At its core, OSHA's requirements for Safety Data Sheets are straightforward: employers must keep a complete, up-to-date SDS for every hazardous chemical they use. They also need to make sure employees can get to them without a hassle and, just as importantly, train them on how to actually read and understand the information. This isn't just about paperwork; it's the foundation of OSHA's Hazard Communication Standard (HCS), which is built on every worker's fundamental "right-to-know" about the risks they face on the job.

Understanding Why SDSs Are Your First Line of Defence

It’s easy to see a Safety Data Sheet (SDS) as just another compliance document to file away. But a better way to think of it is as a detailed user manual for a potentially dangerous chemical. Its whole purpose is to arm you with clear, consistent information about a substance’s hazards and tell you exactly what precautions to take for safe handling, storage, and emergency response.

This entire system is built on a simple but powerful idea established by OSHA's Hazard Communication Standard (HCS): you have a right to understand the risks of the chemicals you work with. The HCS is designed to ensure this critical information flows smoothly from the chemical manufacturers all the way down to the people on the front lines—the employees on the factory floor, in the lab, or at the construction site.

The Global Language of Chemical Safety

To cut through the confusion that used to come from different companies and countries having their own formats, OSHA aligned the HCS with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). You can think of the GHS as a universal translator for chemical safety. It created a standard, 16-section format that every SDS now follows, no matter where in the world it comes from.

This standardisation is a game-changer. It means that whether a chemical comes from Germany or Japan, the vital information you need is always in the same spot. For example, you will always find:

- First-Aid Measures in Section 4

- Fire-Fighting Measures in Section 5

- Personal Protective Equipment (PPE) recommendations in Section 8

In an emergency, this consistency is priceless. When every second counts, you don’t have time to hunt through a custom-made document. You can jump straight to the right section and find the life-saving instructions you need. You can learn more about the structure and importance of what is a Safety Data Sheet in our detailed guide.

Global Harmonisation and Regional Differences

While the GHS provides a common framework, local authorities often add their own spin. In the European Union, for instance, compliance is handled by the REACH Regulation, which makes all 16 sections of the SDS mandatory. This includes sections on ecological and transport information that OSHA considers optional. Suppliers in the EU also have the complex task of providing SDSs in the official language of every member state where they sell their products.

The core idea of the HCS is that informed workers are safer workers. An SDS isn't just for compliance; it's a practical tool designed to prevent injuries, illnesses, and incidents by arming employees with knowledge.

Ultimately, getting the 'why' behind the rules is the first step to building a genuine safety culture. It's not just about having the right documents on file. It's about making sure your team is fully equipped to use them, which includes investing in effective security awareness training that gives them the confidence to act on the information provided.

What OSHA Expects From You: Nailing Your Core Responsibilities

Think of your chemical safety programme less like a dusty rulebook and more like a living, breathing system. Getting it right isn't just about ticking boxes; it's about ensuring every moving part works together to keep your people safe. OSHA's Hazard Communication Standard (HCS) lays out five fundamental duties for every employer. These aren't just suggestions—they are your legal and moral obligations, forming the bedrock of a safe workplace.

Let's break down exactly what that means in practice.

Get a Handle on Your Chemicals: Create and Maintain an Inventory

You can't protect your team from hazards you don't know you have. That’s why everything starts with a thorough chemical inventory. This means creating a master list of every single hazardous substance on-site, from the big drums in the warehouse to the cleaning supplies under the sink.

This isn't a one-and-done job. Your inventory needs to be a dynamic document, updated the moment a new chemical arrives or an old one is retired. This list is the foundation for everything else you do.

Make Sure SDSs are Always Within Reach

For every chemical on your inventory list, you need a corresponding Safety Data Sheet. But just having them isn't enough. OSHA is crystal clear that SDSs must be readily accessible to your employees during their work shifts. This is one of the easiest citations to get because many companies get this wrong.

