A safety data sheet management system is a purpose-built software tool that takes the headache out of handling chemical safety information. Forget the old days of dusty binders and unwieldy spreadsheets. This is your command center for collecting, storing, checking, and sharing critical data on hazardous materials.

The whole point is to give everyone in your organization—from the loading dock to the lab—instant access to the most up-to-date safety info. It's about keeping people safe and staying on the right side of the law.

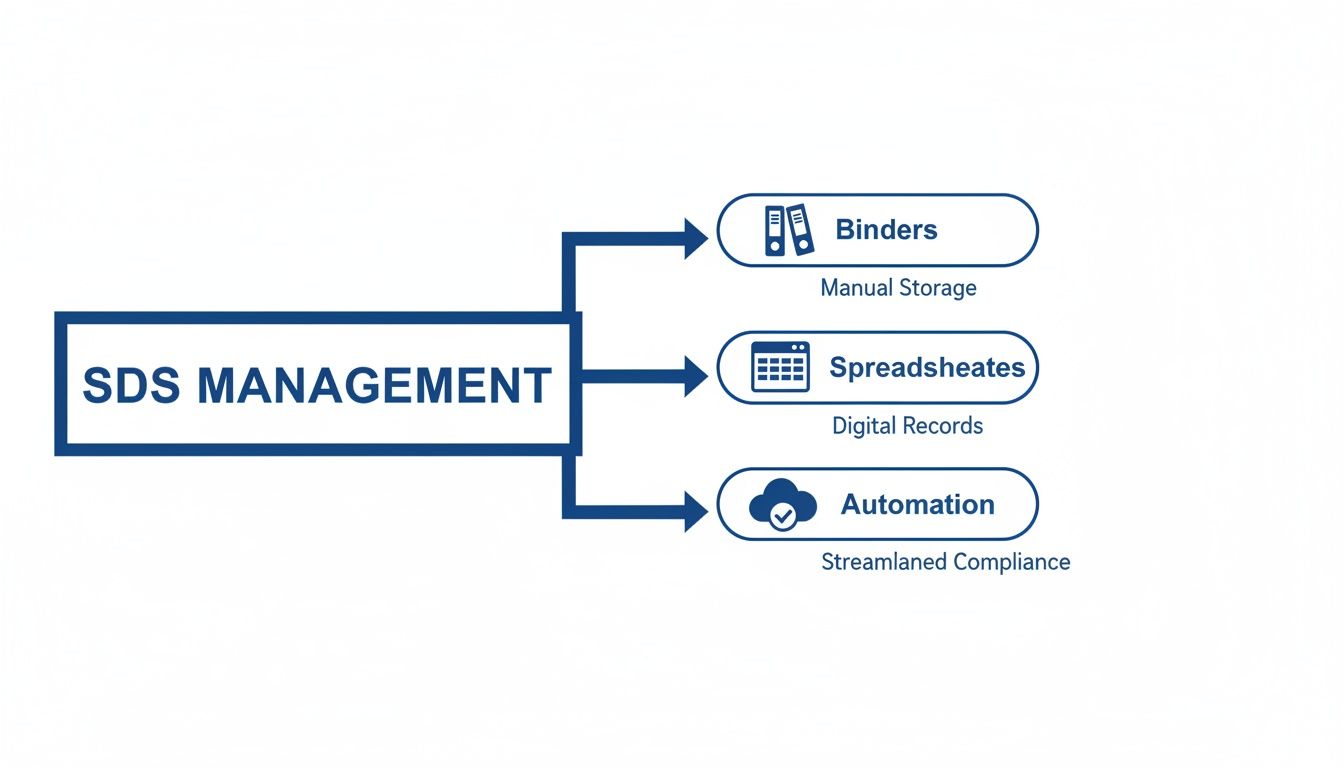

From Binders and Spreadsheets to Smart Automation

For years, Environment, Health, and Safety (EHS) managers were stuck in a paper-based world. Every new chemical meant printing out another Safety Data Sheet (SDS), punching holes in it, and cramming it into a packed three-ring binder. Then, they’d have to manually log it in a spreadsheet. It was a slow, painful process just begging for errors.

