At the heart of workplace chemical safety are the msds requirements for osha, all wrapped up in what’s known as the Hazard Communication Standard. This isn't just a suggestion; it's a rule that requires every employer to have a solid programme in place for communicating chemical risks. The whole point is to make sure every employee can easily get their hands on crucial information through standardised Safety Data Sheets (SDS), clear labels, and proper training.

Getting to Grips With OSHA's Hazard Communication Standard

Think of OSHA’s Hazard Communication Standard (HCS) as the common language everyone speaks when it comes to chemical safety. It’s far more than just red tape. This is the bedrock framework ensuring that the dangers of every chemical produced or imported are properly evaluated and that this critical information gets passed down the line to both employers and the employees who handle them daily.

The mission is straightforward: to uphold every worker's "right to know" and, just as importantly, their "right to understand" the chemical hazards they might encounter. This is done by creating a seamless, consistent pipeline of information that starts with the chemical manufacturer and flows directly to the person using the product.

The Big Switch: From MSDS to SDS

One of the most important updates to this standard was the move from the old-school Material Safety Data Sheets (MSDS) to the modern Safety Data Sheets (SDS). This was much more than a simple name change. Back in 2012, OSHA revamped its Hazard Communication Standard under 29 CFR 1910.1200, officially adopting the 16-section SDS format to align with the Globally Harmonised System (GHS).

This was a game-changer. It standardised the way hazard information is organised, making it far easier for workers anywhere to quickly locate and interpret life-saving data. Now, an SDS from a supplier in Germany has the same layout as one from the US, removing a massive barrier to global safety. For companies operating across borders, this shift created a much more predictable and efficient path to compliance.

Who's Responsible for What Under the HCS?

The standard is crystal clear about who needs to do what to keep the information flowing. The responsibilities are divided to ensure nothing falls through the cracks:

- Chemical Manufacturers and Importers: They're on the hook for classifying the hazards of the chemicals they produce or bring into the country. They must also create the corresponding labels and Safety Data Sheets.

- Employers: Their job is to create a written hazard communication programme, keep an updated library of SDSs for every hazardous chemical at their worksite, and train their teams to understand the risks and the necessary protective measures.

At its core, the HCS operates on a simple, powerful principle: informed workers are safer workers. Giving people clear, accessible information about chemical hazards is one of the most reliable ways to prevent workplace injuries and illnesses.

While getting a handle on the Hazard Communication Standard is a huge step, it’s part of a bigger safety picture that includes other essential construction site safety equipment and procedures. If you want to dig deeper into the specifics, you can find a more detailed breakdown of these https://nextsds.com/blog/osha-requirements-sds-sheets/ in our companion article.

Breaking Down the 16 Sections of a Safety Data Sheet

A Safety Data Sheet isn’t just a piece of paper you file away to tick a compliance box. It’s a detailed safety manual for every hazardous chemical you handle, and it's meant to be a practical tool in your daily safety efforts. The real power of a modern SDS comes from its standardised, 16-section format, a core part of the OSHA MSDS requirements under the Globally Harmonised System (GHS).

This structure wasn't just pulled out of a hat; it organises complex, life-saving information into predictable, easy-to-find segments. When an emergency strikes, nobody has time to hunt through a disorganised document. This layout means you can find critical information—like first-aid measures or firefighting instructions—in a matter of seconds.

Think of it like the dashboard of your car. No matter the make or model, you know exactly where to look for the speedometer, the fuel gauge, and the warning lights. The SDS format works on the very same principle, creating a universal language for chemical safety that everyone can understand instantly.

The First Response Sections

The first few sections of an SDS are all about immediate identification and emergency response. This is the information you need at your fingertips when something goes wrong or when you're first sizing up a chemical's potential dangers.

- Section 1: Identification This first step simply confirms you've got the right chemical. It lists the product identifier, manufacturer contact details, and recommended uses, so there’s absolutely no room for a mix-up.

- Section 2: Hazard Identification Here’s your at-a-glance summary of the risks. It includes the chemical's classification (e.g., flammable liquid, acute toxicity), hazard pictograms, and crucial precautionary statements.

- Section 3: Composition/Information on Ingredients This part breaks down what's actually in the substance. You'll find the chemical ingredients, including any impurities or stabilising additives, and for mixtures, the concentration of each hazardous component.

