forget thinking of a Digital Product Passport as just another document. It's more like a dynamic, multi-layered digital file that tells the complete story of a product’s life. This goes far beyond what you'd find on a simple label or even in a traditional Safety Data Sheet (SDS). The data is carefully organised to be useful for everyone, from the end consumer to regulators.

This digital record is built from several distinct data categories, each answering critical questions about the product's journey. While the exact requirements will differ depending on the product type—batteries have different data needs than textiles, for instance—the core pillars of information are remarkably consistent.

Core Data Categories

At its heart, the DPP is structured around a few key information groups:

- Product Identification Data: This is the product's unique fingerprint. It includes the Global Trade Item Number (GTIN), batch numbers, and a unique product identifier that links the physical item to its digital twin, ensuring total traceability.

- Material and Substance Data: Here's where the DPP gets into the nitty-gritty of what a product is made of. It details raw material origins, the percentage of recycled content, and a full list of all substances, flagging any Substances of Very High Concern (SVHCs) under REACH.

- Sustainability and Circularity Data: This layer quantifies the product’s environmental footprint. Think carbon footprint data, water usage metrics, a repairability score, and clear instructions for disassembly and recycling when the product reaches its end of life.

- Supply Chain and Ownership Data: This section creates a transparent view of the product's journey. It logs details about the manufacturer, importers, and even the history of ownership, building a clear chain of custody.

Pulling together this sheer volume of information means businesses will need robust application integration strategies to connect separate systems like PLM, ERP, and supplier portals. Without this, you're just left with data silos.

Going Beyond The Safety Data Sheet

For anyone in Health, Safety, and Environment (HSE), it helps to view the DPP as a major evolution of the familiar Safety Data Sheet. An SDS provides crucial hazard and handling information, and that data absolutely remains a key part of the DPP's substance reporting. But the DPP’s scope is much, much wider.

The Digital Product Passport doesn't replace the need for an SDS; it builds upon it. It takes the chemical safety data you already manage and embeds it within a much broader context of sustainability, circularity, and complete supply chain transparency.

The table below shows how the data points from a standard SDS map directly onto the expanded requirements of a DPP.

Mapping SDS Data to Digital Product Passport Requirements

| SDS Section (GHS/CLP) | Corresponding DPP Data Element | How DPP Expands on SDS Data |

|---|---|---|

| Section 1: Identification | Product Identification Data: Unique Product ID, GTIN, Manufacturer Details | Adds supply chain traceability, batch/serial numbers, and links the physical product to its digital twin. |

| Section 3: Composition | Material & Substance Data: Full chemical composition, Substances of Concern | Demands greater detail on recycled content, raw material origins, and a broader scope beyond just hazardous ingredients. |

| Section 12: Ecological Info | Sustainability Data: Environmental Impact, Ecotoxicity | Expands from basic ecotoxicity to a full Life Cycle Assessment (LCA), including carbon footprint and water usage. |

| Section 13: Disposal | Circularity Data: End-of-Life Instructions, Recyclability Info | Moves beyond simple disposal advice to detailed disassembly instructions, material recovery potential, and repairability scores. |

As you can see, your current SDS management and chemical compliance work is a foundational pillar for DPP readiness, not a separate task. The data you already gather on chemical composition is the starting point. The DPP then adds those critical new layers of lifecycle information that an SDS was never designed to cover.

To get a head start, you can learn more about optimising your current processes by checking out our guide on SDS data extraction and validation best practices.

This connection is fantastic news for proactive compliance teams. It means the effort you put into maintaining accurate chemical data today directly prepares your organisation for the next wave of product regulation. By seeing your existing compliance framework as the first step towards a DPP, you can strategically build out your data capabilities to meet upcoming EU mandates without starting from zero.

A Practical Implementation Roadmap for Your Business

Moving from theory to a workable plan needs structure. For any Belgian business staring down the barrel of the Digital Product Passport, a phased rollout isn't just a good idea—it’s the only way to manage the complexity and make the transition stick. Let's break this down into manageable stages for your Health, Safety, and Environment (HSE), procurement, and operations teams.

Getting an early start gives you a serious competitive advantage. Putting this off, on the other hand, introduces some hefty risks, especially when it comes to keeping your supply chain moving. Since these rules will apply to anyone selling into the EU or supplying parts for products headed that way, doing nothing could mean getting locked out of your most important markets.

Phase 1: Analyse Your Current State

First things first: you need to know exactly where you stand today. A thorough gap analysis is the bedrock of your DPP strategy. This means taking a good, hard look at your current data management practices to see what you have versus what the DPP regulations demand.

It’s time to ask some tough questions:

- Data Availability: Are we actually collecting the data we need on material origins, substance makeup, and carbon footprints from our suppliers right now?