This old way of doing things is a huge operational drag. Imagine the chaos of trying to find the right SDS in an emergency, flipping through hundreds of pages while the clock is ticking. For companies with a lot of chemicals, just making sure every single sheet is the latest version from the supplier is a full-time job in itself. It’s a reactive system that only shows its cracks when something goes wrong.

The Shift to Proactive Safety Management

A modern safety data sheet management system completely flips the script. It moves you from a reactive, paper-chasing mode to a proactive safety strategy. The core problem it solves is information chaos. By creating a single, reliable source for all your chemical data, it becomes an active partner in your safety program, not just a digital filing cabinet.

This leap from manual tracking to a smart platform is really about applying the principles of modern knowledge management systems to make complex data easy to find and use. The software pulls in, organizes, and even analyzes your chemical library, offering a level of control that was impossible with paper.

Here’s what that looks like in the real world:

- Instant Accessibility: An employee can scan a QR code on a chemical container with their phone and immediately pull up the safety data they need. No more hunting for a binder.

- Automated Updates: The system keeps an eye on your suppliers and automatically fetches the latest SDS versions. You can be confident your information is never out of date.

- Compliance Assurance: It constantly checks your chemical inventory against global regulatory lists, flagging any restricted substances before they become a costly problem.

- Reduced Administrative Burden: All that automation frees up your EHS team from mind-numbing clerical work. They can finally focus on what matters—like improving safety training and performing risk assessments.

By digitizing and automating this critical function, businesses move beyond simply storing documents. They create a dynamic safety ecosystem where information is always current, accessible, and actionable, turning compliance from a burden into a competitive advantage.

Core Features That Drive Modern Chemical Safety

Let’s be clear: a real safety data sheet management system isn't just a digital filing cabinet. It’s an active, intelligent ecosystem built to automate compliance and genuinely reduce risk. These platforms are packed with specific, powerful features that work in concert to create a safety framework that actually works. They turn static PDFs into dynamic, actionable intelligence that protects your people and your business.

Think of it as a central command center for chemical safety. No more hunting down documents from different departments, suppliers, or forgotten binders. Every employee gets a single source of truth, which is critical for eliminating the dangerous guesswork that comes from using outdated or missing information.

This image perfectly illustrates the journey from outdated, manual methods to the streamlined, automated systems we have today.

The progression from dusty binders to smart automation really drives home the core benefit: a massive drop in manual busywork and a huge boost in accuracy and accessibility.

Automated SDS Acquisition And Ingestion

Anyone who has managed SDSs manually knows the biggest time-sink is just getting the documents in the first place. A key feature of a modern system is its ability to grab and process SDSs with almost no human touch. This isn't just about uploading a PDF; it's about smart procurement.

For example, many systems offer a "Magic Mailbox" where you can simply forward an email from a supplier. The platform automatically finds the attached SDS, files it, and starts pulling the data out. The really advanced platforms even have an AI agent that can proactively bug suppliers for updated sheets or scan the web for the latest versions, making sure your library is never out of date.

AI-Powered Data Parsing And Centralization

Once an SDS is in the system, its true power comes from unlocking the data inside. Manually typing out CAS numbers, hazard codes, and PPE requirements is not only slow but also a recipe for human error. This is where AI-powered parsing completely changes the game.

Using optical character recognition (OCR) and natural language processing (NLP), the system literally "reads" the document, regardless of its layout or format. It intelligently identifies and extracts dozens of crucial data points, including:

- Product Identifiers: Chemical names, CAS numbers, and EC numbers.

- Hazard Information: GHS pictograms, hazard statements (H-statements), and precautionary statements (P-statements).

- Exposure Controls: Permissible Exposure Limits (PELs) and Personal Protective Equipment (PPE) recommendations.

- Revision Dates: Absolutely vital for ensuring you have the most current version.

All this structured data then flows into a centralized, searchable digital library. Suddenly, you're not just searching for a document by its name. You can instantly find all products containing a specific ingredient or every chemical that requires respiratory protection. This level of granular control is foundational to improving chemical safety in the workplace.

To see the difference in a practical way, let's compare the old way of doing things with an automated system.