- Section 4: First-Aid Measures This is your script for an emergency. It provides clear, step-by-step instructions for what to do if someone is exposed through inhalation, skin contact, eye contact, or ingestion.

The Safe Handling and Prevention Sections

Once you move past the immediate response info, the next group of sections provides the technical detail needed for safe handling, storage, and personal protection. This is your playbook for preventing incidents before they ever have a chance to happen.

For any safety professional, these sections are the heart of proactive risk management. They transform the SDS from a document you only look at after an accident into a strategic tool for designing safe work procedures and conducting thorough risk assessments.

Take Section 8, for example. It’s the blueprint for your Personal Protective Equipment (PPE) programme. It doesn't just give a vague suggestion like "wear gloves"; it specifies the exact type of glove material that offers proper protection against that specific chemical.

- Section 5: Fire-Fighting Measures This outlines the right extinguishing techniques, highlights specific hazards that can arise from the chemical during a fire, and lists special protective equipment for firefighters.

- Section 6: Accidental Release Measures Here you'll find the game plan for containing and cleaning up spills or releases, helping to prevent or minimise exposure to people, property, and the environment.

- Section 7: Handling and Storage This details all the precautions for safe handling, including how to prevent fires and which chemicals should never be stored together to avoid dangerous reactions.

- Section 8: Exposure Controls/Personal Protection This absolutely crucial section lists OSHA’s Permissible Exposure Limits (PELs), Threshold Limit Values (TLVs), and the right engineering controls. It also recommends specific PPE for your eyes, skin, and respiratory system.

The Technical and Regulatory Sections

The final group of sections contains deep technical data and regulatory information. While you might not refer to these as often in daily operations, they are vital for environmental compliance, transport, and waste disposal. Section 14, for instance, is essential for your logistics and shipping teams to ensure they're following Department of Transportation regulations.

Interestingly, OSHA only mandates that Sections 1 through 11 and Section 16 are completed, as the information in Sections 12 through 15 is regulated by other agencies. However, any fully GHS-compliant SDS will include all 16 sections.

This table gives a clear overview of the SDS structure, showing how each section plays a specific role in communicating hazard information effectively.

The Mandatory 16-Section SDS Format and Its Purpose

| Section Number | Section Title | Primary Purpose and Key Information |

|---|---|---|

| 1 | Identification | Identifies the chemical, its intended use, and the supplier's contact details. |

| 2 | Hazard(s) Identification | Outlines all hazards of the chemical and displays the required label elements (pictograms, signal words). |

| 3 | Composition/Information on Ingredients | Details the substance's ingredients, including trade secret claims. |

| 4 | First-Aid Measures | Provides instructions for untrained responders on immediate care for exposure. |

| 5 | Fire-Fighting Measures | Lists suitable fire extinguishing techniques and equipment, and chemical hazards from fire. |

| 6 | Accidental Release Measures | Gives guidance on responding to spills, leaks, or releases, including containment and cleanup. |

| 7 | Handling and Storage | Outlines precautions for safe handling and storage, including incompatibilities. |

| 8 | Exposure Controls/Personal Protection | Lists exposure limits (PELs, TLVs) and recommends personal protective equipment (PPE). |

| 9 | Physical and Chemical Properties | Details the chemical's characteristics, such as appearance, odour, pH, and flash point. |

| 10 | Stability and Reactivity | Describes the chemical's stability and the possibility of hazardous reactions. |

| 11 | Toxicological Information | Provides data on routes of exposure and symptoms of both acute and chronic effects. |

| 12 | Ecological Information | Details the chemical's impact on the environment, such as its ecotoxicity. |

| 13 | Disposal Considerations | Gives guidance on proper disposal, recycling, or reclamation of the chemical and its container. |

| 14 | Transport Information | Provides classification information for shipping and transporting the chemical. |

| 15 | Regulatory Information | Lists safety, health, and environmental regulations specific to the product. |

| 16 | Other Information | Includes the date of the SDS's preparation or last revision, providing a clear version history. |

By understanding this structure, you can quickly navigate any SDS, confident that you can find the exact information you need, right when you need it most.

Your Obligations for SDS Management and Accessibility

Just having a Safety Data Sheet stashed away in a filing cabinet won’t cut it with OSHA. The Hazard Communication Standard is crystal clear: it’s not about just having the document, but ensuring "ready accessibility" for every single employee, on every single work shift. This single principle is the bedrock of your responsibility as an employer, turning the SDS from a static piece of paper into a vital, active safety tool.