- Data Systems: Can our current systems, like our ERP or PLM software, even handle this level of detailed information?

- Supplier Readiness: How prepared are our key suppliers to send us DPP-compliant data? Let's be honest about it.

This initial assessment will shine a light on your biggest weak spots, helping you figure out where to focus your energy first.

Phase 2: Aggregate Data and Select Technology

Once you've mapped out the gaps, the next step is to start building the bridge to cross them. This involves two things happening at once: pulling all your data together and picking the right technology. You need to create a central hub—a single source of truth—for every bit of product sustainability and compliance data you have.

This means dragging information out of all the different places it’s been hiding. Your chemical compliance data, those supplier sustainability reports, and your own internal manufacturing metrics all need to be brought into one place.

At the same time, you need to find the right platform to manage all of this. Don't even think about using spreadsheets; they won’t scale. Look for a solution that can automatically pull in data, check it against regulatory lists, and connect smoothly with the software you already use.

Think of it like this: the goal is to create a unified data ecosystem where information flows effortlessly from your suppliers, through your own systems, and out into a perfectly compliant Digital Product Passport. This ecosystem is what will power your entire DPP strategy.

Phase 3: Establish Supplier Protocols

Your DPP is only as strong as the data coming from your supply chain partners. This phase is all about setting up clear, non-negotiable rules for getting compliant data from every single supplier. This is a big job that requires a lot of communication and teamwork.

Start by creating a Supplier Data Requirements document. This should spell out exactly what data points you need, the format they must be in, and how suppliers should submit them. You'll likely need to offer some training or resources to help your smaller suppliers get up to speed.

For businesses putting together a DPP roadmap, it's useful to look at established verification methods. For instance, the frameworks in a guide to the ISO 9001 audit process can offer a solid template for checking supplier data and ensuring quality control.

Phase 4: Integrate and Go Live

The final stretch involves plugging your new DPP system into your core business platforms, like your ERP and PLM. This step is crucial. It ensures DPP data isn't stuck in a silo but becomes part of your day-to-day operations, influencing everything from purchasing choices to new product designs.

This is also the time for serious testing. Run pilot programmes with a few trusted suppliers and get your internal teams trained up. Once you're confident the system is stable and the data is flowing correctly, you can start rolling it out across your product lines, beginning with those most affected by the upcoming regulations.

Look at Germany for a glimpse of the future. Our neighbour currently accounts for about 26% of Europe's DPP market and is growing at an incredible 42% CAGR. This rapid uptake in a key market is a clear signal for Belgian businesses: act now to stay competitive and avoid being left behind. You can explore more insights into the DPP market growth.

Using Technology to Automate DPP Compliance

Let's be blunt: trying to manage the data for a Digital Product Passport by hand is a recipe for disaster. It’s simply not feasible. If you’re thinking of using spreadsheets or legacy systems to track every substance, supplier certificate, and sustainability metric, you’re heading straight for compliance failures, expensive mistakes, and crippling operational delays. The sheer amount of data involved will bury any manual process.

Human error is inevitable in that scenario, and your compliance efforts will never keep up as your business grows or regulations change. This is the point where technology stops being a ‘nice-to-have’ and becomes absolutely essential. Frankly, modern automation platforms are the only realistic way to turn this overwhelming compliance burden into a manageable, even strategic, part of your business.

Shifting From Manual Burden to Automated Efficiency

The real headache with the digital product passport is getting all the data together and making sure it's correct. You have to gather information from countless suppliers, force it into a standard format, and then constantly check it against ever-changing regulations like REACH and its SVHC list. Doing this by hand is not just painfully slow; it's practically guaranteed to introduce errors that could get you fined or even blocked from the market.

This is where automated platforms completely change the game. They are built to do the heavy lifting, creating a smooth and repeatable process for managing your DPPs.

The ultimate goal is to create a single, reliable source of truth for all your product data. Technology makes this possible by building an automated ecosystem where information is pulled in, checked, and updated with minimal human oversight, guaranteeing everything stays accurate and consistent.

Imagine, instead of chasing suppliers with endless emails, an automated system handles the communication, pulls in documents like Safety Data Sheets, and intelligently extracts the exact data needed for a DPP. This frees up your team from drowning in admin so they can focus on what really matters: strategic compliance oversight.

The Role of AI in DPP Automation

Artificial intelligence (AI) is what makes truly effective DPP compliance possible. AI-powered systems can handle tasks that are well beyond human capacity, bringing a new level of smarts and efficiency to the entire process.