What does "readily accessible" actually mean? It means an employee can get their hands on an SDS in minutes, without barriers. They shouldn't have to track down a supervisor, ask for a key to a locked cabinet, or wait for someone to log into a computer. Think a dedicated terminal on the workshop floor or a tablet that opens directly to your digital SDS library.

If you’ve gone digital, you absolutely must have a backup plan. What happens if the power goes out or the internet is down? You still need to provide access, which means having an offline solution ready to go.

Put it in Writing: Your Hazard Communication Programme

Your written Hazard Communication Programme is your game plan. It’s the formal document that spells out precisely how your company complies with every part of the HCS. This can't be a generic template you downloaded online; it has to be tailored to your specific workplace, your chemicals, and your procedures.

At a minimum, your written plan must detail:

- How You Label Containers: A clear process for labelling all containers, which you can learn more about in our guide to GHS label requirements.

- Your SDS System: Where your SDSs are stored and the step-by-step process for employees to access them.

- Employee Training Plan: Who gets trained, on what topics, and how often.

- Your Chemical List: A reference to your complete, up-to-date chemical inventory.

- Protocols for Contractors: How you'll inform outside workers about the chemical hazards they might encounter on your site.

Train Your Team So They Know What to Do

An SDS is just a piece of paper (or a digital file) if your employees don’t understand what it’s telling them. OSHA mandates that you train your team on the hazardous chemicals they work with before they start the job, and again whenever a new hazard is introduced.

Good training is more than just handing someone a binder. It needs to be engaging and practical, covering the essentials like:

- The basics of the HCS standard itself.

- Where to find the written programme and the SDSs.

- How to spot a chemical leak or release in their work area.

- The specific health and physical risks of the chemicals they handle.

- Crucially, how to protect themselves using proper procedures and personal protective equipment (PPE).

Label Everything, No Exceptions

Finally, every container holding a hazardous chemical in your workplace must be clearly labelled. We’re talking about everything from 55-gallon drums down to the smallest spray bottle. The label is your first line of defence—an immediate, at-a-glance warning.

The label needs the product name and some combination of words, pictures, or symbols that quickly communicate the hazards. This simple step ensures that even without an SDS in hand, the most critical safety information is always front and centre.

Navigating the Mandatory 16-Section SDS Format

Think of a Safety Data Sheet (SDS) as a chemical's biography, told in 16 distinct chapters. This isn't just a suggestion; it's a globally recognised structure that OSHA requires. Each section reveals a critical piece of the puzzle: what the substance is, how it can harm you, and exactly what you need to do to handle it, store it, and respond in an emergency.

This universal format—the Globally Harmonized System (GHS)—is a game-changer. It means that whether you're looking at a data sheet for industrial-strength cleaner from a huge corporation or a specialised solvent from a small supplier, you'll find the information you need in the exact same place, every single time. Need to know what gloves to wear? Go straight to Section 8. Dealing with a spill? Section 6 has the playbook.

This consistency is about more than just ticking a compliance box. It removes the panic and guesswork when things go wrong, making the SDS a practical, life-saving tool that anyone can use effectively.