But what does "ready accessibility" actually look like on the ground?

Imagine a lab technician gets an unexpected chemical splash. They don't have time to hunt down a supervisor for a key, navigate a clunky login process, or flip through a massive, disorganised binder. They need Section 4 (First-Aid Measures) right now. Any delay could make a bad situation much worse.

This is the real-world acid test for your system. OSHA expects employees to be able to get their hands on SDS information without having to leave their immediate work area. There can be no barriers—like forgotten passwords or locked office doors—standing between them and the information they urgently need.

Digital vs. Physical SDS Libraries

Modern workplaces typically lean towards either digital or physical systems for their SDS library. Both are perfectly fine in OSHA’s eyes, as long as they meet that core accessibility requirement. But each approach comes with its own set of practicalities.

- Physical Binders: The old-school three-ring binder is simple, but it demands constant hands-on effort. You'll need to make sure binders are clearly labelled, kept in well-known, accessible spots, and that someone is tasked with physically swapping out old sheets for new ones as they arrive.

- Digital Systems: An electronic library offers fantastic search capabilities and makes updates a breeze. The trade-off? You have to train every employee on how to use it. More importantly, you absolutely must have a solid backup plan for when the power goes out or the network crashes. This could be a dedicated computer on an uninterruptible power supply (UPS) or a locally saved copy of the library.

A common trap is thinking a digital system is automatically compliant. If your staff can’t log in or the server is down, your high-tech library is no more accessible than a locked cabinet, and you're in direct violation of the standard.

This accessibility rule isn't some minor detail; it’s a major focus for enforcement. As laid out in 29 CFR 1910.1200(g)(8), employers must maintain up-to-date SDSs for every hazardous chemical and guarantee employees can get to them immediately during their shift. This applies to every chemical, no matter how small the quantity.

In 2023 alone, OSHA issued over 2,700 citations for Hazard Communication violations. A staggering 25% of those were for failures in SDS accessibility, leading to fines that topped $10 million. These numbers speak for themselves.

