At its core, safety data sheet authoring software is a purpose-built tool designed to create, manage, and share crucial chemical safety documents. Think of it as the central nervous system for your chemical compliance, replacing the old, creaky filing cabinets and spreadsheets with an intelligent, automated system. It’s an essential piece of kit for any business that handles hazardous materials in our increasingly complex and regulated world.

Why Manual SDS Management Is No Longer Viable

If you’ve ever found yourself staring at a wall of chemical binders or lost in a labyrinth of spreadsheets, you know the feeling. This old-school approach isn't just inefficient; it’s a huge liability in today's regulatory environment. The sheer volume of data, combined with constantly changing global rules, makes managing it all by hand a recipe for compliance headaches and, worse, safety incidents.

A High-Speed Market Analogy

Imagine trying to track stock market trades during a high-frequency trading surge with just a pen and paper. You’d miss critical price shifts, make costly calculation errors, and fall behind almost instantly. That's a perfect analogy for what happens when a business relies on manual methods for its Safety Data Sheet management.

The chemical industry moves with similar speed and complexity. New regulations pop up, substance classifications get updated, and supplier information changes without warning. A static spreadsheet or a dusty binder on a shelf simply can't keep up.

The Real-World Pain Points

Sticking with outdated systems creates very real, everyday problems that directly impact safety and efficiency. These aren't just minor administrative annoyances; they are significant business risks that modern safety data sheet authoring software is built to solve.

Here are a few of the biggest struggles with manual processes:

- A High Probability of Human Error: Manually typing in complex chemical data, like CAS numbers and hazard classifications, is a minefield of potential mistakes. One wrong digit or a misplaced decimal can lead to incorrect handling procedures and serious safety breaches.

- The Struggle to Keep Up with Regulatory Updates: Tracking changes to global regulations like REACH, CLP, and OSHA is practically a full-time job. Without an automated system to flag these changes, a company could be using non-compliant documents for months, leaving it wide open to fines and legal trouble.

- A Crippling Administrative Burden: The hours spent chasing down suppliers for new SDSs, updating internal records by hand, and then making sure every single employee has the latest version are immense. This administrative black hole pulls your skilled EHS team away from what they should be doing—proactive risk assessments and safety training.

The move away from these inefficient manual methods to a smart software solution is a textbook example of successful business process automation.

By ditching the reactive paperwork shuffle, organisations can build a proactive strategy for safety and operational excellence. This isn’t just a tech upgrade; it’s a fundamental shift in how chemical safety is woven into the very fabric of the business.

SDS Management A Shift From Manual Risk to Automated Strategy

The table below offers a quick comparison of the outdated manual process versus a modern, software-driven approach to chemical safety and compliance. It clearly shows the jump from a system riddled with risks to one built for resilience and efficiency.

| Manual Approach (Spreadsheets & Binders) | Automated Software Approach |

|---|---|

| Prone to human error, typos, and data omissions. | Data validation and automated checks minimise errors. |

| Regulatory updates are a manual, time-consuming task. | Real-time regulatory database updates and alerts. |

| Document distribution is slow and hard to track. | Instant, auditable distribution to all stakeholders. |

| Inconsistent formatting and language across documents. | Standardised templates ensure global compliance. |

| Version control is a nightmare, leading to outdated info. | Centralised system ensures everyone has the latest version. |

| Finding a specific SDS in an emergency is slow. | Immediate, searchable access to any document. |

Ultimately, the choice is between clinging to a process that invites risk and inefficiency or embracing a strategy that protects your people, your reputation, and your bottom line.

The Core Features That Modernise Chemical Safety

Forget thinking of modern safety data sheet authoring software as just a digital filing cabinet. It’s much more than that. Think of it as an intelligent, interconnected system that shifts chemical safety from a reactive chore to a proactive, data-driven strategy. These tools build a connected ecosystem where information flows seamlessly between departments, stopping errors in their tracks and ensuring compliance at every turn.

Let's get past a simple feature list and really dig into the high-impact capabilities that define these platforms. We'll break down how each function works in a real-world setting, turning abstract concepts into practical, everyday solutions that protect your teams and your business.

