When you transfer a hazardous chemical from its big, original container into a smaller one for everyday use, you need a way to track what's inside. That's where a secondary container label comes in. Think of it as the new ID card for that spray bottle, beaker, or jug you just filled. Its entire purpose is to make sure anyone who picks it up knows exactly what it is and how to handle it safely, preventing dangerous mix-ups.

Why Secondary Container Labels Are a Safety Non-Negotiable

Picture this: in a busy workshop, someone pours a powerful cleaning concentrate from its large, well-labelled drum into a plain, unmarked spray bottle. It’s a task that happens every day, but it creates an immediate and serious hazard. That unlabelled bottle is now a complete unknown, a common blind spot in workplace safety that can have devastating consequences.

This is exactly why secondary container labels are your first and most vital line of defence. They close the critical information gap that opens the second a chemical leaves its original, manufacturer-supplied packaging.

Defining Secondary Containers

So, what exactly counts as a secondary container? It's simply any vessel you transfer a hazardous chemical into from its original container (the one you got from the manufacturer). This covers a huge range of items you probably use all the time:

- Spray bottles holding diluted cleaning solutions

- Beakers and flasks in a laboratory setting

- Jugs used for pouring solvents

- Smaller drums for temporary storage on-site

The rule of thumb is simple: if you move a hazardous substance into a new container, that new container needs a new label. This isn't just about ticking a compliance box; it's a fundamental practice for keeping your team safe.

The moment a chemical is in an unlabelled container, it stops being a useful tool and becomes an unidentified risk. In an emergency, that lack of information can mean delayed first aid, the wrong firefighting tactics, or serious environmental harm.

The Real-World Risks of Unmarked Containers

Forgetting to use secondary container labels isn't a minor oversight—it creates immediate and serious dangers. An unmarked bottle of corrosive cleaner could easily be mistaken for water, leading to accidental ingestion or severe skin burns. If there’s a spill, how would emergency responders know what they're dealing with? Without a label, their ability to control the situation safely is severely compromised.

This isn't just a concern for industrial chemicals, either. Think about a professional kitchen, where strict adherence to restaurant food storage guidelines depends on everything being clearly marked to prevent cross-contamination and ensure food safety.

Proper labelling is an active, ongoing safety measure. It ensures that critical hazard information travels with the chemical, no matter where it goes. It’s a cornerstone of effective chemical safety in the workplace. These labels empower every employee to identify a substance and its risks at a glance, allowing them to work safely and react correctly when it matters most.