Manual SDS Management vs Automated System

The table below breaks down the day-to-day reality of managing chemical safety with outdated methods versus a dedicated system. The contrast in efficiency and risk is stark.

| Task | Manual Method (Spreadsheets & Binders) | Automated System (e.g., NextSDS) |

|---|---|---|

| Updating SDSs | Manually tracking revision dates; chasing suppliers for new versions. A constant, never-ending task. | Proactively flags outdated SDSs; AI agent automatically requests and ingests new versions from suppliers. |

| Data Extraction | Someone has to manually read and type data from each section into a spreadsheet. Extremely slow and error-prone. | AI instantly parses dozens of data points (CAS numbers, hazards, PPE) with high accuracy, creating a searchable database. |

| Regulatory Checks | Periodically cross-referencing chemicals against regulatory lists by hand. Easy to miss critical updates. | Continuously screens entire inventory against global lists (REACH, TSCA, Prop 65); sends immediate alerts for new risks. |

| Labeling | Creating labels manually, often with inconsistencies in pictograms or hazard statements. Risk of non-compliance. | Generates compliant GHS secondary labels on-demand directly from SDS data, ensuring 100% accuracy. |

| Employee Access | Workers must find a specific binder or log into a shared drive to find information. Impractical in an emergency. | Instant access on any device via QR codes; provides simplified "safety cards" with critical info at a glance. |

| Risk Assessment | A complex, data-intensive project requiring consolidation of multiple spreadsheets and documents. | Centralized data makes it easy to analyze chemical hazards, assess exposure risks, and generate reports in minutes. |

This side-by-side comparison makes it clear that relying on manual methods in today's regulatory environment isn't just inefficient—it's a significant liability.

Regulatory Screening And Proactive Alerts

Compliance isn't something you check off a list once a year; it’s a moving target. A robust safety data sheet management system automates this by constantly screening every chemical in your inventory against a huge database of global and regional regulatory lists.

The system acts as a vigilant watchdog, constantly cross-referencing your chemicals with lists like REACH, CLP, OSHA, TSCA, and Proposition 65. If a substance you use is added to a restricted list, you receive an immediate alert.

This incredible feature allows your procurement team to vet chemicals before they are even purchased, stopping non-compliant materials from ever setting foot in your facility. It flips the script from reactive, stressful compliance to proactive, strategic risk management.

On-Demand GHS Labeling And Mobile Access

Consistent, correct labeling is the bedrock of GHS and OSHA HazCom standards. An integrated labeling feature lets you print compliant secondary container labels directly from the system's SDS data. This guarantees every label has the right pictograms, signal words, and hazard statements, stamping out dangerous inconsistencies for good.

Even better, modern systems push this critical information right to the factory floor through mobile access. By generating QR codes for containers or work areas, employees can scan them with a phone or tablet and instantly pull up a simplified "safety card." This mobile-friendly summary gives them what they need to know at a glance:

- Key Hazards: Clear, color-coded warnings and pictograms.

- Required PPE: Simple icons showing exactly what gear to wear.

- First-Aid Measures: Immediate instructions if something goes wrong.

- Spill Response: The essential steps for containing an accidental release.

This immediate access empowers your team to make safer decisions in the moment, right where the chemicals are being used. It finally closes that critical gap between the central data library and the actual point of risk.

Navigating the Global Compliance Landscape

Handling chemical safety isn't just about doing the right thing for your employees; it's a legal requirement wrapped in a complex web of global and national regulations. Think of these rules as a universal language for chemical safety. A modern safety data sheet management system is your expert translator, making sure you speak that language fluently and avoid the steep penalties that come with getting it wrong.

These regulations aren't just one-and-done suggestions, either. They're constantly being updated to reflect new scientific findings. Trying to keep up manually is like trying to navigate a maze that changes its layout every single day. That's where smart automation stops being a luxury and becomes essential for managing risk.

The Foundation of Modern Hazard Communication

The bedrock of global chemical safety is the Globally Harmonized System (GHS) of Classification and Labelling of Chemicals. GHS isn't a law itself, but rather a universal framework that countries adopt to create consistency. It’s the reason a safety data sheet from Germany looks almost identical to one from Japan—they both use the same pictograms and follow the same 16-section format.

Here in the United States, the Occupational Safety and Health Administration (OSHA) folded GHS into its Hazard Communication Standard (HCS). This alignment created several non-negotiable legal duties for U.S. employers:

- You must maintain a current SDS for every single hazardous chemical on-site.

- Every SDS has to follow the standardized 16-section format.

- These documents must be readily accessible to employees during their work shifts. No exceptions.