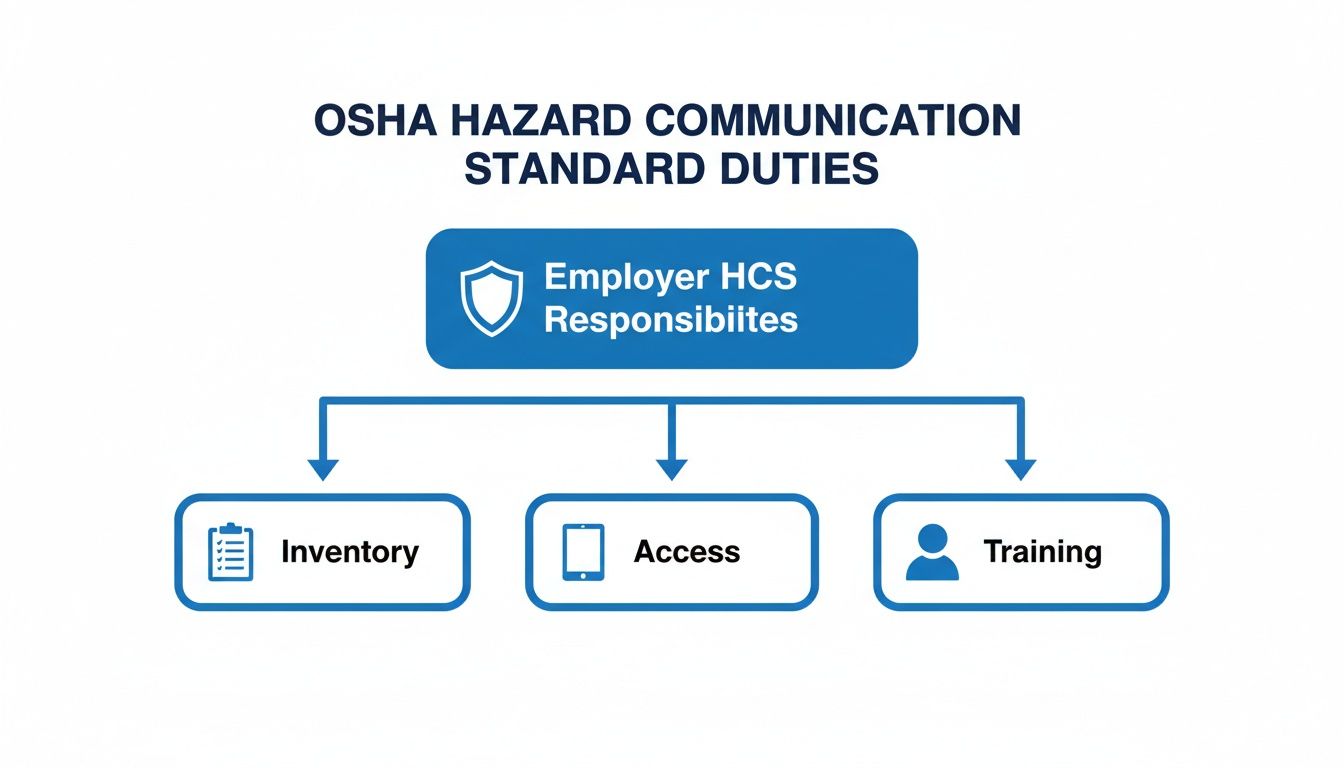

The flowchart below breaks down the core duties this system supports. It’s a simple visual reminder of your fundamental responsibilities: know what you have, make sure everyone can access the safety information, and train them on how to use it.

These three pillars—chemical inventory, easy SDS access, and proper training—are the foundation of OSHA’s Hazard Communication Standard. Everything else builds from here.

The Sections OSHA Actually Enforces

Here's something a lot of people miss: while a complete SDS has 16 sections, OSHA's direct enforcement only focuses on a specific subset. You are required to comply with the information in Sections 1 through 11 and Section 16.

The logic is straightforward: these sections contain the most critical, actionable information for protecting employees and first responders in a workplace setting. They cover identification, hazards, safe handling, and emergency response—the absolute need-to-know details.

So what about Sections 12 through 15? OSHA encourages manufacturers to include them, but they don't enforce them. That's because this information—covering ecological impact, disposal, and transport—typically falls under the jurisdiction of other agencies, like the Environmental Protection Agency (EPA) or the Department of Transportation (DOT).

A Breakdown of the 16 GHS Sections in an SDS

To really get a handle on OSHA requirements for SDS sheets, you need to know what’s inside each of the 16 sections. This table serves as a quick-reference guide, breaking down the purpose of each chapter in a chemical's story.

