It's a common mistake to think flammable storage cabinets are about preventing fires. They're not. Their real job is fire containment.

The whole point of these cabinets is to buy time. During a fire, they're designed to safely hold hazardous liquids for a set period, giving everyone a critical window to evacuate and allowing firefighters to get on-site before a small flame turns into a full-blown disaster.

Unlocking the Core Principles of Flammable Cabinet Safety

A lot of people think buying any old yellow steel cabinet ticks the safety box. That’s a dangerous and costly assumption. Real compliance comes down to a cabinet's certified construction, where you put it, and how you use it every day—all of which are governed by strict standards.

It helps to think of it less like a simple storage box and more like a fire-rated safe, but one engineered specifically for volatile chemicals. Its mission is to act as a barrier, holding back intense heat and flames just long enough. This containment prevents the liquids inside from hitting their autoignition temperature, which would otherwise trigger explosions and dramatically escalate the fire.

The Regulatory Frameworks You Need to Know

Around the world, a few key organisations set the rules for storing flammable liquids. In the United States, the main players are the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA). Over in Europe, the benchmark is often EN 14470-1, a tough standard that lays out exactly how fire-resistant safety cabinets must perform.

These aren't just friendly suggestions; they're legally binding rules designed to save lives and protect property. For example, in Belgium, the Royal Decree of 25 January 2001 states that cabinets must hold up against fire for at least 10 minutes (Type 10) or as long as 90 minutes (Type 90), depending on what's being stored and how much. Industrial sites, like those in the Port of Antwerp, often have strict limits, sometimes as low as 50 litres of highly flammable liquids per cabinet.

A compliant cabinet is an engineered safety device. Its double-walled steel construction, self-latching doors, and leak-proof sump aren't just nice-to-haves—they are the core components that deliver life-saving performance during an emergency.

Getting to grips with these foundational rules is the first step in building a truly effective chemical safety programme in the workplace.

The Pillars of Cabinet Compliance

To make sense of all these regulations, it's helpful to break them down into a few fundamental pillars. If you can master these key areas, you'll ensure your facility isn't just compliant on paper but is genuinely safe in practice.

- Certified Construction: The cabinet must be built to meet specific fire-resistance standards, such as EN 14470-1 or NFPA 30.

- Correct Placement: It needs to be located well away from ignition sources and must not obstruct any emergency exit paths.

- Capacity Limits: You can't just fill it up. You must stick to the maximum allowable quantity (MAQ) of liquids permitted inside.

- Proper Use and Labelling: The cabinet must be clearly marked with hazard warnings, and you should only store compatible chemicals together.

The table below offers a quick summary of these essential compliance areas. We’ll dive deeper into each one throughout this guide, but this gives you a solid starting point for understanding what truly matters.

Fundamental Pillars of Flammable Cabinet Compliance

| Compliance Pillar | Key Requirement | Governing Standard (Example) |

|---|---|---|

| Cabinet Construction | Double-walled steel, 38 mm air gap, self-latching doors, leak-proof sump. | NFPA 30 / EN 14470-1 |

| Placement & Siting | Minimum 1-metre clearance from ignition sources and exit routes. | Local fire codes |

| Storage Capacity | Adherence to Maximum Allowable Quantities (MAQs) per cabinet and area. | NFPA 30 / Local Decrees |

| Labelling & Signage | "Flammable – Keep Fire Away" and relevant hazard pictograms visible. | GHS / CLP Regulations |

Getting these four pillars right is non-negotiable for anyone serious about workplace safety. They form the bedrock of a compliant and, more importantly, a safe storage system for flammable liquids.

What Goes into a Fire-Rated Cabinet? Construction and Standards Explained

On the surface, most flammable storage cabinets look pretty similar—usually a sturdy, yellow steel box. But what separates a compliant cabinet from a simple metal cupboard is how it performs when things go wrong. The real difference lies in its certified construction and, crucially, its fire rating.

Think of a fire rating as the cabinet's promise: "I can protect what's inside me from a fire for a set amount of time." This isn't about making it fireproof forever. It’s about buying you precious minutes to evacuate staff and give emergency services a fighting chance to control the blaze before it gets worse.

Understanding Fire Resistance Ratings

Here in Europe, the benchmark standard is EN 14470-1. This regulation grades cabinets on the number of minutes they can shield their contents from the intense heat of a fire, keeping the internal temperature below the point where flammable vapours could ignite.