Getting to Grips with GHS and CLP Regulations

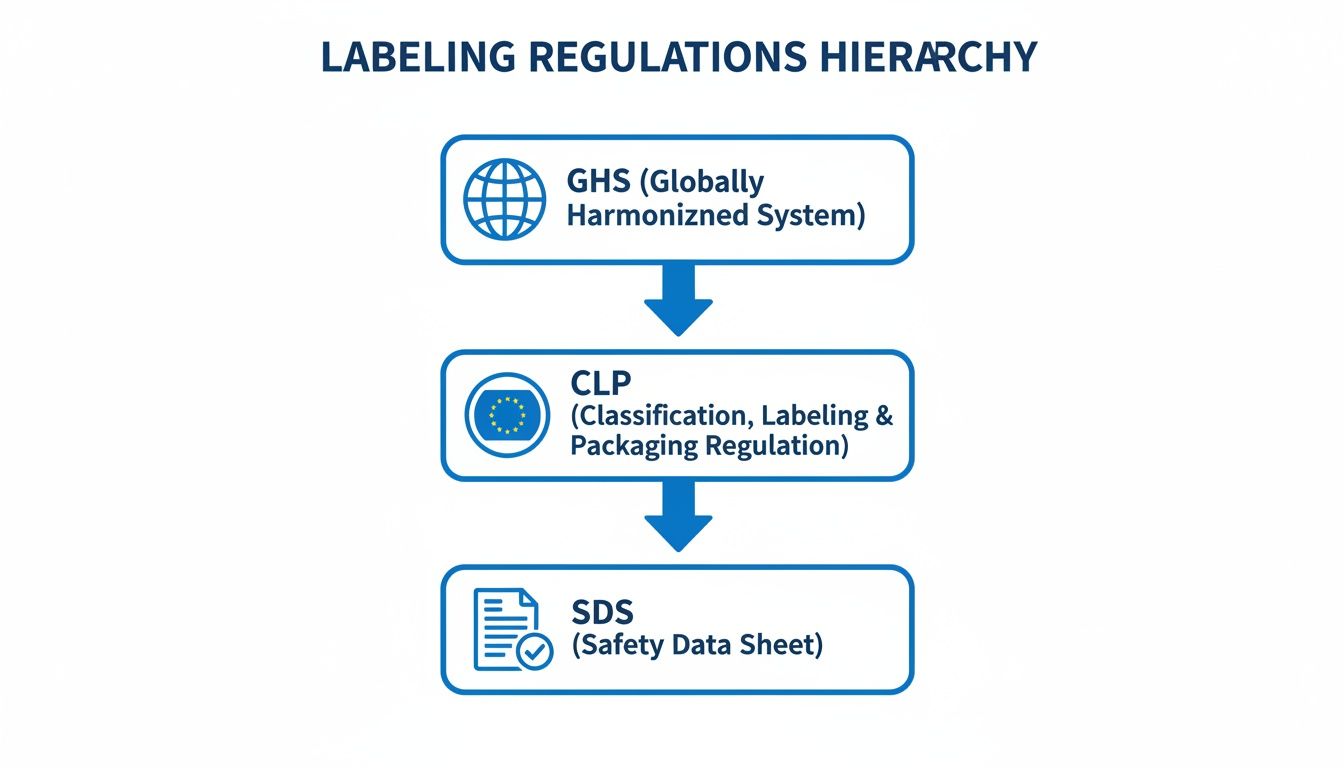

The rules for secondary container labels can seem a bit tangled at first, but they all stem from one simple, powerful idea: creating a universal language for chemical safety. This global standard is the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). You can think of it as the master blueprint for communicating chemical hazards anywhere in the world.

The whole point is to make sure a worker in Brussels understands the same danger symbols and warnings as a colleague in Brisbane. This consistency is absolutely essential for workplace safety, especially for any company that's part of an international supply chain.

In the European Union, the GHS blueprint is brought to life through a specific regulation called CLP (Classification, Labelling and Packaging). While it mirrors GHS closely, CLP has its own regional tweaks, making it the definitive legal framework for chemical safety across Europe.

The Foundation of Workplace Compliance

If you're a Health, Safety, and Environment (HSE) manager, getting GHS and CLP right isn't just a "nice-to-have"—it's the very bedrock of a compliant chemical management programme. These regulations spell out precisely what information must be on the labels of chemicals used in your facility.

It's important to remember these are different from the labels needed for shipping, which are covered by separate transport laws. A workplace secondary container label is for the people handling the chemical day in, day out, giving them immediate, clear safety advice. And where does all this vital information come from? It's all pulled directly from the chemical's Safety Data Sheet (SDS).

Understanding GHS and CLP labelling also fits into the bigger picture of facility safety, like the classification of hazardous locations. Knowing how different areas are zoned based on risk just hammers home why having accurate, compliant labels is so critical.

When Is a Full GHS Label a Must?

A question that comes up all the time is when you need a full-blown GHS/CLP label versus when a simpler, in-house version will do. The rule is quite clear: if you pour a chemical into a secondary container and it won't be used up completely by one person within a single work shift, it must have a full, compliant label.

So, if that container is going to be:

- Left unattended for any length of time.

- Handed over to another employee.

- Stored for someone else to use on a later shift.

Then it absolutely needs a label with all the mandatory elements. The danger of an unlabelled or poorly marked container being picked up and misused is just too great. And the penalties for getting this wrong are serious; in the US, for example, OSHA violations for hazard communication shot up by 19% in just one year, which shows how closely regulators are watching.

The "immediate use" exemption is incredibly narrow and should be used with extreme caution. If you have even the slightest doubt, the safest and most compliant choice is always to put a full secondary container label on it. Trying to rely on that exemption is an easy way to end up with a major compliance headache.

