At its core, a safety instruction card for chemicals is a straightforward, easy-to-digest summary of the most crucial hazard and safety information for a chemical product. It's designed to give workers immediate, practical guidance on safe handling, personal protective equipment (PPE), and what to do in an emergency, right at their workstation.

What Is a Safety Instruction Card and Why It Matters

Think of it like a pilot's pre-flight checklist. The comprehensive flight manual—in our world, the Safety Data Sheet (SDS) for a chemical—contains every single detail you could ever need. But the checklist gives you the essential, life-saving steps for the immediate task.

In the same vein, the safety instruction card doesn't replace the SDS. Instead, it translates its often dense and technical chemical data into clear, direct instructions for workers on the ground. You can learn more about the detailed requirements of a Safety Data Sheet in our guide.

This simple tool is the vital link between complex chemical regulatory documents and genuine, real-world safety. Its job is to make safety information accessible and understandable at a glance, exactly where hazardous chemicals are being used.

The Role in Everyday Chemical Safety

For any Health, Safety, and Environment (HSE) manager, these cards are a cornerstone of a strong chemical safety culture. They empower employees, giving them the confidence and knowledge to handle hazardous substances properly, which helps to minimise risks and stop accidents before they can even start.

A well-designed safety instruction card for chemicals is more than just a box-ticking exercise; it's a frontline defence mechanism. It turns abstract safety rules into practical, life-saving actions that protect your most valuable asset: your people.

By putting this critical information directly into the hands of those who need it most, companies can dramatically lower the chance of chemical incidents. These cards are essential for:

- Preventing Accidents: Clear instructions on chemical handling and storage reduce the risk of spills, accidental exposure, and dangerous chemical reactions from improper mixing.

- Ensuring Correct PPE Usage: The card removes any guesswork by specifying exactly what protective gear is needed for a specific chemical, whether that’s a particular type of glove or a specific respirator.

- Guiding Emergency Response: When an emergency strikes, there's no time to flip through a lengthy document. The card provides immediate first-aid and spill-response steps, allowing for a fast, effective reaction that can make all the difference.

Getting to Grips with Belgian Chemical Safety Law

For any organisation working with chemicals in Belgium, understanding the legal side of things is non-negotiable. This isn't just about ticking boxes; it's about protecting a worker's fundamental right to know exactly what chemical hazards they're dealing with day in and day out. The whole system is built on a framework of core European Union regulations, which have been woven directly into Belgian law.

Two major pieces of legislation really set the stage:

- REACH Regulation (EC) No 1907/2006: This is the big one, covering the Registration, Evaluation, Authorisation and Restriction of Chemicals. It puts the onus squarely on industry to get a handle on the risks their chemicals pose to people and the planet.

- CLP Regulation (EC) No 1272/2008: Standing for Classification, Labelling and Packaging, this regulation makes sure that chemical hazards are communicated clearly and consistently to everyone, using standardised pictograms and statements.

Think of them as a team. REACH manages the chemical's entire journey safely, while CLP makes sure the dangers are obvious to anyone who comes into contact with it.

From Technical Data to Practical Guidance

At the very core of this legal structure sits the Safety Data Sheet (SDS). The SDS is the comprehensive, legally-mandated document that details everything you could possibly need to know about a hazardous substance, broken down into sixteen detailed sections. It's the ultimate source of truth for chemical safety.

But here’s the reality: an SDS is dense. It’s not something you can easily glance at for a quick reminder in a busy workshop or on a factory floor. That's where the safety instruction card for chemicals proves its worth. It acts as a vital bridge, translating the technical jargon of the SDS into clear, straightforward instructions that workers can actually use on the spot. So, while the SDS covers the legal requirement, the instruction card takes care of the practical, everyday safety need.

Real compliance isn’t about having the right paperwork tucked away in a filing cabinet. It’s about making sure that crucial chemical safety information gets to the people who need it most, in a format they can understand and act on instantly.

This is how you build a proactive safety culture—by giving your team the knowledge they need to protect themselves. In Belgium, sticking closely to the SDS requirements laid out by REACH has made a massive difference to workplace safety. In fact, companies that have adopted digital SDS management have seen a remarkable 25% reduction in incidents involving chemicals, largely because automated data handling makes compliance so much easier.