- Any secondary containers you use have to be properly labeled with GHS-compliant information.

A dedicated management system is built to tackle these mandates head-on. Its central library gives every employee instant access, while its on-demand labeling feature ensures every container, from a massive tote to a small spray bottle, meets OSHA’s strict rules.

European Regulations REACH and CLP

Over in the European Union, two major regulations set the standard: REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and CLP (Classification, Labelling and Packaging). REACH is all about the production and use of chemicals, placing the responsibility squarely on companies to prove their chemicals are safe.

The CLP regulation works much like OSHA's HCS, implementing the GHS framework across the EU. It ensures hazards are clearly communicated to workers and consumers through standardized classification and labeling.

One of the most powerful features of a safety data sheet management system is its automated regulatory screening. The software is constantly checking your entire chemical inventory against lists of substances restricted or regulated under REACH and CLP, giving you an immediate heads-up if a chemical's status changes.

This proactive monitoring transforms compliance from a stressful, periodic fire drill into a smooth, ongoing process. It helps you spot and phase out problematic substances long before they could lead to fines or supply chain headaches, which is all part of maintaining solid safety data sheet compliance everywhere you operate.

Connecting System Features to Compliance Demands

The real value of a safety data sheet management system is how its features directly solve the compliance headaches you face in the real world. It’s not just about storing PDFs in a digital folder; it's about creating an active, auditable compliance engine that shields your business from legal and financial trouble.

Here's how specific tools map directly to regulatory requirements:

- Automated Audit Trails: When an OSHA inspector asks for proof of when an SDS was received, reviewed, or updated, you need an answer. An automated system keeps a detailed, time-stamped log of every single action, giving you irrefutable documentation on demand.

- Supplier Validation: The system can automatically screen incoming SDSs to confirm they are complete and follow the 16-section GHS format. This flags bad documents from suppliers before they ever make it into your library.

- Version Control: Regulations demand you use the most current SDS. The system automatically archives old versions and makes sure only the latest, supplier-verified document is in circulation, eliminating the dangerous risk of someone using outdated safety information.

In the end, these systems turn abstract legal jargon into simple, automated workflows. By building compliance right into your daily operations, you can finally shift your team's focus from chasing paperwork to actively making the workplace safer.

Beyond Compliance with Advanced Risk Management

A modern safety data sheet management system is so much more than a digital filing cabinet. It’s a command center for your entire chemical safety program, helping you get ahead of risks instead of just reacting to them. Checking compliance boxes is the starting line, not the finish line. Today’s platforms give you the tools to build a genuinely proactive safety culture.

How? By bridging the gap between the hazard data on an SDS and what’s actually happening on your shop floor. These systems link chemical information directly to your physical inventory, storage locations, and the specific tasks your employees perform. Suddenly, you have a complete, real-time picture of your risk profile, allowing you to stop problems before they start.

From Hazard Data to Actionable Risk Assessments

One of the biggest leaps forward is the integrated risk assessment module. An SDS tells you a chemical is hazardous, but a risk assessment tells you how dangerous it is in your specific context. The software takes the clean, structured data it pulled from your SDS library and does the heavy lifting for you.

Think about it this way: the system can calculate real-world exposure scores by weighing variables like:

- The chemical's inherent toxicity (straight from the SDS).

- The exact quantity being used in a process.

- How long and how often an employee is exposed.

- The effectiveness of your existing controls, like ventilation systems.

This data-first approach takes the guesswork out of safety. It gives you a consistent way to prioritize where you need to make improvements. It also helps you track and manage critical Occupational Exposure Limits (OELs), like Time-Weighted Averages (TWA) and Short-Term Exposure Limits (STEL), to ensure your team stays well within safe operating boundaries.

Intelligent Chemical Inventory and Storage Management

Another game-changing feature is connecting your SDS library directly to your physical chemical inventory. This creates a live, dynamic map of every hazardous substance in your facility—where it is, how much you have, and what’s sitting next to it. It’s like giving your chemical storage areas a brain.

This integration unlocks a few crucial safety functions:

- Storage Compatibility Checks: The system uses chemical segregation logic to automatically flag dangerous combinations. For example, it’ll warn you if someone tries to store flammable liquids too close to oxidizers, preventing a potentially catastrophic reaction.