AI-Powered Data Extraction and Validation

Manually typing data from a dense, 16-section SDS is not just tedious—it’s a recipe for human error. A single misplaced decimal point or a mistyped CAS number can have serious safety and compliance consequences. This is where AI-powered data extraction completely changes the game.

When a new SDS arrives, the software uses artificial intelligence to scan the document and automatically pull out the critical information. It intelligently identifies and populates fields for things like:

- Chemical Identifiers: Such as CAS numbers, EC numbers, and product names.

- Hazard Classifications: Including GHS pictograms, signal words, and hazard statements.

- Supplier Details: Ensuring contact information is always accurate and easy to find.

- Revision Dates: Automatically flagging outdated documents for review.

For a lab manager, this means no more squinting at PDFs and painstakingly typing complex data. They can simply upload a new sheet, and in moments, the system has accurately catalogued the substance, verified its classifications, and made it available across the organisation. This doesn't just save a huge amount of time; it builds a reliable, error-free foundation for your entire chemical inventory.

The Digital Compliance Officer: Regulatory Screening

Imagine having a dedicated compliance officer on your team who works 24/7, tirelessly checking every chemical in your inventory against thousands of global regulations. That’s essentially the role of automated regulatory screening in modern safety data sheet authoring software.

This feature maintains a constantly updated database of international, national, and regional chemical rules. It continuously screens your inventory against critical lists like:

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe.

- TSCA (Toxic Substances Control Act) in the United States.

- SVHC (Substances of Very High Concern) candidate lists.

- Proposition 65 in California.

This automated vigilance turns compliance from a periodic, stressful audit into a continuous, background process. The system doesn’t just store data; it actively monitors your chemical footprint for regulatory risks.

Picture a procurement team about to order a new cleaning agent. Before the purchase order is even approved, the software can screen the agent’s ingredients. If a substance is on a restricted list, the system immediately alerts both the procurement and EHS teams, preventing a non-compliant—and potentially costly—purchase from ever happening.

Integrated GHS Label Printing on Demand

Compliance doesn’t stop with the SDS document itself; it extends to every single container in your facility. Inconsistent or non-compliant labels are a frequent cause of safety incidents and regulatory fines.

Integrated GHS/CLP label printing solves this problem by directly linking your verified SDS data to your labelling process. This ensures every label is perfectly aligned with the most current safety information. Warehouse staff can generate compliant labels on-demand for secondary containers, lab samples, or outgoing shipments, right when they need them.

These systems allow for customisation while maintaining compliance, letting you:

- Add company logos or internal product codes.

- Print in multiple languages for international shipping.

- Scale labels for different container sizes, from small vials to large drums.

This capability empowers your teams on the ground to maintain safety standards without having to be experts in GHS labelling regulations. It closes a critical gap in the chemical management lifecycle, ensuring the information on the SDS is accurately reflected on the physical container where it matters most. For more details on building a complete system, you can learn more about what to look for in SDS management software and how it fits into a broader safety strategy.

Staying Compliant in a World of Ever-Changing Rules

Trying to keep up with chemical safety regulations across different countries feels like navigating a maze that's constantly changing. One wrong turn can lead to fines, shipment delays, or worse. For any business that operates internationally, trying to manage this by hand is not just difficult—it's a recipe for failure. This is precisely where safety data sheet authoring software steps in, acting less like a tool and more like an expert guide.

Think of it as having a regulatory specialist on your team, one who speaks the language of every market you're in. The software doesn't just create a generic SDS; it crafts documents that are perfectly aligned with the specific legal demands of each region, taking the guesswork and immense risk out of global compliance.

Making Sense of Global Chemical Regulations

The Globally Harmonized System (GHS) was meant to create a universal standard, but the reality is a bit messier. How each country implements GHS can vary quite a bit, meaning an SDS that's perfect for one market might be non-compliant in another. Good authoring software is built to handle these differences without you having to become a global legal scholar.

Here are a few of the major regulatory hurdles the software helps you clear:

- REACH and CLP (Europe): The EU’s rules are some of the toughest in the world. REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and CLP (Classification, Labelling and Packaging) have incredibly detailed requirements. The software ensures your SDSs and labels tick every box.

