Here's a common scenario I've seen play out too many times: a maintenance tech grabs an unmarked spray bottle, assuming it’s just a cleaner. A few moments later, they realize it’s actually a corrosive solvent. This isn't just a hypothetical situation; it's a real-world risk that underscores why secondary container labeling is an absolute must-have, frontline defense against chemical hazards.

Simply put, it’s the practice of labeling any container you transfer a chemical into from its original package.

Why You Can't Afford to Ignore Secondary Container Labeling

Honestly, failing to properly label secondary containers is one of the most dangerous—and unfortunately, most common—gaps in workplace safety programs. A secondary container isn't just something you'd find in a lab; it’s any vessel that isn’t the original one shipped from the manufacturer.

Think about all the containers used daily in most facilities:

- Spray bottles for cleaning or application

- Jugs and carboys for bulk liquids

- Beakers and flasks for mixing

- Totes and small tanks for temporary storage

Every time a chemical is poured into one of these, all its vital safety information gets left behind with the original drum or bottle. The person who did the transfer might know what's inside, but what about their coworker on the next shift? That knowledge gap is a serious accident waiting to happen, and it's exactly what regulators are trying to prevent.

The Rules Behind the Labels

The "why" is all about stopping accidents before they start. In the United States, OSHA’s Hazard Communication Standard (29 CFR 1910.1200) is crystal clear: every secondary container must be labeled with the product identifier and words, pictures, symbols, or a combination that provides the specific hazard information.

This isn't a minor rule that regulators overlook. Hazard Communication consistently lands on OSHA's top-cited standards list. In fiscal year 2023 alone, it was responsible for roughly 2,450 citations, and a significant chunk of those involved unmarked or improperly labeled containers.

Key Takeaway: An unlabeled container is not just a compliance headache—it’s an active hazard. Proper labeling turns a potential danger into a clearly communicated risk that anyone can understand at a glance.

This practice goes far beyond just avoiding fines. It’s about creating a foundational culture of chemical safety in the workplace. When done right, any employee can instantly see what they're handling and know the risks involved. Without this simple step, even the most detailed safety programs can fall apart right at the point of use.

The Anatomy of an Effective and Compliant Safety Label

A compliant secondary container label is far more than a box to check on an audit form—it's a critical communication tool that keeps your team safe on the floor. While regulations like GHS and OSHA set the baseline, a truly effective label goes beyond that by providing instant clarity and actionable information.

Let's break down what makes a label both compliant and genuinely useful.

A poorly made label can be just as dangerous as no label at all. A spray bottle with "Degreaser" scrawled on it in marker doesn't tell an employee if it's a mild soap or a corrosive chemical that demands gloves and eye protection. When it comes to safety, that kind of ambiguity is a risk you can't afford.

Core GHS Label Elements

Every GHS-compliant label, whether on the original drum or a smaller spray bottle, needs a few key pieces of information. Think of these as the non-negotiables that create a quick, at-a-glance safety summary.

- Product Identifier: This name has to match what’s on the Safety Data Sheet (SDS). "Cleaner" won't cut it. You need the specific trade name, like "ACME Industrial Solvent X-42."

- Signal Word: This gives a quick read on the hazard level. "Danger" is reserved for the more severe hazards, while "Warning" is used for less severe ones. A label will only ever have one, and it's always the one that corresponds to the most serious hazard.

- Hazard Pictograms: These are the iconic red-bordered, diamond-shaped symbols that everyone recognizes. They give immediate visual clues about the risks, whether it's flammability, corrosion, or toxicity.

- Hazard Statements: These are standardized phrases that get straight to the point, describing the nature of the hazard. For example, "Causes severe skin burns and eye damage" or "Highly flammable liquid and vapor."

These are the absolute fundamentals of compliance. For a much deeper dive into each of these mandatory parts, check out our guide on GHS labeling requirements.