You’ll see three main ratings on the market:

- Type 30: Guarantees 30 minutes of fire resistance. This is often the minimum you'd want for smaller workshops or areas where a quick escape is straightforward.

- Type 60: Offers a solid 60 minutes of protection. It's a popular choice for many industrial and commercial sites, striking a good balance between safety and cost.

- Type 90: Provides a robust 90 minutes of fire resistance. This is the gold standard, absolutely essential in large facilities, high-rise buildings, or anywhere with complex evacuation plans where every second is vital.

Choosing the right rating isn't a random decision; it should be driven by your site's risk assessment. A Type 90 cabinet in a sprawling chemical plant gives you a 90-minute window—that’s a huge buffer that could easily be the difference between a minor incident and a catastrophe. For context, the common North American standard, NFPA 30, has a different test, requiring a cabinet to keep its internal temperature below 163°C (325°F) for 10 minutes in a fire test.

The Engineering Behind the Protection

A certified cabinet is a masterclass in safety design. Every single part is there for a reason, working together as an active defence system when exposed to extreme heat.

It all starts with its double-walled steel construction. Most high-quality cabinets are built from steel at least 1.2 mm thick, with an insulating air gap of around 38 mm between the inner and outer walls. This gap works just like a double-glazed window, creating a thermal barrier that massively slows down heat transfer from the fire outside to the flammable liquids inside.

Every element of a flammable cabinet is deliberate. From the air gap that insulates it to the seals that expand under heat, the whole system is engineered to delay the moment stored chemicals could ignite and turn a manageable fire into an explosive disaster.

But the double walls are just the beginning. A few other non-negotiable features are needed to meet the strict flammable storage cabinet requirements.

The Critical Safety Features That Really Matter

Beyond the tough exterior, several clever mechanisms kick in during a fire to seal the cabinet tight. Knowing how these work makes it clear why a certified cabinet is a necessary investment, not just a tick-box exercise.

Key Construction Features:

- Self-Latching Doors: These aren’t your average cupboard doors. They use a three-point latching system that secures the door at the top, centre, and bottom. This stops the doors from buckling and bursting open under intense heat—an event that would instantly expose the contents to the fire.

- Intumescent Seals: These are the quiet heroes of the cabinet. Tucked into the door frame, these seals look unassuming at normal temperatures. But when the heat ramps up, they expand to 20-30 times their original size, creating a dense, fire-proof barrier that blocks flames, smoke, and hot gases from getting inside.

- Leak-Proof Sump: At the bottom of every cabinet, you'll find a built-in, liquid-tight sump. Its job is simple but critical: to contain any spills or leaks from the containers inside. This prevents flammable liquids from seeping out and feeding the fire on the floor.

When you put all these pieces together, you get more than just a steel box. You have a tested, certified safety system designed to save lives and protect your property when it counts the most.

Managing Storage Capacity and Chemical Segregation

Two of the most common—and dangerous—mistakes I see with flammable storage cabinets are overloading them and mixing chemicals that should never meet. Getting this wrong isn't just about a potential fine; it's about creating the perfect conditions for a chemical reaction or a fire that spreads uncontrollably. Nailing your storage capacity and segregation is the bedrock of a solid chemical safety plan.

It’s a bit like the old saying, "don't put all your eggs in one basket." This is especially true when it comes to flammable liquids. If you concentrate too much in one cabinet, you create a single, massive point of failure. The whole point of flammable storage cabinet requirements is to limit the fuel load in any one spot, forcing you to spread the risk across multiple cabinets or dedicated fire-rated rooms.

Understanding Maximum Allowable Quantities

Every certified cabinet is built to hold a specific amount and no more. This is its Maximum Allowable Quantity (MAQ), and it’s not a suggestion—it's an engineered limit tied directly to the cabinet's construction and fire rating. Pushing past this limit means the cabinet can no longer guarantee it will contain a fire for its rated time.

European standards, for instance, are very strict. After EU Directive 2014/34/EU was fully adopted, we saw a significant shift. Compliance with basic storage standards jumped from a worrying 62% before 2016 to a much healthier 89% by 2023. Regulations often cap storage at 120 litres per cabinet for certain liquids. A 2021 survey in Wallonia, Belgium, revealed that 34% of sites were still over their limits, leading to serious penalties.