- OSHA's Hazard Communication Standard (HCS) (USA): In the United States, OSHA sets the rules for workplace chemical safety. Authoring platforms guarantee your documents follow the specific HCS format and include all mandated information.

- Transport Regulations (ADR/IATA): Compliance doesn't stop at the warehouse door. When you ship dangerous goods, you have to follow strict transport rules like ADR (road) and IATA (air). The software integrates these labelling and documentation needs right into your process.

This built-in global intelligence is what keeps your products moving and prevents costly disruptions at the border. The software manages the fine print so your team can focus on what really matters: keeping people safe.

Turning Regulations into Real-World Actions

The real magic happens when the software transforms a dry legal update into an immediate, practical response. Let’s say a chemical you use is suddenly added to the Substance of Very High Concern (SVHC) list under REACH.

Without automation, you might not find out for weeks or months. With the right system, the change is flagged instantly. The substance is automatically quarantined in your digital inventory, and alerts go out to the people who need to know.

This proactive approach completely changes the game. Your Head of Procurement gets a notification, stopping them from ordering any more of the newly restricted substance. At the same time, the EHS Manager is prompted to assess the risk of its current use and start looking for a safer alternative. Compliance shifts from a reactive headache to a smooth, proactive process.

This automated vigilance is especially vital in highly regulated markets. For example, North America has become the world's leader in the SDS Authoring Software market, holding 38% of the global market share. This is largely because agencies like OSHA enforce strict, non-negotiable standards for SDS documentation. You can get more details on the global SDS software market on marketintelo.com.

By constantly scanning for updates and triggering the right actions, the system ensures your entire hazard communication programme is always in sync with the law. This drastically cuts down the risk of fines, shutdowns, and damage to your company's reputation. Ultimately, it gives you the confidence to operate anywhere in the world, knowing your compliance is under control. To dive deeper into this topic, take a look at our guide on achieving total Safety Data Sheet compliance.

How SDS Software Weaves into Your Daily Operations

Good safety data sheet software isn't some isolated tool that only the EHS department touches. Far from it. When implemented correctly, it becomes the central nervous system for chemical safety, plugging directly into the daily rhythms of multiple teams. It’s about turning complex safety regulations into practical, on-the-ground intelligence, right where it’s needed.

This integration dissolves the old silos between departments. Safety stops being a box-ticking exercise and becomes a core part of how everyone, from the lab to the loading bay, makes decisions. Everyone is working from the same, single source of truth.