The Unbreakable Link: From SDS to Label

The Safety Data Sheet (SDS) is the single source of truth for creating any secondary container label. Every bit of information you need—from the product name to the exact hazard warnings—is laid out in its 16 sections.

This direct link ensures the information your team sees on a spray bottle or a decanted jug is a perfect match for the detailed data provided by the manufacturer. This seamless flow of information is what hazard communication is all about. You can dive deeper into the specific components by reading our detailed guide on GHS labeling requirements.

Ultimately, mastering these regulations is about building a system you can trust. It's about ensuring that every time a chemical is poured into a new container, the crucial safety information travels with it, protecting your team and keeping your operations compliant. Getting these rules wrong can lead to hefty fines, but more importantly, it can put the safety of your entire workforce at risk.

What Goes on a Compliant Secondary Label?

A good secondary label needs to tell a clear, immediate story about what's inside the container. It’s not just about ticking boxes for compliance; it's about giving your team the information they need, at a glance, to stay safe. Let's break down exactly what that looks like under the GHS and CLP regulations.

The whole system is designed to be a logical pyramid. Global standards like GHS set the foundation. Regional laws like CLP adapt those rules. And all that crucial information is distilled into the Safety Data Sheet (SDS), which then tells you precisely what needs to go on your labels.

This hierarchy shows why the SDS is your single source of truth. It’s the direct link between global safety standards and the secondary container labels your team uses every single day.

The Non-Negotiables: GHS and CLP Mandated Elements

Under GHS (and its European implementation, CLP), every secondary label absolutely must include a core set of elements. These are pulled directly from the chemical’s Safety Data Sheet (SDS) and form the bedrock of workplace chemical safety. Think of them as the legal minimum.

Product Identifier: This has to be the exact name or number for the chemical as it appears on the SDS. No nicknames or abbreviations. This consistency is vital so anyone can quickly find the right SDS in an emergency.

Signal Word: This is a single word—either “Danger” or “Warning”—that signals the hazard level. Danger is used for the most severe hazards, while Warning flags less severe ones. You only ever use one of them—whichever represents the highest risk.

Hazard Pictograms: These are the symbols you see inside a red-bordered diamond. They’re designed to be instantly recognisable, providing a quick visual warning about the type of hazard (flammable, corrosive, toxic, etc.) that cuts through language barriers.

Hazard Statements: These are standard phrases that spell out the specific nature of the risks. For example, a pictogram might show something is corrosive, but the hazard statement clarifies with, “Causes severe skin burns and eye damage.”

Precautionary Statements: If hazard statements describe the risk, precautionary statements tell you what to do about it. They give practical advice on prevention, response, storage, and disposal, such as “Wear protective gloves and eye protection.” For a deeper dive, check out our full guide to GHS label requirements.

Going Beyond Compliance: Best-Practice Additions

Meeting the GHS/CLP requirements is mandatory, but a truly robust safety culture goes a little further. Adding a few extra pieces of information to your secondary container labels can make a huge difference in clarity and safety on the ground.

To help you distinguish between what's legally required and what's just a really good idea, we've put together a simple table.

Mandatory vs Recommended Label Elements

| Label Element | Requirement Level | Purpose and Key Details |

|---|---|---|

| Product Identifier | Mandatory | Must match the name/code on the Safety Data Sheet for easy cross-referencing. |

| Signal Word | Mandatory | A single word ("Danger" or "Warning") indicating the severity of the hazard. |

| Hazard Pictograms | Mandatory | Standardised symbols in a red diamond that provide an immediate visual warning. |

| Hazard Statements | Mandatory | Standard phrases that describe the specific nature of the chemical's hazards. |

| Precautionary Statements | Mandatory | Actionable advice covering prevention, response, storage, and disposal. |

| PPE Guidance | Recommended | Simple icons or text (e.g., gloves, goggles) serve as a quick visual safety reminder. |

| First-Aid Instructions | Recommended | Basic, life-saving steps to take immediately following an exposure. |

| Transfer Date | Recommended | Helps with stock management and ensures chemicals are used within a safe timeframe. |

| Employee Initials | Recommended | Adds a layer of personal accountability for the person who filled the container. |

As you can see, the recommended elements bridge the gap between compliance and practical, everyday safety.