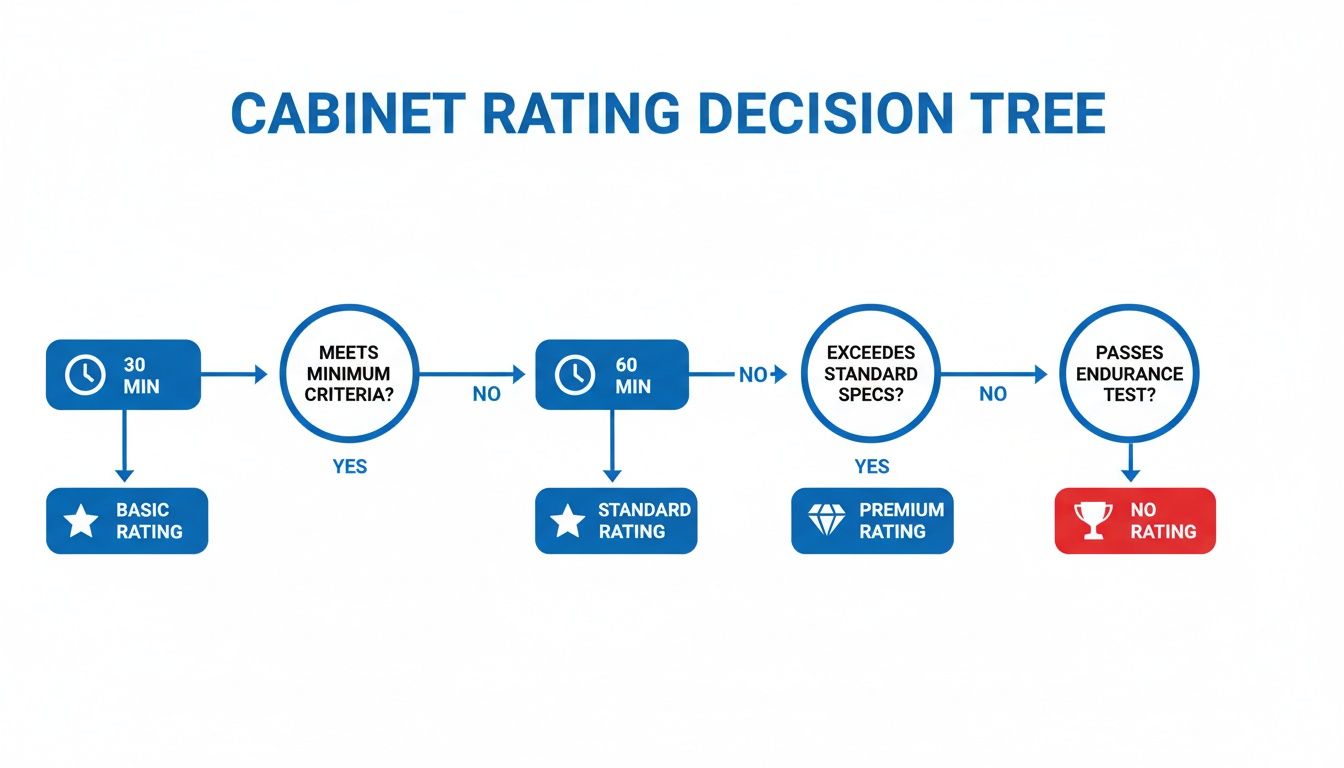

The infographic below gives a great overview of how cabinets achieve different fire ratings (30, 60, and 90 minutes), which is the key factor in determining how much you can safely store inside.

As the decision tree shows, a higher fire rating gives you longer protection in a fire, which is why it's a must-have for high-risk areas and allows for greater storage volumes.

The Critical Rules of Chemical Segregation

Beyond how much you can store, what you store together is just as important. This is a huge part of the broader industrial chemical storage regulations that any facility has to follow. To put it simply, not all chemicals play nicely with each other.

Storing incompatible substances together is like leaving a lit match next to a can of petrol. The danger isn't always immediate, but the potential for disaster is huge.

A flammable liquid cabinet is only for flammables. Storing an oxidiser next to a flammable solvent, or an acid with a flammable base, can create a volatile mixture that could ignite without any external spark or flame.