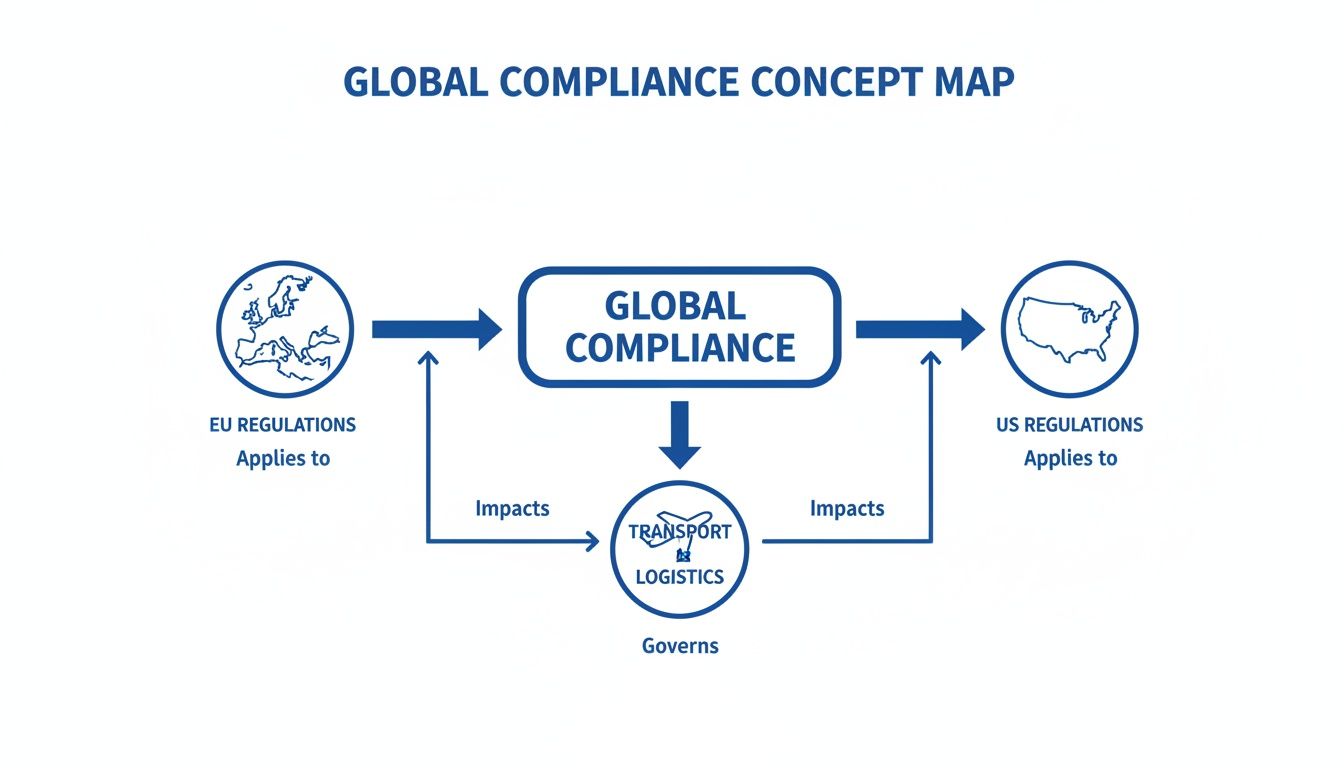

The map below gives you a sense of how these global compliance threads, all managed within the software, connect and influence different parts of the operation, like transport and logistics.

As you can see, a central system has to juggle very different regulatory worlds—like those in the EU and the US—to keep cross-border transport compliant. Let’s look at what this actually means for the people on the front line.

A Day in the Life: The HSE Manager

For any Health, Safety, and Environment (HSE) Manager, risk assessments are bread and butter. But they often involve a frustrating hunt for information scattered across different systems and binders. With integrated safety data sheet software, that entire process becomes data-driven and almost instantaneous.

Picture this: a new chemical arrives on the factory floor. Instead of digging through a filing cabinet, the manager pulls up its complete, AI-verified SDS profile in seconds. This gives them:

- Precise Occupational Exposure Limits (OELs) to guide air quality monitoring.

- The exact Personal Protective Equipment (PPE) needed for safe handling.

- Crucial storage compatibility data to prevent dangerous chemical reactions.

They’re no longer working with potentially outdated paper copies. They’re using real-time, validated information to assess exposure risks and put controls in place immediately. It shifts risk management from a reactive, time-consuming chore to a proactive, precise function.

Smarter Decisions for the Procurement Team

Think of your procurement team as the first line of defence against non-compliant chemicals. Without the right systems, a buyer could easily—and unknowingly—purchase a substance that’s restricted or even banned. That mistake can lead to costly returns, project delays, and hefty regulatory fines.

An integrated SDS platform acts as a smart gatekeeper. It builds compliance checks right into the purchasing workflow, stopping problems before they even start.

Here’s a common scenario. A team member requests a new solvent. Before that purchase order can be approved, the chemical’s CAS number is checked against the system. The software automatically screens it against global watch lists, like the REACH SVHC list. If a red flag pops up, the system alerts both procurement and HSE, effectively blocking a non-compliant purchase.

This simple check saves an incredible amount of time, money, and regulatory headaches down the line. Procurement is no longer just a transactional department; it becomes a strategic partner in corporate responsibility.

Empowering Staff in the Lab and Warehouse

For the people working hands-on with chemicals every day, quick access to safety information isn't just about compliance—it's about their personal well-being. A central platform puts this critical data directly into their hands, right at the point of use.

A Lab Manager, for instance, can quickly find the proper handling procedures and emergency first-aid measures for any substance in their inventory. It ensures every experiment is set up safely and the team is ready to respond to any accidental spill or exposure.

Over in the warehouse, a staff member can use a phone or tablet to scan a QR code on a drum. In an instant, a simple, mobile-friendly safety card appears with the essentials:

- Clear GHS pictograms for at-a-glance hazard recognition.