The Full Lifecycle of an SDS

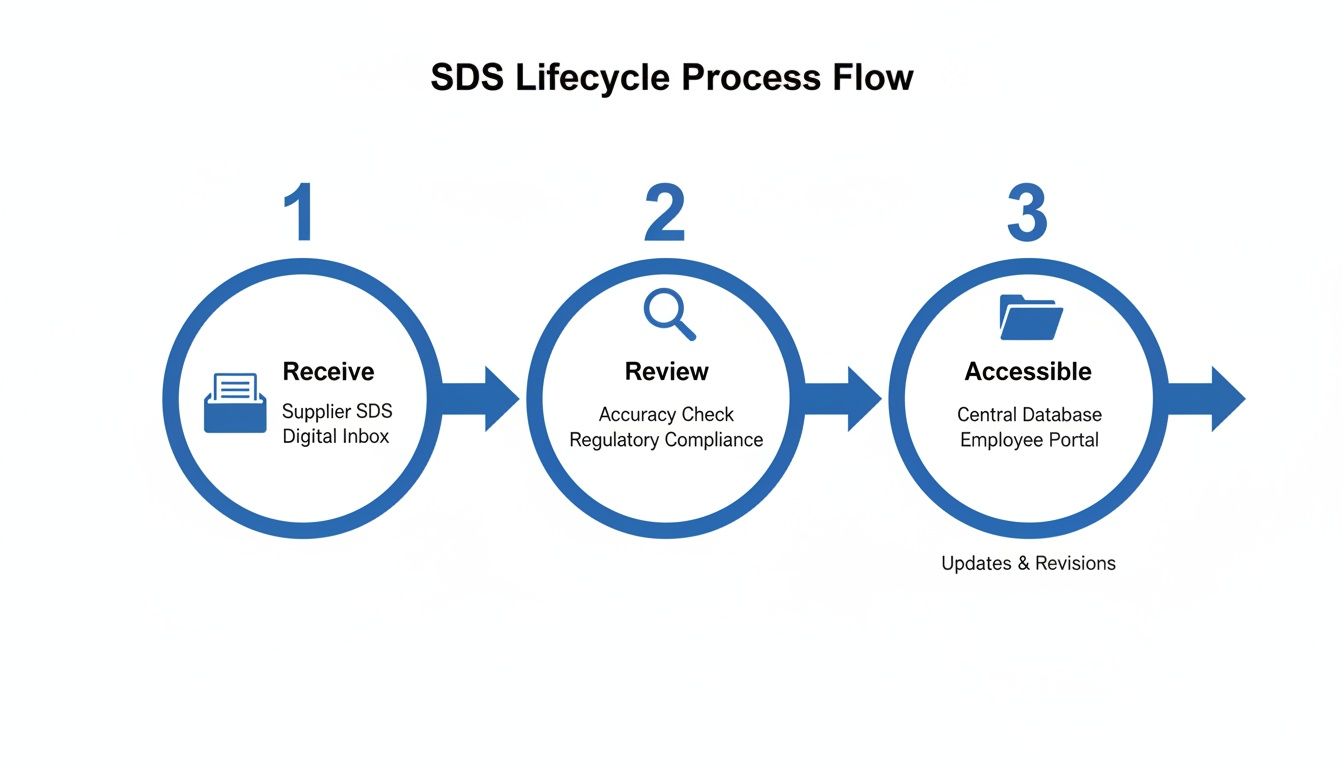

Good management is about more than just storage. It’s about supervising the entire journey of an SDS within your facility, from the moment it arrives on a delivery truck to the day it’s finally archived. A well-defined workflow is your best defence against compliance headaches.

- Receiving and Vetting: As soon as a new chemical comes through the door, its SDS needs to be reviewed. Is it in the proper 16-section GHS format? Is it the latest version from the supplier? Don't just assume it is.

- Integration into the Library: The new SDS must be added to your central library—digital or physical—without delay. This is also the trigger to find and remove any older versions for that same product to prevent any confusion.

- Ongoing Updates and Archiving: Manufacturers are required to update an SDS within three months of learning about new hazard information. While you aren’t expected to proactively hunt down these updates, you must replace your current SDS with any new one you receive. Crucially, you also have to keep old SDSs, often for as long as 30 years after a product is no longer used, to maintain historical exposure records.

Putting together a solid workflow to handle this entire process is non-negotiable. You can learn more about building a complete safety data sheet management system in our dedicated guide. A bulletproof system doesn't just protect your workers; it shields your business from costly fines.

How to Weave SDS Compliance into Your Supply Chain

The best safety programmes don’t just happen when a chemical drum is rolled onto the receiving dock. They start way earlier, deeply embedded in how you buy things. When you start thinking about SDS management as a supply chain function, not just a safety chore, you turn your purchasing team into your first line of defence against chemical hazards.

This mindset shift is about being proactive. It means treating a Safety Data Sheet as a non-negotiable purchasing document, every bit as important as a price quote or a technical spec sheet. By building SDS validation right into your procurement workflow, you stop potential problems long before they set foot in your facility. It's the classic difference between inspecting materials at the source versus finding defects on the assembly line.

Vetting Suppliers Before the Purchase Order

The heart of this strategy is simple: no compliant SDS, no purchase order. Before any new chemical gets the green light for purchase, your procurement team should be asking for and thoroughly reviewing the supplier's SDS. This isn't just a quick glance—it's a formal validation step.

This pre-purchase check should confirm a few crucial details to ensure you are meeting the msds requirements for osha:

- GHS Compliance: Does the document stick to the mandatory 16-section format? Are the pictograms, signal words, and hazard statements correct?

- Completeness: Are all the required sections filled out with clear, useful information? Vague answers or missing data, especially in key areas like Section 8 (Exposure Controls/PPE), should be a massive red flag.

- Revision Date: Is the document current? An SDS that’s several years old might not reflect the latest hazard information or regulatory changes.

Making this a standard operating procedure means you stop non-compliant, mislabelled, or unexpectedly nasty materials from ever being ordered in the first place. You completely avoid the logistical headache and safety risks of dealing with unapproved chemicals that have already landed on your doorstep.

Screening Chemicals Against Restricted Lists

Beyond just checking for basic compliance, your supply chain workflow should also screen potential new chemicals against your own internal restricted substance lists, as well as external regulatory ones. The SDS gives you all the ammunition you need to do this efficiently, like CAS numbers and a breakdown of ingredients.

By vetting chemicals at the procurement stage, you transform your supply chain from a simple delivery channel into a proactive risk mitigation engine. You gain control over what enters your workplace, ensuring every substance has been pre-approved for safety.