Elevating Safety with Best Practices

Meeting the GHS requirements is the bare minimum. Adding a few more details to your labels can make a massive difference in real-world safety and turn a compliant label into a truly protective one.

Expert Tip: Never underestimate the power of context. The best labels answer the questions an employee might have before they have to ask, especially in an emergency. Adding PPE requirements and contact info bridges that critical gap between identifying a hazard and taking safe action.

Consider building these recommended elements right into your standard label templates:

- Date of Transfer/Expiration: Many chemicals degrade over time, sometimes becoming more hazardous. Tossing a "filled on" date onto the label is great for inventory control and ensures no one is using an expired, ineffective, or dangerous product.

- Required Personal Protective Equipment (PPE): Don’t make your team hunt through an SDS to figure out what to wear. Simple icons or a quick line of text specifying "Safety Goggles Required" or "Wear Nitrile Gloves" provides instant, clear direction.

- Emergency Contact Information: If a spill or exposure happens, who should they call? Putting an internal number (like the EHS manager's extension) or "Call Poison Control" on the label can save precious seconds when it matters most.

From Illegible to Instructive

Picture the difference between a smudged, handwritten label and a crisp, system-generated one. One creates confusion and risk; the other projects a culture of safety and precision.

This is exactly why modern EHS platforms have built-in label printing. It removes the guesswork and human error, guaranteeing every label is clear, durable, and 100% compliant. Effective secondary container labeling is built on this very foundation of consistency and clarity.

Building a Smart and Scalable Labeling Workflow

Let's be honest: an ad-hoc approach to secondary container labeling is a recipe for disaster. Relying on handwritten labels or digging through dusty, outdated SDS binders just doesn't cut it. It leads to inconsistency, risk, and—sooner or later—an incident or a compliance fine. A truly effective system needs a single source of truth, ensuring every label is accurate and standardized across the board.

The foundation of a modern, reliable labeling process is a centralized, digital SDS management platform. When you use a system like NextSDS, you take all the dangerous guesswork out of the equation. Instead of having an employee flip through a binder and manually copy information (and potentially make a critical mistake), they can instantly pull validated hazard data from the most current version of a product's SDS.

This simple shift transforms labeling from a dreaded chore into a seamless, nearly error-proof process. You can create standardized label templates for any container you use, from small spray bottles to large totes, knowing that every critical piece of information—product identifier, pictograms, and hazard statements—is present and correct every single time.

Centralizing Data for Unshakeable Consistency

When your SDS data lives in one central hub, it doesn't matter who prints a label or when they do it—the information will always be identical and pulled from the same approved source. This is a massive leap forward from relying on individual memory or scattered paper records, where information gets outdated or misinterpreted faster than you can say "OSHA."

With a platform as your command center, your team can:

- Generate On-Demand Labels: Employees can print compliant GHS labels right at the point of use. A newly filled container should never be left unmarked, even for a minute.

- Standardize Templates: You can create and lock down pre-approved templates for different container types, guaranteeing all mandatory and recommended information is included.

- Eliminate Manual Entry Errors: By pulling data directly from the SDS, you completely remove the risk of typos or incorrect hazard information being transcribed onto a label.