| Section Number | Section Title | Required Information |

|---|---|---|

| 1 | Identification | Product name, manufacturer/supplier contact details, recommended uses, and any usage restrictions. |

| 2 | Hazard(s) Identification | All hazards related to the chemical, including its GHS classification, signal word (e.g., Danger, Warning), and pictograms. |

| 3 | Composition/Information on Ingredients | A list of chemical ingredients, including CAS numbers and concentration ranges. This is also where trade secret claims are noted. |

| 4 | First-Aid Measures | Immediate, practical instructions for untrained responders on what to do in case of inhalation, skin/eye contact, or ingestion. |

| 5 | Fire-Fighting Measures | Guidance on how to fight a fire involving the chemical, including suitable extinguishers and specific hazards that could be created. |

| 6 | Accidental Release Measures | Emergency procedures for handling spills, leaks, or releases. It covers containment, cleanup, and necessary PPE. |

| 7 | Handling and Storage | Best practices for safe handling and storage, highlighting any incompatible materials to avoid. |

| 8 | Exposure Controls/Personal Protection | OSHA’s Permissible Exposure Limits (PELs), recommended engineering controls, and specific personal protective equipment (PPE). |

| 9 | Physical and Chemical Properties | The chemical’s vital statistics: appearance, odour, pH, flash point, flammability, etc. |

| 10 | Stability and Reactivity | Details on the chemical’s stability and any conditions that could lead to a hazardous reaction. |

| 11 | Toxicological Information | Crucial health data, including routes of exposure, symptoms of exposure, and measures of toxicity. |

| 12 | Ecological Information | Information on the chemical's environmental impact, like its effect on aquatic life. (Not enforced by OSHA) |

| 13 | Disposal Considerations | Guidance on how to dispose of the chemical and its container safely and in accordance with regulations. (Not enforced by OSHA) |

| 14 | Transport Information | Classification details needed for shipping and transporting the hazardous chemical. (Not enforced by OSHA) |

| 15 | Regulatory Information | Other safety, health, and environmental regulations specific to the product not covered elsewhere. (Not enforced by OSHA) |

| 16 | Other Information | Includes the date the SDS was prepared or last revised. It’s a catch-all for any other useful information. |

Mastering this structure is the key to effective hazard communication. When your team knows exactly where to look for information, the SDS transforms from a dusty compliance document into an active tool for daily safety.

Building an Effective SDS Management System

An SDS library that’s outdated or inaccessible isn't just a compliance headache—it’s a serious liability. If you're still relying on dusty binders tucked away on a shelf, it's time for an upgrade. A truly effective system isn’t about passive storage; it’s about giving your team dynamic, real-time access to the information they need to stay safe.

Sure, the old binder method seems simple, but its drawbacks are huge. They’re a nightmare to keep updated, impossible to access from anywhere but the office, and completely impractical in an emergency. Just imagine a worker needing urgent first-aid information while their supervisor frantically flips through hundreds of pages.

This is where a digital system really shines. An electronic library puts every single SDS in one central, searchable place. They become instantly available from any authorised device—whether it's a tablet on the workshop floor or a manager's phone on the go. This simple shift turns a passive archive into an active, life-saving tool.

Key Features of a Robust Digital System

Not all digital solutions are built the same, though. To genuinely meet OSHA requirements for SDS sheets and create a resilient safety programme, your system needs to do more than just store files. A shared drive full of PDFs just won't cut it.

A truly effective digital platform should deliver:

- Instant Accessibility: Your employees must be able to pull up an SDS in minutes, without needing to ask for permission or hunt down a supervisor. A system that’s buried under complex logins or hidden in a confusing network folder is not compliant. Period.

- A Solid Backup Plan: OSHA is crystal clear about this. If your main system depends on electricity or an internet connection, you must have a backup for when things go wrong. This could be anything from an offline version saved on a local device to a dedicated binder with printed SDSs for your most critical chemicals.

- Intuitive Employee Training: The most sophisticated system in the world is useless if your team doesn't know how to use it. Training needs to be practical, showing employees exactly how to find a chemical, navigate to specific sections, and use the backup system when needed.

Relying on an electronic system without a reliable backup is a common and costly compliance error. An inspector won't accept "the Wi-Fi is down" as an excuse when an employee can't access critical hazard information.