- Quantity Threshold Alerts: It monitors your chemical volumes and compares them to regulatory limits (like the EPA's SARA Title III), sending an alert when you're getting close to a reporting trigger.

- Compliant Waste Disposal: Based on the SDS data, the system provides clear instructions for proper waste segregation and disposal, which helps you avoid environmental contamination and hefty fines.

This intelligent inventory management moves safety from a binder in an office to the warehouse floor. It provides actionable, location-specific guidance that helps workers make safer storage and handling decisions every single day.

The Growing Market for Proactive Safety

The rapid adoption of these advanced features isn’t happening in a vacuum; it’s part of a huge industry shift. The global market for SDS management has exploded, rocketing from $456.3 million in 2019 to an estimated $2.7 billion by 2024. This growth shows just how seriously organizations are taking proactive safety, choosing automated solutions over old-school manual methods.

A recent National Safety Council survey drives this point home, revealing that 77% of companies using these systems directly credit them for improving employee safety outcomes. You can read the full research on the expanding role of SDS management platforms to see why this market just keeps growing.

By directly tying safety data to physical inventory and daily work practices, a modern safety data sheet management system becomes an essential tool for operational excellence. It allows you to spot, analyze, and control hazards with a level of precision and speed that was simply impossible before, turning your safety program from a reactive chore into a predictive, strategic advantage.

Choosing and Implementing the Right SDS System

Picking and rolling out a new safety data sheet management system isn’t just an IT project; it’s a major move that directly affects your company’s safety, compliance, and day-to-day operations. Leaving behind old binders or clunky spreadsheets requires a solid game plan, from choosing the right software partner to getting everyone on board. The real goal is to find a system that solves your problems today and can adapt as your business grows.

A smooth transition hinges on finding a platform that actually fits how your team works. You need to be realistic about your team's tech-savviness, the sheer volume and complexity of your chemical inventory, and whether the new system can talk to the other software you already rely on. A well-planned rollout means you start seeing the benefits immediately, making the system a cornerstone of your safety culture instead of just another login to remember.

Key Criteria for Selecting Your System

Let's be clear: not all SDS platforms are built the same. To find the one that's right for you, you have to dig deeper than a simple feature checklist. The key is to evaluate how the software will actually perform in your world. A thorough evaluation now will save you from a huge case of buyer's remorse later.

Here’s what you should be looking for:

- Scalability: Can this system keep up as you grow? A platform that’s great for 100 chemicals needs to be just as fast and effective when you hit 10,000. Make sure the performance—and the price—won't become a roadblock down the line.

- Ease of Use: If your team finds the system confusing, they simply won't use it. Look for a clean, intuitive interface, easy mobile access, and straightforward dashboards. Everyone, from the EHS manager to the operator on the floor, should be able to find what they need in seconds.

- Integration Capabilities: A system that operates in a vacuum is a recipe for data headaches. The best platforms connect seamlessly with your existing Enterprise Resource Planning (ERP) or procurement software, creating a single source of truth. This is a foundational concept in modern enterprise content management solutions, where interconnected systems are non-negotiable.

The right system should feel like a natural extension of your team, not another piece of software to manage. Focus on how it will simplify workflows, automate tedious tasks, and provide clear, actionable insights that make everyone's job easier and safer.

A Roadmap for Successful Implementation

Once you’ve picked your system, the real work begins. A step-by-step approach is crucial here to dodge common traps and ensure a transition that adds value from day one. If you rush this part, you'll likely end up with bad data and a team that doesn’t want to use the new tool.

Follow these proven steps for a rollout that sticks:

- Data Migration and Cleanup: This is ground zero and arguably the most important step. Start by gathering every single SDS you have—from digital folders, binders, and supplier emails. Work with your provider to get this library into the new system, but just as importantly, use this as a chance to throw out outdated documents and plug any gaps. So many projects get bogged down because this initial cleanup was underestimated.

- System Configuration and Workflow Setup: Now, you tailor the platform to your company's reality. This means setting up user roles and permissions (who can see and do what), defining what triggers an alert for regulatory updates, and building out the approval process for bringing new chemicals onsite.

- Team Training and Buy-In: A system is only as good as the people who use it. You absolutely need to run training sessions that are specific to different roles. But more than that, you need to earn their buy-in. Show your departments exactly how this new safety data sheet management system makes their jobs less frustrating and, ultimately, safer.