Keeping Compliant Across Borders

When you're dealing with something as detailed as chemical safety laws in Belgium, you have to be certain your safety instruction cards meet every single legal and language requirement. This becomes even more critical for multinational companies, where language barriers can create serious risks when handling chemicals.

Using a professional legal document translation service is a smart move here. It ensures your chemical safety information isn't just translated, but is fully accurate and compliant in the local language. This simple step can prevent huge potential liabilities and, most importantly, helps keep your entire workforce safe, no matter where they are.

Building an Effective Safety Instruction Card for Chemicals

Turning a simple document into a potentially life-saving tool is all about knowing what to include and what to leave out. A great safety instruction card isn’t just a list of rules; it's a masterclass in distillation. It takes the dense, technical information from a chemical's Safety Data Sheet (SDS) and makes it immediately understandable and actionable.

The whole point is to design a card that a worker can glance at and comprehend in seconds, especially when they’re under pressure. Many of the same principles for creating better documentation apply here—think logical flow, simple language, and visuals that draw the eye to the most critical information. The goal isn't just compliance; it's genuine usefulness.

Core Elements of a Powerful Safety Card

Every safety instruction card for chemicals needs to speak a universal language of safety. This consistency is what helps workers instantly recognise dangers, no matter which chemical they happen to be working with on a given day.

Here are the non-negotiable, foundational elements:

- GHS Pictograms: These symbols are instantly recognisable. A flame means flammable, a skull and crossbones means acute toxicity. They provide an immediate visual gut-check on the primary chemical hazards.

- Signal Words: Simple words like "Danger" or "Warning" tell you the level of risk at a glance. "Danger" is reserved for the most severe hazards, while "Warning" covers those that are less severe but still significant.

- Hazard (H) Statements: These are standardised phrases that get straight to the point about the nature of the chemical hazard. For example, “H318: Causes serious eye damage.”

- Precautionary (P) Statements: This is the "what to do" part. These statements give clear, actionable advice on preventing harm, such as, “P280: Wear protective gloves/protective clothing/eye protection/face protection.”

Getting the details right between these components is absolutely vital. For a more detailed look, our complete guide covers everything you need to know about GHS labelling requirements.

The real art of creating a safety instruction card lies in selective extraction. It’s not about copying the entire SDS, but about pulling the most critical, life-saving details that a worker needs in the moment of truth.

Distilling Information From the SDS

To make a card that’s genuinely practical, you need to know exactly where to look within the 16-section SDS for the chemical. This is all about translating comprehensive, technical data into concise, direct instructions that anyone can follow. Think of it as creating a direct line from the source document to what a worker needs to know right now.

The table below shows how the key sections of an SDS map directly onto your safety instruction card, making the whole process much clearer.

Translating SDS Sections to Your Safety Instruction Card

| Information Needed on Card | Primary SDS Section Source | Why It's Critical for Workers |

|---|---|---|

| Product Name & Identifier | Section 1: Identification | Ensures the worker is looking at the correct instructions for the chemical they are actually handling. |

| Hazard Symbols & Warnings | Section 2: Hazards Identification | Provides instant visual recognition of the primary chemical dangers (e.g., flammable, corrosive, toxic). |

| First-Aid Response | Section 4: First-Aid Measures | Gives immediate, life-saving steps to take in case of accidental exposure or injury. |

| Fire-Fighting Instructions | Section 5: Fire-Fighting Measures | Outlines the correct extinguishing media and what not to do, preventing a bad situation from getting worse. |

| Required PPE | Section 8: Exposure Controls/Personal Protection | Specifies the exact gear needed—like nitrile gloves or a specific respirator—to handle the substance safely. |

By focusing on pulling information from these core sections, you ensure the safety instruction card delivers unambiguous guidance for safe handling, emergency response, and personal protection. That’s what makes it a powerful and effective tool for workplace chemical safety.