From Reactive to Proactive Management

The real magic of a modern SDS management system is how it automates the most tedious compliance work. Instead of you manually chasing suppliers for updated documents, a smart system can do it for you. This proactive approach turns compliance from a constant chore into a seamless process humming along in the background.

This is especially critical with today's tangle of international regulations. For example, after Brexit, the UK set up its own UK REACH and GB CLP regulations under the Health and Safety Executive (HSE). While they largely mirror EU rules, there are important differences. This can mean businesses suddenly need to manage three distinct SDS versions for their US, EU, and UK operations. In fact, HSE data shows that a staggering 18% of workplace chemical incidents are linked to poor SDS availability, proving just how high the stakes are.

An automated platform can flag these regional requirements, automatically request updated sheets from suppliers, and notify you when regulations change. Your SDS library evolves from a static pile of documents into an intelligent safety hub. You can learn more about how SDS management software can improve these workflows and strengthen your safety programme. By moving to a digital-first strategy, you're not just ticking a box for OSHA; you're building a more resilient, proactive safety culture that genuinely protects your people.

Avoiding Common and Costly Compliance Pitfalls

Knowing the rules is half the battle; actually putting them into practice day-in and day-out is where things get tricky. It's frustrating, but citations for the Hazard Communication Standard are incredibly common, and they usually spring from simple, preventable mistakes. These aren't just bits of paperwork going astray—they're real safety gaps that expose your team to risks and can lead to some hefty fines.

The smartest way to bulletproof your own programme is to learn from where others have stumbled. By getting ahead of these common issues, you can make sure your approach to OSHA requirements for SDS sheets is not just compliant on paper but genuinely works to keep people safe. Let’s take a look at the most frequent tripwires and, more importantly, how to avoid them.

Pitfall 1: The Incomplete or Ancient SDS Library

This is, without a doubt, the most frequent stumble. An inspector walks in, points to a random bottle on a shelf, and asks to see the SDS. If you can't find it, or the one you pull out is a pre-GHS relic from ten years ago, you're in hot water. This usually happens because of a breakdown in process—a new solvent gets delivered, and the crucial step of getting the SDS from the supplier is completely missed.

How to fix it: Build a rock-solid receiving procedure. The rule should be simple: no hazardous chemical comes through the door without its corresponding, up-to-date SDS. To keep things tight, run a quick audit every quarter. Just walk the floor, spot-check your chemical inventory, and make sure every single one has a matching sheet in your library. This catches gaps before they become violations.

Pitfall 2: Locking Away the Information

Having a perfect SDS library is pointless if your team can't actually get to it. We often see binders stored in a locked manager's office or digital files on a password-protected computer that the people on the floor can't access. That’s a clear violation of the "readily accessible" rule. An employee should never have to hunt someone down and ask for permission to see vital safety information.

How to fix it: Access needs to be immediate and without barriers. If you've gone digital, set up a few dedicated, unlocked computer terminals right on the workshop floor. For those still using physical binders, place them in central, well-known locations that everyone can get to. And remember, OSHA requires a backup plan for digital systems. You have to be able to access that info even if the power goes out.

An SDS that takes more than a few minutes to find might as well not exist during an emergency. The goal is to eliminate any delay between a worker needing information and getting it.

Pitfall 3: "One-and-Done" Training

It’s a classic mistake: a company runs a single HazCom training session for new hires and then ticks the box, never touching the subject again. But training isn't a one-time event. OSHA requires it whenever a new chemical hazard is introduced. On top of that, the training has to actually stick. It’s not enough for employees to just sit through a PowerPoint; they need to walk away knowing exactly how to read an SDS and use that information to protect themselves.

How to fix it: Weave hazard communication into your regular safety meetings. When a new product arrives on-site, hold a quick "toolbox talk" to go over its specific risks and safety measures. Make the training real. Instead of abstract examples, hand them an SDS for a chemical they use every single day and ask them to find the right PPE or the first-aid instructions. That’s how you make it practical and memorable.