When the wrong chemicals mix, they can react violently, generating intense heat, toxic gases, or even causing an explosion. For example:

- Oxidisers and Flammables: Oxidisers provide oxygen, which can turn a small, containable fire into an absolute inferno in seconds.

- Acids and Flammables: Many acids are highly corrosive and can eat through containers. A leak could release vapours that then react with nearby flammables.

To illustrate, here’s a look at how European standards like EN 14470-1 categorise liquids and set limits for a single cabinet.

Flammable Liquid Storage Limits Per Cabinet (EN 14470-1 Example)

This table outlines the maximum volume of different classes of flammable liquids that can be stored in a single certified safety cabinet, based on their flash points.

| Flammable Liquid Class (per CLP/GHS) | Flash Point Range | Maximum Volume per Cabinet (Litres) |

|---|---|---|

| Category 1 (Extremely Flammable) | < 23°C, Initial Boiling Point ≤ 35°C | 60 |

| Category 2 (Highly Flammable) | < 23°C, Initial Boiling Point > 35°C | 120 |

| Category 3 (Flammable) | ≥ 23°C and ≤ 60°C | 240 |

| Category 4 (Combustible) | > 60°C and ≤ 93°C | 450 |

Following these limits is crucial for maintaining the cabinet's integrity and ensuring it performs as expected during an emergency.

Using Technology to Ensure Compatibility

Trying to manually cross-reference every chemical against a compatibility chart is a recipe for human error. It’s tedious and, frankly, outdated. This is where a good chemical management system comes in. These platforms use the data from a chemical's Safety Data Sheet (SDS) to automate the segregation process entirely. You can see how complex these relationships get by looking at a detailed https://nextsds.com/blog/chemical-storage-compatibility-chart/ for yourself.

Think of this software as a digital safety officer. When someone adds a new chemical to the inventory, the system automatically flags any potential conflicts with other substances stored nearby. It’s a proactive approach that stops dangerous storage mistakes before they can happen, ensuring you stay compliant and, most importantly, keeping everyone in the workplace safe.

Proper Cabinet Placement and Installation

A certified flammable storage cabinet is a fantastic piece of safety kit, but its real-world effectiveness can be completely undermined if it's stuck in the wrong spot. You can have the best-built cabinet on the market, but proper placement and installation are just as critical as its fire rating. It's like having a top-of-the-line fire engine but parking it where it can't get to the road.

Where you put your cabinet directly impacts how it performs in an emergency. Get it right, and it will do its job: protecting the flammable liquids inside and, more importantly, your people. A badly located cabinet, however, can become a hazard in its own right, turning a safety solution into a dangerous liability.

Finding the Right Location

The golden rule of cabinet placement is separation. You need to put a safe distance between your flammable liquids and anything that could possibly ignite them. This means keeping the cabinet well clear of any potential ignition sources.

And what counts as an ignition source? The list is longer than you might think:

- Welding and Cutting Areas: Sparks from this kind of work can fly a surprising distance.

- Electrical Panels and Outlets: One stray spark from a dodgy connection is all it takes.

- Grinding Machines: These tools are notorious for throwing off hot, incandescent particles.

- Open Flames: This covers everything from space heaters and furnaces to pilot lights on water heaters.

Regulations typically require a minimum clearance of at least 3 metres between your cabinet and any of these potential ignition sources. This buffer zone is crucial—it dramatically reduces the chance of flammable vapours finding a spark and starting a fire.

Just as important is making sure the cabinet doesn't block any escape routes. It must never be placed in a corridor, in front of a doorway, or anywhere that could hinder a quick evacuation during an emergency. Imagine a fire breaking out, only for the escape path to be blocked by the very cabinet meant to contain the hazard. It’s a catastrophic failure of basic safety planning.

The placement of a flammable storage cabinet is a strategic decision, not an afterthought. It must be positioned to minimise risk from ignition sources while guaranteeing it never becomes an obstacle to a safe and rapid evacuation.

Grounding to Prevent Static Ignition

One of the most insidious ignition sources is also one of the most invisible: static electricity. The simple act of pouring a flammable liquid from one container to another can generate enough static charge to create a spark powerful enough to ignite the vapours. This is precisely why grounding is so important.

Grounding (or earthing, as it's also known) gives that static charge a safe path to dissipate harmlessly into the ground, neutralising the threat before it can build up. Most certified cabinets come with a grounding screw connection point for this exact reason. Connecting this point to a verified building earth is a simple, non-negotiable step if you're handling or dispensing flammable liquids. It’s a tiny action that prevents a massive risk.