For example, a new cleaning solvent might look great on paper, but its SDS could reveal it contains an ingredient on a regulatory watch list, like REACH's list of Substances of Very High Concern (SVHC). Catching this before you buy protects your people and saves you from future compliance nightmares. This process is a vital part of upholding modern msds requirements for osha.

This diagram shows the simple but effective lifecycle for managing every SDS that comes into your facility.

The flow from receiving to reviewing to making the SDS accessible isn't a one-time task; it's a continuous loop that keeps your chemical library current, compliant, and ready for use.

This "upstream" thinking gets your procurement and EHS teams working together, creating a powerful synergy. Procurement folks gain a much deeper understanding of the materials they're sourcing, and safety managers can rest easy knowing that any new chemical arriving on-site has already been properly vetted. It’s a collaboration that builds a safer, more compliant, and more efficient operation from the ground up.

Using Modern Platforms for Smarter SDS Management

If your chemical safety programme is still running on three-ring binders or a messy web of spreadsheets, you’re not just working harder—you’re working with unnecessary risk. Manual systems are notoriously slow, wide open to human error, and simply can't keep pace with the constant stream of updated documents and regulatory shifts. The old way of managing msds requirements for osha is purely reactive, often leaving safety managers scrambling just to keep up.

Modern SDS management platforms offer a far smarter, proactive approach. These systems are built from the ground up to automate the most repetitive and error-prone compliance tasks, fundamentally shifting your programme from a defensive crouch to an offensive strategy. They become the single, reliable source of truth for your entire chemical inventory.

Forget hunting for a binder in an emergency. Imagine an employee scanning a QR code on a container with their phone and having the SDS pop up instantly. That’s the kind of efficiency and reliability technology brings to hazard communication, turning what was once a compliance headache into a genuine operational advantage.

Automation That Drives Compliance

The real power of these platforms is automation. They can automatically pull key data from an SDS, flag documents that are out of date, and even alert you when a chemical in your stock is suddenly affected by a new regulation. This sort of round-the-clock vigilance is something a manual system can never hope to achieve.

This move to digital management isn’t just about making life easier; it's a direct response to the growing complexity of chemical regulations. The switch from MSDSs to the globally harmonised SDS format under OSHA's 2012 HCS update was a huge step forward, aimed squarely at reducing chemical-related incidents. And it worked. OSHA statistics show a massive 60% drop in such illnesses between 1985 and 2020, with much of that success credited to better communication through standardised SDSs.

The financial case is just as strong. With fines reaching a maximum of $156,259 per wilful breach in 2024 and audits in 2023 finding that 18% of facilities had outdated SDSs, automation becomes an obvious investment.

For any organisation ready to leave outdated manual processes behind, embracing modern tools is a game-changer. A great guide to effective compliance risk assessment software can show you how the right technology fosters proactive prevention across your entire operation, not just with your chemical inventory.

A Clear Comparison: Manual vs Automated Systems

Putting automated systems side-by-side with traditional methods makes the advantages crystal clear. The difference isn't just about speed; it's about the fundamental reliability and safety of your entire hazard communication programme.

Moving to an automated system is like swapping a paper map for a GPS. Both might get you there eventually, but one provides real-time updates, alerts you to roadblocks, and finds the most efficient route, ensuring you arrive safely and on time.

To see just how different the day-to-day reality is, let's compare the two approaches.

Manual vs Automated SDS Management

| Feature | Manual Methods (Binders/Spreadsheets) | Automated Platform |

|---|---|---|

| Accessibility | Limited to physical locations; can be lost or damaged. | Instant access via web or mobile app, anywhere, anytime. |

| Updates | Requires manual checking, printing, and replacing of sheets. | Automated alerts for new versions; easy digital replacement. |

| Compliance | High risk of outdated documents and human error. | Screens chemicals against regulatory lists; flags non-compliance. |

| Emergency Response | Slow; requires finding the correct binder and page. | Immediate search function; mobile access for first responders. |

| Record Keeping | Cumbersome archival process; difficult to track revisions. | Automatic version history and secure, long-term archiving. |

In the end, adopting modern technology is about creating a safer, more resilient workplace. These tools don’t just save time and slash errors; they free up EHS managers to focus on high-impact safety initiatives instead of getting buried in paperwork. To see how it works in practice, take a look at our guide on SDS management software.