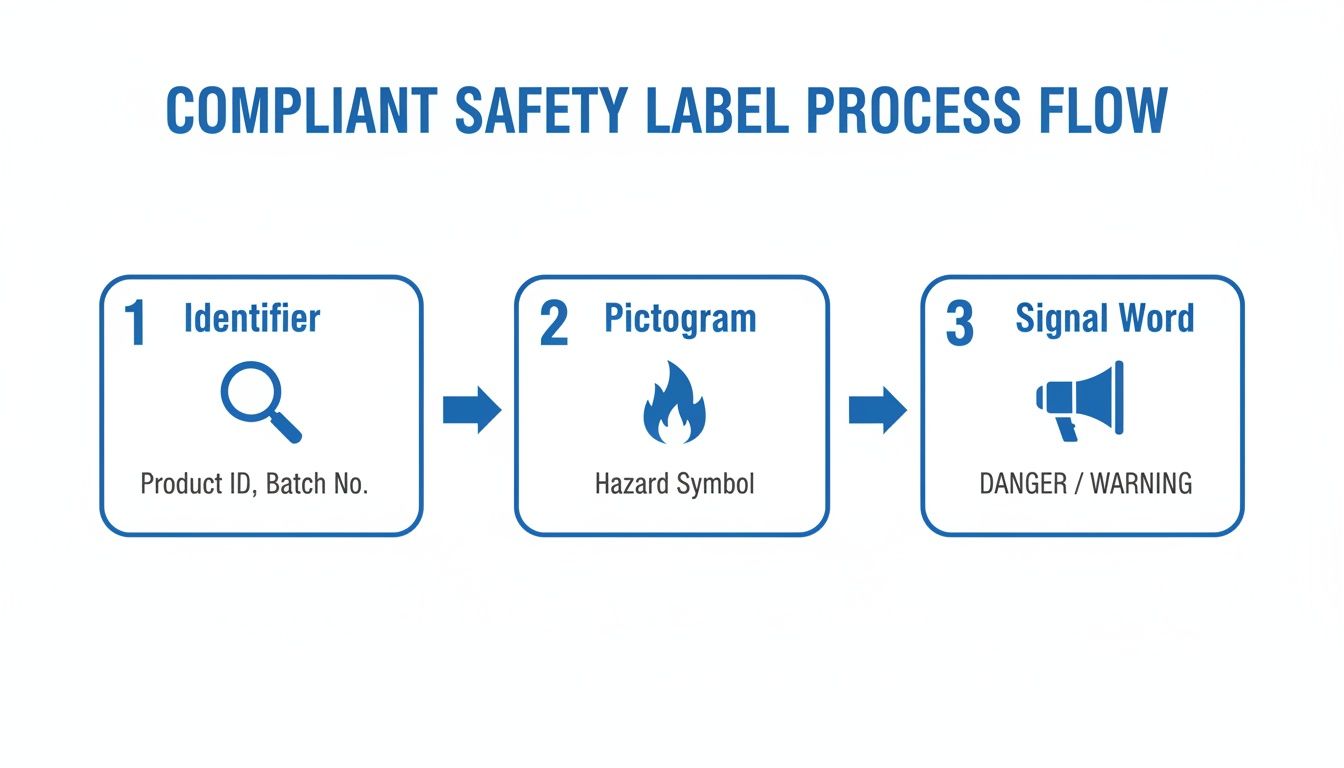

This simple process flow shows how the most critical GHS elements come together to form a compliant label.

As you can see, it’s all about that essential trio: the identifier, pictogram, and signal word. They're the core of at-a-glance hazard communication and the first thing an employee sees.

Integrating Modern Tools for Next-Level Safety

Today's best labeling workflows are built on smart technology. More and more organizations are connecting their on-demand label printing directly with their core EHS systems. Why? Because it closes a dangerous gap. Historically, it wasn't uncommon for 20–30% of SDS inventories at large sites to be out of date. Pulling GHS data in real-time from a central source fixes that. It’s no surprise the automatic labeling machine market is projected to hit $4.39 billion by 2032, driven by this need for reliable automation.

One of the most powerful and practical tools you can add to your workflow is the humble QR code.

My Pro Tip: Putting a QR code on your secondary container labels is a total game-changer. It creates a direct, instant link from the physical container in a worker's hand to the full, up-to-date Safety Data Sheet on their phone. This simple step gives them comprehensive safety information in seconds.

This makes your safety program incredibly scalable and robust. An employee can scan the code to immediately access detailed PPE requirements, first-aid measures, and spill procedures without ever leaving their workstation to hunt for a binder or log into a computer.

As you design your labels, you might also want to look into professional label printing services to ensure the final product is durable and legible enough for your specific work environment. It's the final step in closing the loop on safety—making comprehensive data accessible right where it's needed most.