The Shift From Static Paper to Dynamic Digital Access

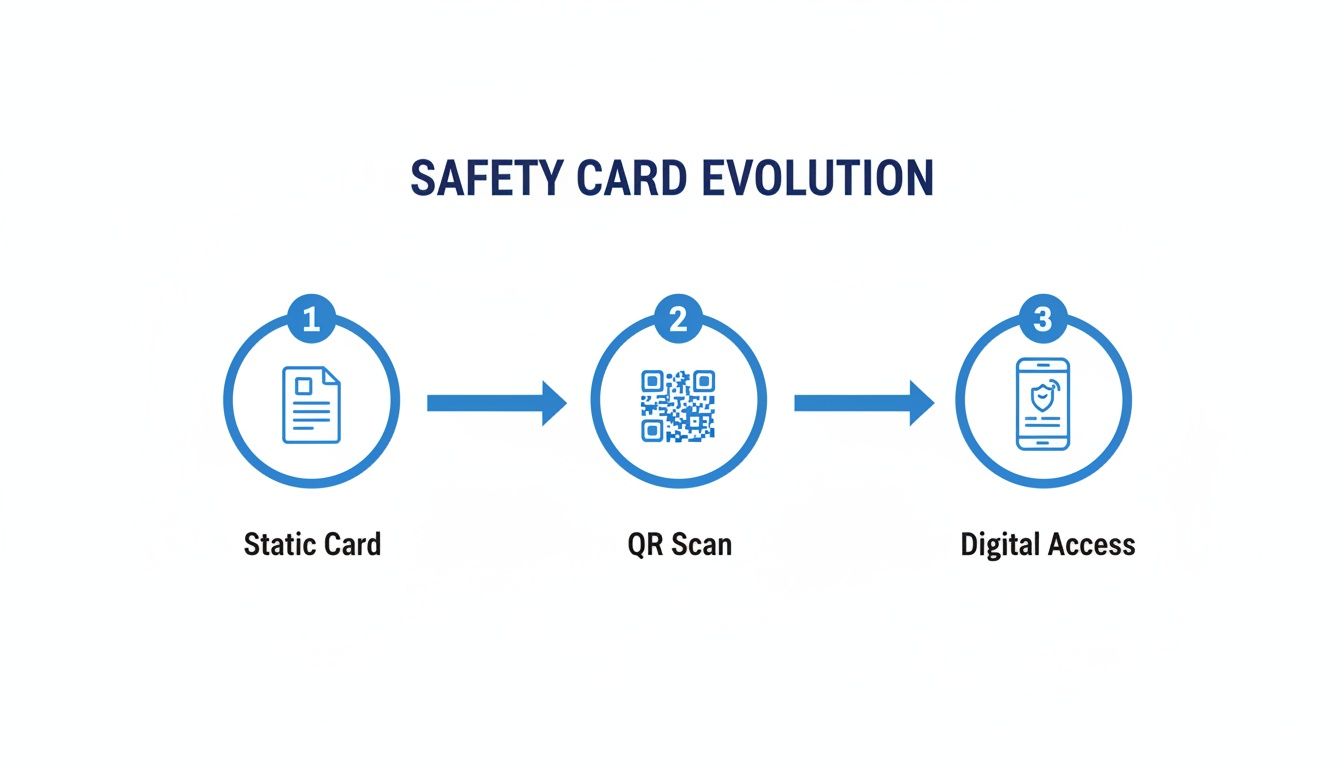

For years, the standard approach to chemical safety information was a laminated card tucked away in a binder. We all know the type. But let's be honest, that system is fundamentally flawed. A paper card is fragile—it can get lost, damaged by a chemical spill, or worst of all, become dangerously outdated the moment a chemical's Safety Data Sheet (SDS) changes.

This isn't just an inconvenience; it's a serious compliance gap. An employee grabbing an old card might use the wrong PPE or follow incorrect first-aid advice for a chemical, potentially turning a minor incident into a major one. The simple truth is that static documents just can't keep pace with the ever-changing world of chemical safety and regulations.

Embracing QR Codes for Instant Access

So, what's the alternative? The future is about moving from static paper to dynamic, digital resources. Modern safety platforms now use QR codes to create a direct link between a physical chemical container and its digital safety instruction card. It’s a simple concept with a powerful impact, ensuring every employee has the latest chemical safety information right in their pocket.