- Required PPE, like specific gloves or eye protection.

- Simple instructions for safe handling and storage.

This on-demand access empowers every employee, no matter their role, to make safer choices. The vital information buried in a 16-section SDS isn't locked away in an office anymore—it's out on the floor, actively protecting your people.

Choosing and Implementing Your SDS Solution

Picking and rolling out a new safety data sheet authoring software is a big move, but it doesn’t have to be overwhelming. The secret is having a solid plan that covers both how you’ll choose the right tool and how you’ll get it up and running. If you focus on the right criteria and follow a clear path, you’ll find the transition is much smoother, and you'll start seeing the benefits almost immediately.

Think of it like building a house. You wouldn’t just start laying bricks without a detailed blueprint. In the same way, you need a blueprint for adopting new software. This plan should map out your needs, the steps for moving your data over, and how you’ll get your team comfortable with the new system. A little strategic planning up front prevents a lot of headaches down the road and makes sure the system actually fits your company's safety and compliance goals.

The Essential Evaluation Checklist

Let's be honest, not all SDS platforms are created equal. To find the one that’s right for you, you have to look past the sales pitches and really measure it against what your teams do every day. A proper evaluation will help you choose software that can grow with your business and deliver real value for years to come.

Use this checklist as your guide when you’re comparing options:

- Comprehensive Regulatory Coverage: Does the platform speak the language of every region you do business in? Make sure it has built-in, constantly updated support for all the big ones, like REACH, CLP, OSHA, and WHMIS.

- Scalability and Performance: The system needs to handle your chemical inventory today and be ready for whatever you throw at it tomorrow. Ask vendors how it handles bulk uploads and what its performance is like with thousands of documents.

- Intuitive User Interface (UI): If a system is clunky and complicated, your team simply won't use it. The software should feel natural to everyone, from the HSE manager doing a deep-dive risk assessment to a warehouse team member needing to pull up a safety card on their phone.

- Robust AI Capabilities: Put its AI to the test. How accurately does it actually pull data from supplier SDSs? Crucially, does it then cross-reference that information against official regulatory lists to flag potential issues?

- Vendor Support and Training: A great piece of software is only half the equation; the team behind it is the other half. Look into the vendor’s reputation for support, what their onboarding process looks like, and the quality of their training resources.

Your Roadmap to a Successful Implementation

Once you’ve made your choice, the real work begins: implementation. A well-planned rollout is what separates a system that gets used from one that collects digital dust. For most organisations, a phased approach is the best way to keep things manageable and smooth.

A successful implementation isn't just about the tech; it's about your people and your processes. Clear communication and training that’s tailored to different roles are the cornerstones of getting everyone to embrace the new system.

Here’s a step-by-step roadmap to guide you through the process:

- Migrate from Legacy Systems: First things first, get your data out of the old system. Most modern platforms let you bulk-upload your existing SDSs. Work with your new vendor to ensure a clean transfer from those old spreadsheets, binders, or outdated software into your new, centralised library.

- Validate Existing Documents: This is where you get an instant win. As your SDSs are uploaded, use the software’s built-in validation tools to give them a health check. The system can automatically flag documents that are out of date, missing key information, or aren't compliant with current GHS standards.

- Design Effective Training Programmes: A one-size-fits-all training video won’t cut it. Your procurement team needs to understand the pre-purchase screening workflow. Meanwhile, your warehouse staff need to know how to quickly access mobile safety cards and print GHS-compliant labels. Tailor the training to the job.

- Execute a Phased Rollout: Don't try to go live for everyone at once. Start with a pilot group or a single department. This gives you a chance to gather real-world feedback and iron out any kinks on a smaller scale before launching it across the entire organisation. Keep everyone in the loop throughout this process to manage expectations.

By following a structured approach like this, you can move to a powerful new system that doesn’t just tick compliance boxes but truly embeds safety into your day-to-day operations. For a deeper look into the components of a robust system, check out our guide on what to look for in a safety data sheet management system.

Measuring the Payback from Automated Compliance

Sooner or later, any conversation about new technology lands on one crucial question: what’s the return on investment? When it comes to safety data sheet authoring software, the answer isn’t just about dodging fines. It’s a powerful mix of hard cash savings and strategic gains that make the whole organisation stronger and smarter.