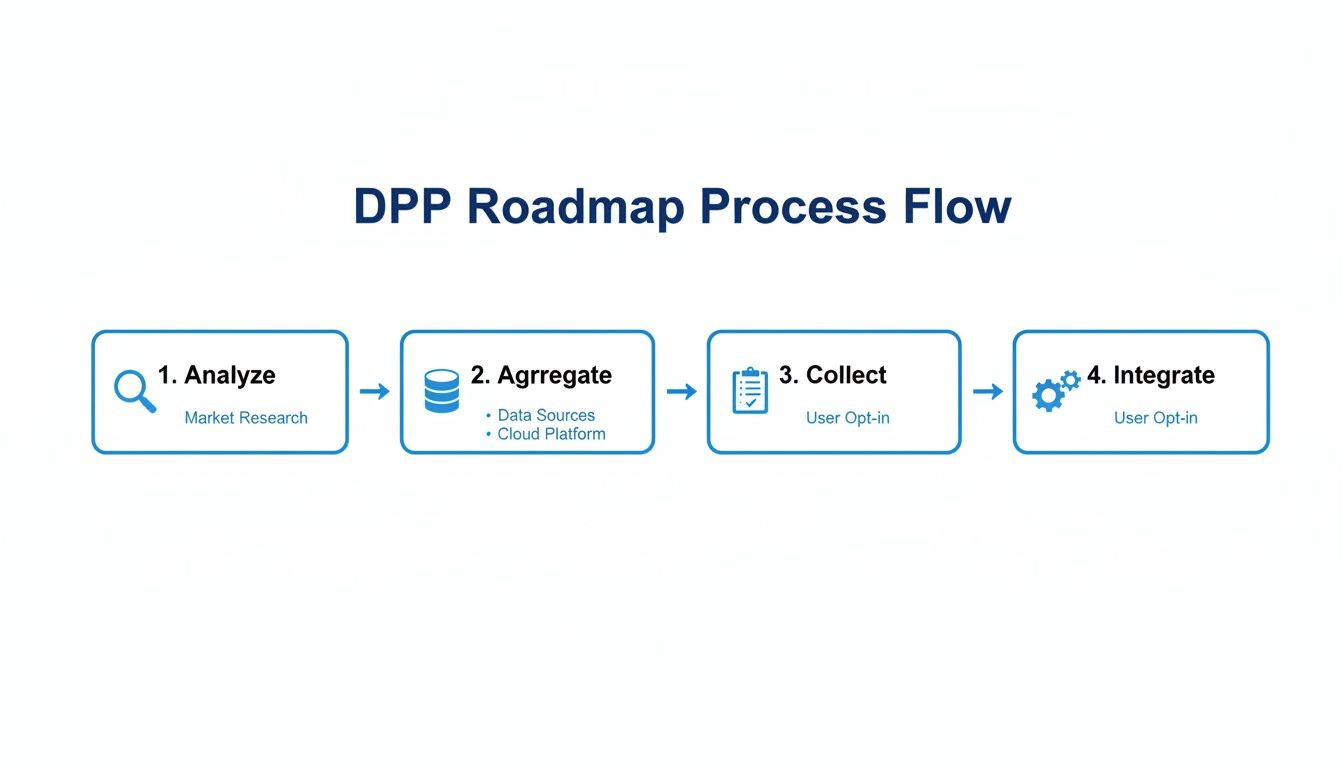

This process flow shows the main stages of putting a technology-driven DPP system in place, from the initial analysis all the way to full integration.

Each step here relies heavily on automation to manage the scale and complexity, ensuring the final system is both robust and compliant.

Here’s a look at how AI helps in practice:

- Intelligent Data Ingestion: AI can take almost any document format from your suppliers—PDFs, XML files, even spreadsheets—and automatically pull out the critical data points like CAS numbers, substance percentages, and where materials came from.

- Automated Validation and Screening: As soon as the data is extracted, the system can check it against thousands of global regulatory lists in an instant. It will immediately flag restricted chemicals or highlight missing information, so you know every product record is complete and compliant before it’s finalised.

- Ongoing Regulatory Monitoring: Regulations never stand still. AI-driven platforms watch for global regulatory updates in real-time. If a substance in one of your products suddenly gets added to a restricted list, the system sends an automatic alert, giving you time to react.

By automating these crucial jobs, technology slashes your risk and helps your business stay compliant, even as the rules change. If you're curious about how this applies to existing chemical management, you can read more about the future of SDS management with AI and automation. Adopting these tools is the surest way to get ahead of the regulatory curve and turn DPP compliance from a challenge into a real competitive edge.

Turning Compliance Headaches into Business Opportunities

Let’s be honest: adapting to the Digital Product Passport framework won’t be a walk in the park. It’s easy to see it as just another compliance hoop to jump through, but that would be missing the bigger picture. While there are real hurdles to clear, the companies that get ahead of this shift will find it’s less of an obligation and more of a strategic investment in a stronger, more reputable business.