Common Labeling Mistakes and How to Fix Them

Even with the best intentions, mistakes on secondary container labels are bound to happen. The trouble is, these small oversights are frequently the very things that lead to hefty compliance fines and—much worse—workplace injuries that were entirely preventable. After years of walking through facilities and conducting safety audits, I've seen the same issues pop up time and again. Let's dig into these common pitfalls and, more importantly, how to fix them for good.

One of the biggest culprits? The good ol' Sharpie. A handwritten label might feel like a quick, common-sense solution, but it’s a recipe for disaster. These labels inevitably smudge, fade, or get washed away by chemical splashes, often becoming completely unreadable before the next shift even clocks in.

Vague or Incomplete Information

A label that just says "Cleaner" is a massive red flag. Is it a gentle soap solution or a corrosive acid that requires gloves and goggles? That ambiguity creates a huge safety risk. I also see a lot of internal codes or abbreviations that mean something to one supervisor but leave everyone else guessing.

How to Fix It: This one's simple but non-negotiable. Always use the full product identifier exactly as it's listed on the Safety Data Sheet. Ditch the handwritten notes entirely and move to a system where you can print durable, chemical-resistant labels directly from your SDS management platform. This ensures every single label is clear, consistent, and legible.

The "Temporary" Unlabeled Container

We've all heard the excuse: "I'm just using it for five minutes, I'll label it later." This is easily one of the most dangerous habits in a workplace. An unattended, unlabeled container is a complete mystery. To anyone walking by, it's an unknown hazard, even if you only left it for a moment.

A Critical Reminder: There is no grace period for an unlabeled container. The second a chemical is transferred and left unattended, it's a direct violation and an immediate risk to everyone in the area.

This mistake is all about workflow. The solution is straightforward: no container gets filled unless a label is printed and ready to be applied. By making on-demand label printing stations accessible right where chemicals are dispensed, you remove the temptation to cut corners. It builds a culture where proper labeling is just part of the process.

Outdated Hazard Information

This is a more subtle—and therefore more dangerous—mistake. A supplier might update an SDS with new hazard warnings or required PPE, but if your team is still printing labels from an old version you have saved, you're actively spreading incorrect safety information. This gap can lead to people using the wrong gloves or taking inadequate precautions.

To avoid this, your labeling process needs to be directly connected to a live, updated SDS library. A system that automatically flags when an SDS has been revised is crucial. This connection ensures that every label you print reflects the most current, accurate hazard data straight from the manufacturer, closing a critical safety loop.

How to Keep Your Labeling Program on Track

Let's be clear: a secondary container labeling program isn't something you can just set up and walk away from. Think of it as a living system that needs regular check-ups to stay healthy, accurate, and effective. The best way to do this is by building a routine audit process to catch compliance gaps before they snowball into safety incidents or, worse, regulatory fines. This isn't about micromanaging your team; it's about creating a sustainable culture of safety.

The simplest way to start is by just walking the floor. Seriously. Grab a clipboard or a tablet and do some spot-checks on the secondary containers people are actually using. Don't just glance to see if a label is there—really look at it. Is it legible? Is it smudged, damaged, or peeling off? The details matter.

Conducting a Real-World Labeling Audit

Your walkthrough should be guided by a few key questions. This isn't a formal, white-glove inspection. It's a practical health check of your day-to-day labeling habits.

Here’s a simple checklist I use to get started:

- Presence and Condition: Is every single secondary container labeled? And I mean every single one. Are the labels themselves holding up, or are they peeling, faded, or covered in grime?

- Information Accuracy: Does the Product Identifier on the label exactly match the Safety Data Sheet (SDS)? No abbreviations, no nicknames.

- GHS Compliance: Are the GHS pictograms and the correct signal word actually on there? These are non-negotiable.

- Consistency: What are you seeing out there? Standardized, printed labels, or a chaotic mix of handwritten notes and inconsistent formats?