Of course. Here is the rewritten section, designed to sound like it was written by an experienced human expert.

Your Top OSHA SDS Questions, Answered

Even when you know the rules inside out, the real world has a funny way of throwing curveballs. When it comes to msds requirements for osha, most of the headaches come from those grey areas—the practical, on-the-ground challenges that safety managers deal with every single day. Let's tackle some of the most common questions we hear from people in the field.

My goal here is to give you the confidence to apply the Hazard Communication Standard (HCS) correctly, especially in situations that aren't so black and white. From consumer products in the workplace to suppliers that have vanished, we’ll sort through the nuances that trip people up.

Do We Need an SDS for Common Household Cleaning Products?

This is easily one of the most common questions, and the answer is a classic: "it depends." The deciding factor isn't what the product is, but how it's being used in your workplace.

OSHA carves out a specific exemption for consumer products, but it only applies when they are used in a way that’s basically the same as how you'd use them at home—both in frequency and duration. For instance, if someone in the office occasionally grabs a bottle of glass cleaner to wipe down their own desk, that's considered consumer use. Their exposure is minimal, so no SDS is needed.

But that all changes the moment you put that same bottle in the hands of a professional. If your janitorial crew uses that exact same glass cleaner for hours every day, their exposure is worlds apart from a typical consumer's. At that point, the product is being used in an occupational setting, and it falls squarely under the HCS. You absolutely must have a compliant SDS on hand for that cleaning crew.

What if a Manufacturer Goes Out of Business?

It’s a tough spot to be in, but it happens. A supplier shuts down, and suddenly you can't get an updated Safety Data Sheet for their product. It can feel like you've hit a compliance brick wall, but OSHA’s expectation here is based on what’s reasonable. You are not expected to whip up your own SDS from scratch.

Your main job in this situation is to keep the most recent SDS you have for that product. Just as important, you must document every single attempt you made to get an updated one. This paper trail is your proof of due diligence.

Make sure you keep a clear log of:

- Emails you sent to the company’s last known address.

- Phone calls you made, with notes on who you spoke with (if anyone).

- Any returned mail or "undeliverable" email notifications.

This record shows an OSHA inspector that you made a good-faith effort to comply. It demonstrates that you were proactive, effectively shifting the responsibility when a supplier becomes a ghost.

Can Our Entire SDS Library Be Digital?

Absolutely. OSHA fully permits digital and electronic SDS libraries, and frankly, they're often far more efficient than shelves of dusty binders. But switching to digital comes with a few non-negotiable conditions. The core principle of "ready accessibility" doesn't go away just because you’re using a screen instead of paper.

For a digital system to be compliant, it must meet these key tests:

- No Barriers to Access: Employees must be able to get to the SDSs immediately, right when they need them, during their work shift. This means they can't be forced to hunt down a supervisor for a password or get behind a locked door just to use the computer.

- Solid Training: You have to train every employee who might be exposed to hazardous chemicals on how to actually use the system. They need to know exactly how to log in, search for a chemical, and pull up the information they need, all on their own.

- A Reliable Backup Plan: This is critical. What happens if the power goes out or the network crashes? You must have a plan for how employees will access SDS information. This could be a designated laptop with a backup battery and a locally saved version of the library, but you need something.

An electronic system is only compliant if it works when you need it most—including during an emergency. A system that goes down with the power isn't a compliant system.

How Often Must Safety Data Sheets Be Updated?

The initial responsibility to update an SDS lies with the chemical manufacturer or importer. They are required to revise an SDS within three months of learning any "significant new information" about a chemical's hazards or the best ways to protect against them.

As an employer using the chemical, your duty is a bit different. You aren't expected to constantly search the internet for new versions of every SDS in your library. Instead, your obligation is to maintain the most current SDS you receive from your suppliers. When a vendor sends you an updated version, you simply need to replace the old one.

A great best practice is to periodically ask your main suppliers for their latest SDSs, maybe as part of an annual review. This proactive step helps keep your library from getting stale. Of course, using a management system that can flag old documents or automatically check for new versions makes this process a whole lot easier.

Navigating OSHA's complex requirements doesn't have to be a constant battle. NextSDS provides an all-in-one platform that takes the guesswork out of SDS management, from checking supplier documents to giving your team instant mobile access. Ensure your chemical safety programme is always compliant and ready for inspection by visiting https://nextsds.com.