A quick scan with any smartphone or tablet instantly brings up the correct, up-to-date card. This single action eliminates the risk of using outdated information and makes safety protocols far more reliable and accessible, especially for a workforce that’s constantly on the move. You can see how comprehensive SDS management software makes this digital transition smooth and straightforward.

The Real-World Impact of Digital Safety Cards

Switching to digital access is about more than just convenience—it delivers real, measurable improvements to chemical safety and compliance. In Belgium's high-risk sectors, safety instruction cards (often created from SDS summaries) have been a game-changer in reducing accidents.

Consider the findings from a major audit of 450 companies by the Belgian Competent Authority for Chemicals (FOD WASO). It revealed that businesses using digital tools for SDS validation cut their non-compliance fines by a massive 60%, successfully avoiding penalties that averaged €5,000 per violation. This highlights the importance of the Safety Data Sheet as the source of this critical data.

A digital safety instruction card transforms chemical safety from a passive document into an active, on-demand resource. It guarantees that the right information is in the right hands at the exact moment it's needed most.

The benefits are clear in other industries, too. In the life sciences sector, QA/QC teams at biotech hubs in Ghent reported zero major chemical exposures after they brought in QR-accessible cards. This shows a direct link between giving people instant, accurate information and creating a genuinely safer workplace.

Digital cards can also offer multi-language support and direct links to more detailed resources, making chemical safety a universal standard for every single person on site. This isn't just about ticking a compliance box; it's about building a safety programme that is truly and actively protective.

How to Automate Your Safety Card Workflow for Chemicals

Let's be honest, manual compliance is a massive headache for any Health, Safety, and Environment (HSE) team. The grind of creating, updating, and distributing a safety instruction card for chemicals is not just tedious—it's a recipe for mistakes. But what if you could swap that administrative burden for a smooth, automated process that actually makes your workplace safer and more efficient?

That’s exactly what modern compliance platforms are built for. They take the entire lifecycle of a safety card, from creation to update, and make it almost effortless. It all starts with a simple action: uploading a supplier’s Safety Data Sheet (SDS) into the system. From that point on, the heavy lifting is handled for you.

From Manual Data Entry to Instant Extraction

Think about the old way of doing things: a safety officer, highlighter in hand, poring over a dense SDS document to pull out the critical details. Now, imagine a system using smart technology to do that in seconds. The software scans the document and instantly extracts the most important information needed for a clear and compliant safety instruction card for chemicals.

This isn't just about speed; it's about accuracy. The system zeroes in on the essentials:

- Hazards and Pictograms: It identifies the specific chemical risks and pulls the corresponding GHS symbols.

- PPE Requirements: It pinpoints exactly what personal protective equipment is needed for safe handling.

- First-Aid Measures: It highlights the immediate steps to take if something goes wrong.

- Emergency Contacts: It makes sure the right phone numbers are front and centre.

Once this data is captured, the platform generates a concise, easy-to-read, and fully compliant safety card that’s already optimised for mobile phones. This card is then linked to a unique QR code, ready to be printed and stuck on chemical containers or displayed at workstations. All it takes is a quick scan from any employee to get the information they need, right when they need it.

This simple visual shows just how far we've come—from static paper cards that are outdated the moment they're printed to dynamic, on-demand digital information that's always current.

A Strategic Partner in Compliance and Risk Reduction

The real power of automation goes well beyond just creating the first card. A good system acts as a vigilant partner for your entire chemical safety programme. It doesn’t just sit there; it actively monitors for any updates to the original SDS from your suppliers. When a new version is released, the platform immediately flags it.

This triggers an automatic alert to your HSE team. They can review and approve the changes with a click, and every digital safety instruction card linked to that chemical is updated instantly across the whole organisation. Anyone scanning the QR code from that moment on sees the latest, most accurate safety advice. It completely eliminates the risk of someone using outdated chemical information in a critical moment.