The immediate challenges are pretty clear. First up is the massive task of data standardisation. Trying to pull consistent, quality information from a global supply chain, where every partner has different systems and levels of digital know-how, is a heavy lift. Then there's the critical need to keep all that sensitive data secure. You need rock-solid systems to protect commercial secrets and prevent breaches. And of course, the initial cost of new technology and rethinking old processes can feel steep, particularly for smaller businesses.

But if you can navigate these complexities, you’ll unlock some serious advantages that go way beyond just keeping the regulators happy.

From Regulatory Burden to Competitive Edge

The most obvious win is a major boost to your brand reputation. We live in an age where customers look past the marketing fluff and demand real proof of sustainability. The DPP gives you just that—verifiable, data-backed evidence of your product's green credentials. This kind of transparency builds genuine trust and can be the deciding factor for a customer, setting you apart in a noisy market.

It's not just about looking good, either. One recent study projected that DPPs could slash compliance costs in consumer electronics by 15%, saving the industry around €200 million every year. It turns out efficiency and transparency are two sides of the same coin.

The Digital Product Passport transforms sustainability from a marketing slogan into a verifiable, data-backed asset. It provides the proof needed to build authentic customer loyalty and differentiate your brand in a market that rewards genuine environmental responsibility.

Beyond the marketing glow, the data flowing through a DPP delivers concrete operational wins. Having a clear line of sight into your supply chain isn't just for compliance; it builds real supply chain resilience. When you truly understand your material dependencies and can see how suppliers are performing in real-time, you’re in a much better position to head off disruptions and make smarter buying decisions.

This newfound clarity feeds directly into operational efficiency. By digitising product information and automating compliance tasks, you cut down on manual errors and speed up internal workflows. Suddenly, your team is free to focus on work that actually adds value, instead of spending their days chasing down paperwork.

Ultimately, the Digital Product Passport is more than a new rule—it's a catalyst for change. The companies that lean into it now won't just secure their place in the market. They'll discover new efficiencies, forge stronger supply chains, and build a brand that connects with today's conscious consumer. It’s a strategic play to become a more competitive and future-proof organisation.

Got Questions About the DPP? We’ve Got Answers

As the Digital Product Passport starts to become a reality, it’s only natural for questions to pop up, especially if you’re working in procurement or health and safety. Let's tackle some of the most common ones we’re hearing from businesses across Belgium.

So, Which Products Actually Need a DPP?

The short answer is: eventually, almost all of them. The Ecodesign for Sustainable Products Regulation (ESPR) is ambitious and aims to cover nearly every physical product sold in the EU. But don't panic—it's not happening all at once.

The rollout is being done in phases to give everyone a chance to get up to speed. First up are batteries, which need to have their digital product passport ready to go by February 2027. After that, the focus will expand to other sectors with a significant environmental footprint, including:

- Textiles and footwear

- Electronics and ICT equipment

- Furniture and mattresses

- Construction materials like steel and cement

It's worth noting that some items, like food, animal feed, and medical products, are off the hook for now. The key is to keep a close eye on the delegated acts from the EU Commission, as they will spell out the exact timelines for your specific industry.

How Will This Affect Small and Medium-Sized Businesses?

There’s no getting around it—if you sell products in the EU, you’re in. The rules apply to everyone, from the biggest multinationals down to the smallest local enterprises. The EU has recognised that this could be a heavy lift for SMEs and has plans for support, but the core requirement to comply stands.

For SMEs, trying to manage DPP compliance with spreadsheets and manual checks is a recipe for disaster. The smart move is to embrace technology early. This isn't just about ticking a regulatory box; it's about making sure you can still do business in Europe.

This is where scalable, cloud-based platforms really shine. They give smaller businesses a cost-effective way to handle all the complex data, run automated checks against regulations like REACH, and work smoothly with their suppliers. It means you don't need a huge IT team to stay compliant, which helps level the playing field.

What’s the Technology Behind the DPP?

Think of the DPP less as a single app and more as a connected system. The part you'll physically see is the data carrier—something like a QR code or an NFC tag attached directly to the product.

When you scan that carrier, it connects you to the product's unique digital passport. This passport is stored in a secure, decentralised system to make sure the information is always accurate and available. While some are looking at blockchain for its security features, the real engine behind it all is a combination of AI and cloud computing. These are the tools that do the heavy lifting: gathering data from suppliers, checking it for accuracy, and managing the sheer volume of information needed to create a compliant passport. The whole system is being built on open standards, so it plays nicely with different company platforms and IT setups.

Ready to turn a complex compliance challenge into a streamlined, automated process? NextSDS uses AI to ingest, validate, and screen all your chemical data, making your organisation DPP-ready. Discover how our platform can become your single source of truth for product compliance by visiting the NextSDS website.