A compliant label meets the minimum legal standard. A great label anticipates what the user needs in a real-world situation, giving them practical information that prevents accidents before they happen.

By combining the mandatory information with these smart additions, you build a labelling system that doesn't just satisfy regulators but actively protects your people.

Creating a Durable and Effective Labelling System

A perfectly compliant secondary container label is useless if it falls off, fades into illegibility, or turns to mush after a chemical splash. In the real world, a label that can't withstand its environment is a compliance failure just waiting to happen. Building a labelling system that lasts is every bit as important as getting the information right in the first place.

The secret to a durable label boils down to one critical choice: the material. Let's be honest, a standard paper label from the office printer just won't cut it in most industrial settings. You need materials that are engineered to handle the specific challenges of your workplace.

Choosing the Right Label Materials

The right material isn't a one-size-fits-all solution; it depends entirely on the environment and the chemicals the container will encounter. Think about what your labels will face day in and day out—moisture, abrasion, extreme temperatures, or direct chemical contact?

Chemical-Resistant Polyester: This is the go-to choice for workplaces dealing with harsh solvents and chemicals. These labels have a non-porous surface that stops ink from being absorbed or smudged, keeping everything crisp and readable even after a splash. They are perfect for labs and manufacturing floors.

Durable Vinyl: If your containers are stored outdoors or in areas with lots of moisture and UV exposure, vinyl is an excellent option. It's flexible, waterproof, and fights off fading from the sun, making it ideal for drums and tanks that live outside.

High-Tack Adhesives: The label material is only half the story; the adhesive that sticks it to the container has to be just as tough. A high-tack or industrial-grade adhesive is essential to ensure the label stays put on all sorts of surfaces, from smooth glass beakers to rough, textured plastic drums.

Skimping on label materials is one of the most common and costly mistakes you can make. Trying to save a few pounds on cheaper labels often leads to the constant, frustrating job of re-labelling and, far more seriously, the danger of unidentifiable containers.

Design and Placement for Maximum Visibility

A durable label still needs to be seen and understood in a split second. Smart design and thoughtful placement are crucial for communicating hazards quickly and clearly, especially when an emergency strikes.

Here are a few practical design tips for your secondary container labels:

Font Size and Legibility: Stick with a clean, sans-serif font (like Arial or Helvetica). Most importantly, make sure the text is large enough to be read from a safe distance. Small, fancy fonts might look nice, but they become impossible to read when smudged or viewed from across the room.

Colour Contrast: High contrast is your best friend. Black text on a white or yellow background is a classic combination for a reason—it’s incredibly easy to see in almost any lighting condition.

Proper Placement: Always apply the label to a clean, smooth, and dry part of the container's main body. Don't put labels on lids, which can be removed and misplaced, or on heavily curved areas where they are likely to peel or wrinkle. The goal is simple: the label should be the first thing someone sees when they reach for the container.

A well-designed label works like a good road sign. It uses clear symbols, high contrast, and simple text to convey critical information instantly, without requiring the user to stop and decipher it.

On-Demand Printing vs Pre-Printed Labels

So, how do you actually produce these labels? Your facility's needs will point you towards one of two main approaches.

On-demand printing gives you the most flexibility. Using a dedicated thermal transfer printer with durable label stock, you can create custom secondary container labels exactly when you need them. This is ideal for labs or sites that handle a wide and ever-changing variety of chemicals.

Alternatively, pre-printed labels can be ordered in bulk, often with standard information already filled in. This can save money if you use huge volumes of the same few chemicals, but it lacks the adaptability needed for unique or rarely used substances. For most modern workplaces, a hybrid approach or a reliable on-demand system offers the best balance of efficiency and compliance.

How Automation Simplifies Label Compliance

Creating and managing secondary container labels by hand is a constant uphill battle. It’s a slow, painstaking process that forces someone to hunt down the right Safety Data Sheet, meticulously copy over product names and hazard warnings, and then physically print and stick each label. This chain of manual steps is an open invitation to costly mistakes, from simple typos to picking the wrong pictograms—errors that can easily lead to compliance fines or, worse, serious safety incidents.

This is exactly where automation changes the game. By moving away from these outdated manual methods, you can build a labelling system that isn't just faster and more efficient, but vastly more accurate and reliable.