The story of the safety instruction card in Belgium really highlights this need for accuracy, especially with the push for EU harmonisation under REACH and CLP regulations. Since eSDSs became mandatory for dangerous substances over 10 tonnes, Belgian industries have reported a 35% improvement in regulatory adherence. With non-EU imports on the rise, having a tool that guarantees CLP/GHS accuracy isn't just a nice-to-have; it's essential for maintaining that high standard. You can discover more insights about REACH and SDS requirements to get a fuller sense of the regulatory landscape.

By automating these crucial checks, technology transforms the safety instruction card from a static piece of paper into a living, reliable safety tool. It ensures your chemical safety programme is always accurate and compliant, which dramatically reduces risk and frees up your team to focus on what really matters: proactive safety initiatives.

Answering Your Questions About Safety Instruction Cards for Chemicals

Even when the concept is clear, practical questions always come up. Let’s tackle some of the most common ones that people ask when putting safety instruction cards into practice, making sure your chemical safety programme is both effective and compliant.

What’s the Real Difference Between an SDS and a Safety Instruction Card?

Think of it like this: a Safety Data Sheet (SDS) is the full, unabridged technical manual for a chemical. It’s a comprehensive, legally required document, often running 10 pages or more, covering every conceivable detail from toxicological data to its specific chemical composition. It's the ultimate source of truth.

A safety instruction card for chemicals, on the other hand, is the quick-start guide. It’s designed for the person on the shop floor. It pulls out only the most critical, need-to-know information from the SDS—like what PPE to wear, the immediate first-aid steps, and the main hazard symbols—and puts it into a simple format right at the workstation. The card is for a quick glance, while the SDS is for a deep dive.

How Often Should Safety Instruction Cards Be Updated?

The rule is simple: a safety instruction card must be updated the moment the source SDS for that chemical changes. An SDS can be revised for all sorts of reasons—new information on hazards might come to light, the product's formula could be tweaked, or regulatory classifications might be updated.

Your safety card is only as good as the data it's based on. An outdated card is a serious risk, which is why having a system that automatically tracks SDS revisions is so vital for keeping everyone safe and compliant.

This is where traditional paper-based systems really fall down. It's all too easy for a new SDS to be filed away in a binder while the old, incorrect cards are still in use out on the floor. Digital systems fix this problem by flagging any revision and ensuring all linked cards are updated instantly.

Are Digital Safety Instruction Cards Actually Compliant?

Yes, for the most part, digital formats are perfectly fine with regulators, as long as every employee can easily get to them at their worksite. The core principle behind regulations like REACH and OSHA's Hazard Communication Standard is the "right to know." If a worker can get the chemical safety information they need, right when they need it, the format doesn't really matter.

The key word here is accessible. A worker needs to be able to scan a QR code or use a nearby terminal without hunting down a supervisor or asking for permission. To be compliant, the access must be direct and immediate.

What's the Best Way to Train Employees to Use These Cards?

Good training is what turns a safety card from just another piece of paper into an ingrained safety habit. It’s not enough to just hand them out; your team needs to understand why they're important and how to use them in a real-world chemical safety situation.

Here are a few practices that genuinely work:

- Make it part of day one: Build safety card training right into the onboarding for any new starter who will work with or near hazardous substances.

- Run hands-on drills: Don't just talk about it. Stage mock scenarios where employees have to use a card to grab the right PPE or find the correct first-aid response for a simulated chemical spill.

- Use toolbox talks: Pick a specific chemical's safety card and make it the focus of a quick daily or weekly toolbox talk. It’s a great way to keep the information top-of-mind.

- Check for understanding: Don't just show them the card—ask them questions. Make sure they can explain what the pictograms mean and what the precautionary statements are telling them to do.

The end goal is to build muscle memory. In a real emergency, you want looking at that card to be an automatic reaction, not a fumbled afterthought. This kind of consistent reinforcement is what builds a genuine chemical safety culture.

Ready to stop wrestling with manual data entry and outdated paper cards? NextSDS offers a smarter, automated way to manage your entire chemical safety process, from AI-powered SDS extraction to instantly creating mobile-ready safety cards with QR codes. Make sure your team always has accurate, compliant information right at their fingertips. Discover how NextSDS can simplify your safety management.