To Vent or Not to Vent

Ventilation is probably one of the most misunderstood topics when it comes to flammable storage cabinets. Many cabinets are manufactured with two bung-sealed vent openings, which often leads people to assume they should always be left open for airflow. This is a common and dangerous mistake.

Unless you are storing chemicals that give off highly toxic or corrosive vapours that require a mechanical extraction system, the vent bungs should remain tightly sealed. Opening the vents without a proper, professionally installed ventilation system actually compromises the cabinet’s fire rating. It creates a direct pathway for heat and flames to get inside. The flame arresters fitted in the vents are designed to work as part of an active system, not for passive airflow.

For the vast majority of standard flammable liquid storage, keeping those vents sealed is the safest and most compliant choice.

Belgium's significant chemical industry, which contributes 8% to the national GDP, has especially stringent rules for cabinet installation. A tragic fire at a Ghent pharmaceutical plant in 2019, caused by improperly stored materials, resulted in €12.5 million in losses and a three-month shutdown. This event triggered a 40% increase in inspections and far stricter enforcement, serving as a stark reminder of the immense cost of getting placement and installation wrong. You can explore more data on the flammable liquid storage cabinet market.

Labeling, Signage, and Inspection Checklists

Buying a compliant flammable storage cabinet isn't the finish line; it's the start of an ongoing safety commitment. This is where clear communication and regular checks come into play. Think of proper signage and documented inspections as the two pillars that keep your safety asset working effectively, day in and day out.

The labels and signs on a cabinet are its voice. They need to shout a clear warning about the dangers inside to everyone nearby, from seasoned staff to a first-time visitor. This isn’t just a good idea—it's a strict regulatory demand.

Essential Signage for Flammable Cabinets

Every single flammable liquids cabinet needs to have bold, clear warnings that you can't miss, even with the doors shut. These signs are a constant, vital reminder of the hazards and the precautions everyone needs to take.

The most critical signs you'll see are:

- "Flammable – Keep Fire Away": This is the non-negotiable, primary warning. It's direct and leaves no room for misinterpretation.

- "No Smoking, No Ignition Sources Within 3 Metres": This establishes a clear safety zone around the cabinet, banning any activity that could spark a fire.

- Hazard Pictograms: You must display the relevant GHS/CLP pictograms, especially the flame symbol (GHS02), to show the specific type of hazard at a glance.

Getting the labels right on chemicals and their containers is a whole topic on its own, but it's crucial for workplace safety. To get a better handle on these symbols, you can dive into our detailed guide on GHS labeling requirements.

The Power of Routine Inspections

A flammable storage cabinet has moving parts—hinges, latches, seals—that can wear out. The only way to spot a potential failure before it becomes a catastrophe in a fire is through regular, methodical inspections. And just as importantly, you need to document these checks to prove you’re doing your part during any audit.

A documented inspection checklist is your proof of due diligence. It shows you're actively managing the safety of your hazardous materials, turning compliance from a box-ticking exercise into a living part of your safety culture.

A solid inspection should be a systematic walkthrough. The aim is simple: verify that every single safety feature is present and working exactly as the manufacturer designed it to.

To help you put this into practice, here’s a straightforward checklist covering the essential points for any routine inspection.

Flammable Cabinet Inspection Checklist

- Check Cabinet Exterior and Location: Is the cabinet free from dents, corrosion, or other damage? Is it still located well away from ignition sources and not blocking any exit paths?

- Verify Signage: Are all the warning labels clean, easy to read, and firmly attached?

- Inspect Door Mechanisms: Do the self-closing doors swing shut and latch securely on their own from any open position?

- Examine the Spill Sump: Take a look at the sump at the bottom. Is it clean, dry, and clear of any spills or rubbish?

- Review Internal Contents: Are only compatible flammable liquids stored inside? Double-check that no combustible materials like cardboard or oily rags have been stashed in there.

- Confirm Container Integrity: Are the chemical containers inside the cabinet properly sealed, in good shape, and clearly labelled?

These specific checks are vital, but it's always smart to zoom out and look at the bigger picture of facility safety. For a wider view on keeping a safe workplace, a good commercial building inspection checklist can offer great insights into overall compliance.