Automating Data Extraction from SDS

Modern compliance platforms, like NextSDS, use intelligent technology to completely rethink the process, starting right at the source: the Safety Data Sheet. When a new SDS is uploaded, the system’s AI doesn’t just store the file; it reads and understands it.

The platform automatically pulls out the most critical data points needed for a compliant label. This includes:

- The exact Product Identifier

- All required Hazard and Precautionary Statements

- The correct GHS Pictograms and Signal Word

This single step—automated extraction—eliminates the need for manual data entry, which is where most mistakes happen. Instead of an employee burning valuable time sifting through a 12-page document, the system does the work in seconds. The information is always accurate because it's pulled directly from the source.

The NextSDS dashboard becomes your central hub for managing all chemical safety information.

This interface shows how all essential data, from hazard ratings to regulatory flags, is organised for quick access, forming the foundation for automated label generation.

One-Click Generation of Compliant Labels

Once that data is in the system, generating a fully compliant GHS/CLP secondary container label becomes as simple as clicking a button. The integrated labelling module within NextSDS instantly populates a template with all the mandatory information, formatted correctly and ready for you to print.

This solves one of the biggest headaches for any HSE manager: ensuring every single label is consistent and meets all regulatory standards. There’s no more guesswork. The system guarantees that every label it produces contains the right elements, dramatically cutting down your risk of non-compliance and saving countless hours of administrative work.

Automation transforms label compliance from a reactive, manual chore into a proactive, system-driven process. It ensures consistency, removes the potential for human error, and frees up your safety team to focus on higher-value safety initiatives instead of paperwork.

Solving Real-World Safety Challenges

Beyond just printing standard labels, automation provides powerful tools designed for the modern workplace. NextSDS, for example, can generate mobile safety cards with QR codes. An employee out on the factory floor or at a remote site can just scan the code on a container with their phone. Instantly, they have access to crucial information like required PPE, first-aid measures, and emergency procedures.

This capability is especially vital in regions with fast-moving regulations. Take Belgium, for instance. New EU rules are constantly reshaping chemical handling, and secondary container labels are pivotal for staying compliant. The new PPWR (EU 2025/40), which was published on 22 January 2025 and enters into force on 11 February, replaces the old Directive 94/62/EC. It introduces lifecycle labelling under Article 12, aimed at curbing excessive packaging and boosting recyclability.

Belgium is already an EU leader, boasting 99.1% recovery and 80.0% recycling rates in 2022, so the regional focus on correct labelling for waste streams is intense. For NextSDS clients in procurement and e-commerce, this means AI-flagged SVHCs and auto-generated labels help prevent compliance headaches, particularly since Belgium's PMD recycling system serves 80% of homes. For HSE teams, mobile cards with hazard ratings ensure that chemicals used beyond a single shift are handled correctly, helping to avoid fines in this high-performance region. You can learn more about the EU's new legislation for packaging and packaging waste on sgs.com.

Perhaps one of the most significant benefits of an automated system is how it handles updates. When a manufacturer revises an SDS or regulations change, the system automatically flags the outdated information. Any new labels you print will reflect the latest, most accurate data. This proactive approach keeps your entire chemical inventory compliant without you having to conduct a full manual audit, ensuring your workplace stays safe and ahead of the curve.

Common Labelling Mistakes and How to Avoid Them

Even with a rock-solid safety programme, it’s often the small, everyday habits that can cause the biggest problems. When it comes to secondary container labels, tiny oversights can quickly add up, turning a well-understood chemical into a complete mystery and a serious hazard. Getting a handle on these common slip-ups is the first real step to making your safety system truly reliable.

Most of these mistakes come from the same place: people seeing labelling as a chore to be done later, not as an essential part of the task itself. This attitude is what leads to dangerous shortcuts, which can result in everything from accidental exposure to hefty regulatory fines.

The Pitfall of Illegible Handwritten Labels

We’ve all seen it: a quick scribble with a permanent marker on a bottle. It feels fast, but it’s a huge gamble. These handwritten labels are notoriously fragile. All it takes is a splash of water, a drip of solvent, or even a bit of grease from a glove to turn that vital information into an unreadable smudge.