How Automation Changes the SDS Compliance Game

Let's be honest: managing Safety Data Sheets manually is a never-ending game of catch-up. It's a constant cycle of chasing down updated documents, wrestling with paperwork, and reacting to regulatory changes. You're always one step behind. This is where automation completely flips the script. It takes a tedious, reactive chore and turns it into a proactive tool that makes your entire safety programme stronger.

Think about it. Instead of your team wasting hours trying to get the latest SDS from a supplier, an automated system handles it all. It can reach out for the new document, scan it the moment it arrives, and instantly flag any new hazards or changes to PPE requirements. This isn't just a time-saver; it’s about closing dangerous safety gaps before they can cause a problem.

From Static Files to Smart Safety

Modern SDS platforms are much more than just digital filing cabinets. They act as a central intelligence hub for your chemical inventory, constantly checking what you have on-site against regulatory lists from all over the world. This gives any forward-thinking EHS team a massive advantage.

Here’s what that looks like in practice:

- Proactive Regulatory Checks: Imagine a system that flags a new chemical you’re about to purchase because it contains a substance on a restricted list like REACH. It stops the problem before the container even arrives at your door.

- Instant Hazard Alerts: When a regulator updates an exposure limit for a chemical, the platform can immediately identify every single product in your inventory affected by that change. No more manual cross-referencing.

- On-the-Spot Safety Info: The best systems can pull the most critical information out of a dense, 16-section SDS and generate simple, easy-to-read safety cards. A worker can just scan a QR code on a container with their phone and get instant access to vital PPE, first aid, and spill information.

Automation turns SDS management from a static library of documents into a living, breathing system that actively watches for risks. It’s the difference between having a fire extinguisher on the wall and having a smoke detector that warns you long before the flames appear.

This move toward intelligent, automated systems is quickly becoming a necessity. For businesses looking to seriously improve their compliance efforts, exploring practical AI solutions for small businesses can be a real eye-opener. By taking over the repetitive, time-consuming tasks tied to OSHA requirements for SDS sheets, automation frees up your safety professionals to focus on what they do best: building a safer workplace and a stronger safety culture.

Got Questions About OSHA SDS Requirements? We've Got Answers.

It's one thing to know the rules, but applying them in the real world often brings up tricky questions. Let's tackle some of the most common queries that pop up when managing Safety Data Sheets.

How Often Do I Need to Update an SDS?

This is a big one. OSHA's rule is based on new information, not a calendar. A chemical manufacturer has three months to update an SDS once they learn something new and significant about a chemical's dangers.

Your job as an employer is more straightforward: you just need to make sure you have the most current version from your supplier. There's no set "expiry date," but it's a good habit to regularly check your SDS library. This is where an automated system really shines, as it can flag outdated sheets for you.

Are Digital SDS Libraries Okay with OSHA?

Absolutely. Digital and online SDS libraries are perfectly fine, but with one massive caveat: every single employee needs immediate access to them during their shift. There should be no barriers—no asking a supervisor, no waiting for a password.

You also need a solid backup plan. What happens if the power goes out or the internet dies? OSHA expects you to have an answer, whether it's a binder with printed copies for the most hazardous chemicals or an offline version saved on a local computer.

The bottom line is all about access. If a worker can't pull up an SDS in just a few minutes, your system isn't compliant, no matter how fancy it is. And don't forget, you have to train everyone on how to use both the digital system and its backup.

Do I Really Need an SDS for Windex?

This question comes up all the time, and the answer is: it depends on how you use it. If you're using a standard consumer product like a bottle of window cleaner in the same way you would at home, you don't need an SDS.

But the game changes the second your workplace use becomes more intense. Are your employees using massive, industrial-sized jugs of that same cleaner all day long? Is their exposure far greater than a typical consumer's? If so, the Hazard Communication Standard kicks in, and you absolutely need to have an SDS on file for it.

Ready to move from reactive compliance to proactive safety? NextSDS replaces outdated binders and spreadsheets with a smart, automated platform. Get instant access, real-time regulatory alerts, and peace of mind knowing your chemical safety is always under control. Discover how you can simplify your OSHA SDS requirements at https://nextsds.com.