This process does more than just spot one-off mistakes. It reveals patterns. For instance, if you keep finding faded, unreadable labels in one specific area, that’s a huge clue. It probably means you need to switch to a more durable, chemical-resistant label stock for that environment.

It's All About Continuous Improvement and Training

A physical audit is only half the battle. Your program's long-term health depends entirely on your team. An effective secondary container labeling program is only as strong as the people putting those labels on bottles every single day. One annual training session just won't cut it.

You have to keep the conversation going. Weave labeling checks into your regular safety meetings or toolbox talks. A quick five-minute review of a common mistake you've noticed or a simple reminder of why these rules exist can keep the topic fresh and relevant.

My Two Cents: The point of an audit isn't to play the blame game. It’s about finding weak spots in your system. When your team sees auditing as a tool to make things better for everyone, they’ll stop dreading it and start actively participating in creating a safer workplace.

As supply chains get more complex, the scale of this challenge is mind-boggling. The global labels market is expected to hit $89.7 billion by 2035. At that volume, even a tiny error rate can impact millions of products. This makes a solid auditing program critical not just for safety, but for your entire operational integrity. You can get a sense of the scale of industrial packaging from industry market reports.

Ultimately, consistent auditing and ongoing training are what turn proper labeling from a chore into a shared responsibility. It builds a workplace where everyone understands their role in preventing chemical hazards, making safety truly second nature.

Common Questions About Secondary Container Labeling

Even with a solid plan in place, a few common questions always seem to surface when teams start implementing a secondary container labeling program. Getting these right is the key to building a safety culture that actually works in the real world. Let's tackle some of the most frequent ones I hear from safety managers.

The "Immediate Use" Gray Area

One of the biggest points of confusion is the "immediate use" exception. People often ask, "Can I just pour a chemical and use it right away without a label?"

The short answer is yes, but this exception is razor-thin and, frankly, dangerous to rely on. OSHA's rule is very specific: it only applies when a single person transfers the chemical and uses all of it during their shift. The moment that container is left unattended, stored for later, or passed to someone else, it must be labeled.

Leaning on this exception is a bad habit. It creates ambiguity and puts safety at risk if someone gets called away unexpectedly or a shift change happens.

The Safest Bet: Just label every container, every time. It’s a simple rule that eliminates any guesswork and ensures safety doesn't hinge on someone's memory or schedule.

Choosing Label Materials That Last

"What kind of label should we use?" This is a fantastic question because a label you can't read is just as bad as no label at all.

Forget standard paper labels. They'll peel, smudge, or disintegrate the first time they get splashed with a chemical or exposed to a little moisture. In an industrial environment, you need something much tougher. Think durable, synthetic materials like polyester or vinyl that can stand up to chemicals, grease, and abrasion.

The printing method is just as important. Thermal transfer printing with a resin ribbon creates a bond that's far more resilient than a standard office inkjet. Your goal is a label that stays legible for the entire life of the container.

Sticking with Old Labeling Systems

Another common question is whether older systems, like the HMIS or NFPA diamonds, are still okay to use instead of GHS labels.

OSHA does technically allow alternative workplace labeling systems, but there’s a big catch. You have to prove that your system provides all the same critical hazard information as a GHS label, and every single employee needs to be trained on how to interpret it. If you want a refresher on the core principles, this guide on GHS and SDS compliance is a great resource.

While it's allowed, mixing systems can create unnecessary complexity and confusion. The most straightforward and reliable path is to stick with the globally recognized GHS format. Using the standard pictograms, signal word, and hazard statements ensures everyone is on the same page, from the supplier's SDS straight to the shop floor.

Ready to eliminate labeling errors and ensure 100% compliance? NextSDS centralizes your Safety Data Sheets and enables your team to print accurate, durable GHS-compliant labels on-demand. Streamline your entire chemical safety workflow and protect your team with a smarter, more reliable system. Discover how NextSDS can transform your safety program today.