Suddenly, you have a high-stakes guessing game on your hands. An employee finding an unidentifiable container might handle it incorrectly, mix it with something that causes a dangerous reaction, or apply the wrong first aid in an emergency. The fix is simple but non-negotiable: always use durable, printed labels built to withstand the specific chemicals and conditions of your work environment.

Forgetting to Update Labels After an SDS Revision

A Safety Data Sheet (SDS) isn’t a one-and-done document. Manufacturers update them whenever new hazard information comes to light. A critical failure is letting that new information stop at the SDS file, without ever making it onto your secondary container labels. An old label means your team is operating with outdated—and dangerously incomplete—safety advice.

The only way to prevent this is to tightly connect your SDS management with your labelling process.

When a new SDS version comes in, just filing it isn't enough. Your procedure must automatically trigger a review and re-labelling of every secondary container with that substance. Your hazard information has to be current, always.

The "Just for a Moment" Unlabelled Container

"I'm only using this for a second." It's an excuse we hear all the time for not labelling a container. But that "second" can easily turn into minutes or hours. An unexpected phone call, a fire alarm, or a shift change can leave that anonymous container sitting on a bench for someone else to discover and misuse.

The only truly safe policy is a zero-tolerance one: no chemical is ever transferred to another container without a label, no matter how short its intended use. This simple, firm rule closes the door on human error and ensures safety information is never missing.

In Belgium, a key part of the BE region's chemical safety framework, this is especially critical due to a major push for recycling. The region hit an impressive 88% overall packaging recycling rate in 2023, and that system can't afford to have hazardous materials sneak into the waste stream. An unlabelled spray bottle could easily contaminate a batch of recyclates, a problem known to cause fires and dangerous fumes in facilities across the EU. You can read more about the Benelux packaging market on fachpack.de.

Got Questions About Secondary Labels? We've Got Answers.

When you're dealing with the day-to-day realities of workplace chemical safety, the rules around secondary container labels can get a bit fuzzy. It’s one thing to know the regulations, but it's another to apply them on a busy shop floor. Let's clear up a few of the most common questions we hear.

Do I really need a label if I’m just using it right now?

Ah, the "immediate use" question. The official exemption here is incredibly narrow and, frankly, not a safe bet. While some rules might say it’s okay for an unlabelled container to be used by one person, all within a single work shift, this is a risky habit to get into.

Think about it: what if you get called away for a minute? What if someone else grabs it by mistake? The moment that container is out of your direct control, it must have a secondary container label. European CLP regulations are particularly strict on this. The best practice, and the safest one, is simple: label every container, every time. It just takes a moment and eliminates any chance of a dangerous mix-up.

A core principle of chemical safety is that information must travel with the hazard. Relying on an immediate-use exemption breaks this crucial link and introduces unnecessary risk into your workplace.

Can't we just use a colour-coding system instead of full labels?

No, a colour-coding system on its own, like HMIS or NFPA diamonds, won't cut it for compliance. While those systems are fantastic for giving a quick, at-a-glance idea of the hazards, they are meant to supplement a proper label, not replace it.

A compliant label needs specific, legally required details: the product identifier, the official GHS pictograms, and the full hazard and precautionary statements. A colour-coded sticker simply doesn't contain that level of detail. By all means, use colour codes to support your safety programme, but never as a substitute for a full GHS/CLP label.

What should I do if the original supplier label gets ruined?

A damaged or missing label on a hazardous chemical container is a serious problem—both as a safety risk and a compliance violation. If the original manufacturer's label gets torn, smudged, or becomes illegible for any reason, you need to replace it right away.

Your go-to source for this information is the chemical's Safety Data Sheet (SDS). It has everything you need to create a new, compliant label. This is exactly where having an organised system pays off. If you have a platform managing your SDS library, you can pull up the data instantly and print a perfect replacement label on the spot, ensuring there's never a gap in your safety protocol.

With NextSDS, you can stop the guesswork and create compliant secondary container labels in seconds. Our system pulls the necessary data straight from your SDS library to generate accurate, clear labels, keeping your team protected and your facility compliant. See how you can automate your chemical safety management by visiting the NextSDS website.