Think about the most obvious win first: getting your people’s time back. Manually wrangling SDS documents—finding them, updating them, sending them out—burns through hundreds of hours a year. A platform like NextSDS takes that administrative grind off your plate, freeing up skilled HSE professionals to do what they do best, like running risk assessments and training sessions, not drowning in paperwork.

Putting a Number on the Financial Returns

Beyond saving time, the financial payback becomes crystal clear when you start tracking the right things. Automation directly stops expensive mistakes in their tracks and helps you manage resources more effectively, leading to savings you can actually see on the balance sheet.

Here’s where the money is saved:

- Drastically Lower Risk of Fines: Getting it wrong with regulations like REACH or OSHA can lead to penalties hitting tens of thousands of pounds for a single mistake. Automation is your best defence against these compliance slip-ups.

- Stopping Bad Purchases Before They Happen: The software can screen chemicals before your team even places an order. This prevents the costly headache of buying a restricted substance, saving you on return shipping and avoiding project delays.

- Smarter Chemical Inventory: When you have one central, accurate view of every chemical you hold, you stop over-ordering. This cuts down on the cost of storing and, eventually, disposing of materials you never needed in the first place.

Investing in automated compliance isn’t just another expense. It’s a strategic decision that turns a potential cost centre into a hub of efficiency and risk management. The financial upside is so much bigger than just avoiding penalties.

The Strategic Value of a Rock-Solid Safety Culture

The payback from safety data sheet authoring software isn't all about pounds and pence. The strategic value it delivers can be even more profound over time, boosting your company's reputation and making your entire operation more resilient.

This isn’t just a fuzzy, feel-good benefit; it’s built on solid foundations. First, you get a huge efficiency boost. Information silos get torn down, and everyone—from procurement to the lab and the warehouse—starts working from the same playbook. That alone smooths out countless operational wrinkles.

Second, it builds a genuinely stronger safety culture. When every employee can instantly get their hands on clear, correct safety information, they’re empowered to work safer. Workplace incidents naturally go down.

Finally, it sends a powerful message. Being proactive about safety and compliance shows customers, regulators, and even future employees that you’re a serious, responsible organisation. That's not just good practice; it's just plain good business.

Got Questions? We've Got Answers

Thinking about moving to a modern chemical safety platform? It's a big step, and you probably have a few questions. Let's tackle some of the most common ones we hear about safety data sheet authoring software.

Can the software really handle regulations for different countries?

Absolutely. In fact, this is one of its most powerful features. These platforms are built on massive, constantly updated databases that cover global regulations, from REACH and CLP in Europe to OSHA in the United States.

When you create a document, the software automatically pulls the right rules and formats your safety data sheets and labels for that specific country. It means you can be confident your documentation is compliant, whether you're shipping a product to Berlin or Boston.

How does the software keep up with all the regulatory changes?

Keeping track of global chemical regulations is a full-time job, and that's precisely what the software provider does for you. Reputable platforms have teams dedicated to monitoring regulatory shifts around the world.

Updates are pushed to the cloud-based system automatically and often in real-time. When a new rule appears or a substance gets added to a restricted list (like the SVHC list), the system's database is updated. This can even trigger alerts, re-screening your entire chemical inventory to flag any products that are suddenly non-compliant.

The real magic of safety data sheet authoring software is how it turns compliance from a stressful, manual checklist into a quiet, automated background process. It becomes a vigilant watchdog for your chemical inventory, so you don't have to be.

How painful is it to move all our existing documents into a new system?

This is a common concern, but modern systems are designed to make this as painless as possible. Most platforms let you bulk upload your existing PDFs. From there, clever AI tools get to work, scanning each document and pulling out all the crucial data to build your new digital library.

Many even have features like a dedicated email inbox that can automatically process new SDSs as they arrive from your suppliers. While any migration needs a bit of planning, the goal is to let the technology do the heavy lifting, saving you from days of manual data entry.

Ready to see how NextSDS can automate your compliance and build a stronger safety culture? Explore our platform and book a demo to see these features in action. Visit https://nextsds.com to learn more.