Common Questions on Flammable Storage Cabinets

When you're dealing with flammable storage cabinets, it’s only natural for questions to pop up. Even if you've got a solid handle on the main regulations, the day-to-day realities of using them can throw a few curveballs your way. This section is all about tackling those common questions, clearing up confusion, and giving you straightforward advice to keep your workplace both compliant and genuinely safe.

Getting these details right really matters. A small misunderstanding can easily create a major safety gap, turning a piece of equipment designed to protect you into a potential hazard. Let's walk through some of the most frequent points of uncertainty one by one.

Can I Store Non-Flammable Chemicals in a Flammable Cabinet?

Technically, nothing is stopping you, but it’s a practice that any safety professional would strongly advise against. Think of a flammable storage cabinet as a highly specialised tool. It’s an expensive, purpose-built piece of equipment designed to do one critical job: protect flammable liquids in a fire. Using it for general storage is a bit like using a surgical scalpel to open a cardboard box – it’s a waste of a vital asset.

More importantly, it creates a serious risk of chemical incompatibility. Imagine you store a strong oxidiser or a corrosive acid right next to where flammable liquids are kept, possibly with lingering vapours. You're setting the stage for a dangerous chemical reaction that could produce intense heat, toxic fumes, or even an explosion. It’s just not worth the risk.

A flammable cabinet should have one job: storing flammable liquids. Keeping them dedicated to this task creates a clear, predictable, and safe system. Mixing their purpose only complicates safety procedures and invites trouble.

Should the Vents on a Flammable Cabinet Be Open or Closed?

This is probably the most common point of confusion out there. The answer is surprisingly simple: unless the cabinet is hooked up to a professionally designed and installed mechanical ventilation system, the vent bungs must stay securely in place.

Many people assume that opening the vents lets vapours escape, but that's a dangerous misconception. An open vent completely undermines the cabinet's fire-resistance rating. It creates a direct path for flames and hot gases to get inside during a fire, defeating the whole purpose of its sealed, double-walled design. The flame arresters on those vents are only designed to work as part of an active extraction system.

So, the rule of thumb is crystal clear: if there’s no mechanical ventilation system attached, keep the vents sealed shut.

How Often Must Flammable Storage Cabinets Be Inspected?

A quick check once a year just isn't going to cut it. To make sure these critical pieces of safety equipment are always ready to do their job, a multi-layered inspection schedule is the way to go.

A really solid inspection routine should look something like this:

- Weekly Informal Checks: This is just a quick, one-minute glance. Are the doors fully closed? Is the warning label visible? Any obvious leaks or damage?

- Monthly Formal Inspections: Time for a more thorough, documented check with a checklist. Make sure the self-closing doors latch properly, the spill sump at the bottom is empty and clean, and that only the right materials are stored inside.

- Annual Comprehensive Review: This is a deep dive. Check the integrity of the intumescent seals around the doors, inspect the hinges for wear, and assess the overall condition of the cabinet. For this, you might even consider bringing in a third-party safety expert.

If your cabinets are in a harsh environment or see a lot of heavy use, you'll want to do these checks more often. And remember, keeping good records isn't just about being organised – it’s your proof of due diligence if an inspector ever comes knocking.

What Do the Different Cabinet Colours Mean?

Colour-coding safety cabinets is a brilliant industry practice that gives you an immediate visual clue about what’s inside. It’s a great system for quick hazard identification, but never forget that the colour is a guide, not a guarantee of compliance.

Here are the most common colours you’ll see:

- Yellow: The universal colour for flammable liquids.

- Red: Typically used for combustible materials like paints and inks, which have a higher flash point.

- Blue: Reserved for corrosive materials, like acids and bases.

- Green: Often used for pesticides and other agricultural chemicals.

While these colours are incredibly helpful for keeping things organised, the most important thing is always the cabinet's official certification and fire rating (like EN 14470-1 or NFPA 30). You must always check the chemical’s Safety Data Sheet (SDS) to confirm the cabinet is the right storage solution. The colour helps you identify it, but the certification is what protects you.

At NextSDS, we understand that managing chemical safety is about more than just having the right hardware. Our platform helps you track, manage, and verify every chemical in your inventory, ensuring you meet flammable storage cabinet requirements and stay ahead of regulatory changes with automated SDS management and real-time compliance monitoring. Discover how you can simplify your chemical safety workflow by visiting https://nextsds.com.