By following this roadmap, you can make sure your new platform is not just installed, but truly woven into the fabric of your organization. For a deeper look into the features that can streamline this process, explore our comprehensive guide on SDS management software.

The Future of Chemical Safety Is Proactive

Moving on from dusty binders and cumbersome spreadsheets isn't just an upgrade—it's a complete reimagining of workplace safety. A modern safety data sheet management system is so much more than a digital filing cabinet. Think of it as the central nervous system for a proactive, data-driven safety culture that protects your people and your bottom line. It's the difference between hoping you're compliant and knowing you are.

These platforms bring everything into one place, creating a single source of truth for your entire organization's chemical data. By automating the mind-numbing (but critical) tasks like chasing supplier updates and cross-referencing regulatory lists, they give your EHS team their time back. Instead of drowning in paperwork, they can focus on what really matters: preventing incidents before they happen.

Build a Smarter and Safer Workplace

A purpose-built platform doesn't just store information; it gives you the insights you need to spot, assess, and control chemical risks before they turn into something serious. It’s about connecting the dots between hazard data, your physical inventory, and your day-to-day operations to create a complete safety picture.

Trying to manage complex chemical risk with a simple spreadsheet is like trying to navigate a maze with a blindfold on. The future of workplace safety belongs to those who use technology to make smart, data-informed decisions that keep their teams safe and their operations running smoothly.

It’s time to leave the limitations of manual processes behind. Taking a look at a dedicated safety data sheet management system is the first step toward building a workplace that is more resilient, more efficient, and fundamentally safer. Stop chasing paper and start taking control of your chemical safety with a tool built for the real-world challenges of today's regulatory environment.

Common Questions About SDS Management

When you're thinking about moving to a modern chemical safety system, a few questions always seem to pop up. Getting straight answers is the best way to make a smart decision that boosts both safety and efficiency on the floor.

Let's dive into some of the most common questions people ask about a safety data sheet management system. Each one hits on a key piece of the puzzle, from compliance to everyday usability, and helps clarify what it really means to leave old-school manual methods behind.

What’s the Real Difference Between an SDS and an MSDS?

The biggest difference between a modern SDS (Safety Data Sheet) and the older MSDS (Material Safety Data Sheet) is consistency. Before 2012, MSDSs were a bit of a wild west—formats varied from one supplier to the next, which made finding critical information in an emergency a frantic scramble.

When OSHA adopted the Globally Harmonized System (GHS), everything changed. Now, every SDS must follow a strict, easy-to-read 16-section format. This global standard means that vital info, like first-aid steps or the right PPE to wear, is always in the same spot. While you might hear people use the terms interchangeably, only the 16-section SDS is compliant today.

Do We Really Have to Keep Our Safety Data Sheets Updated?

Yes, absolutely. Keeping your SDS library current isn't just a good idea; it's a fundamental OSHA requirement. When a chemical manufacturer learns about a significant new hazard, they have three months to update the SDS. As an employer, the buck stops with you to make sure you have that latest version from your supplier.

This is where a safety data sheet management system becomes a game-changer. The software automates the whole process by constantly checking for new versions. It can even reach out to suppliers for you, so your library stays compliant without you having to manually chase down revision dates.

Staying on top of these updates is crucial for protecting your team from newly identified risks.

Can This Kind of System Connect to Our Inventory Software?

It sure can, and this is where you’ll see some of the biggest benefits. The best platforms are built to integrate directly with the tools you already use, like an Enterprise Resource Planning (ERP) or other inventory management software. This link creates a single, reliable hub for all your chemical data.

Once connected, the system can perform some incredibly useful safety tasks:

- Automated Storage Checks: It can look at where a chemical is stored, check its SDS for hazards, and immediately flag any dangerous combinations.

- Real-Time Quantity Monitoring: The system keeps an eye on your chemical volumes and compares them to regulatory reporting limits, alerting you before you go over.

- Smarter Purchasing: It can even hook into your procurement process to vet new chemicals for restrictions before you place an order.

Ready to stop chasing paperwork and start building a proactive safety culture? See how NextSDS uses intelligent automation to simplify compliance and protect your team. Explore our all-in-one platform at https://nextsds.com.