A UN number for hazardous materials is a four-digit code, plain and simple. It’s assigned by the United Nations to classify and identify dangerous goods or chemical substances during transport. Think of it as a universal passport for a chemical—a single, unambiguous identifier that tells everyone exactly what they're dealing with, no matter where it is in the world.

The Universal Language of Chemical Safety

Imagine you need to ship a flammable liquid from Belgium to Japan. Locally, it might be called "Flammen-X," but in Japan, it's known as "Moeru-Liquid." Relying on trade names alone is a recipe for disaster. This is where the UN number steps in to cut through the confusion.

It’s a standardised system that works across languages, trade names, and borders. This simple code is the backbone of global safety, ensuring a warehouse operator in Antwerp and a first responder in Tokyo are on the same page about a substance's risks.

This system is the bedrock for compliance with key transport regulations, including:

- ADR: The standard for road transport across Europe.

- RID: The regulations governing rail transport.

- IMDG: The code for international maritime shipping.

By assigning a specific number, like UN 1203 for petrol or UN 1830 for sulphuric acid, the system instantly communicates the primary hazard. This single code dictates everything from the placards on the vehicle to the labels on containers and the emergency actions to take if something goes wrong.

A Foundation for Modern Safety Workflows

The real-world impact of the UN number for hazardous materials is clear. In the BE region alone, we've seen how this system underpins a safer logistics network. Recent data from 9.5 million ADR-compliant hazmat shipments showed that using UN numbers helped slash emergency response times by a massive 65%.

This isn't just a coincidence. The system's success comes from its deep integration into modern safety management. Platforms like NextSDS now automate the extraction and verification of these codes from Safety Data Sheets, catching dangerous errors before a shipment even leaves the warehouse. You can learn more about the regulations driving these safety gains directly from the UNECE.

The UN number is more than just a label; it's the central piece of data that connects a chemical to its entire safety profile. It’s the key that unlocks information on proper handling, storage, and emergency actions, safeguarding people and the environment throughout the supply chain.

How UN Numbers Drive Chemical Safety and Compliance

A UN number isn't just a random code slapped on a barrel. Think of it as a universal passport for hazardous materials. With this single four-digit number, you unlock a treasure trove of critical safety information—from the substance's specific dangers and handling protocols to emergency response plans and correct labelling.

This number is the critical link between a chemical and the entire global safety framework built around it. Without the right UN number, you're essentially flying blind in the complex world of dangerous goods, relying on vague trade names or guesswork. That’s a recipe for disaster.

Decoding Hazards with the Nine Classes

The real power of a UN number comes from its direct connection to the nine internationally recognised hazard classes. Each class sorts substances by their main danger, giving everyone from warehouse staff to emergency responders immediate, clear information. It's a universal language of safety.

Here are the nine major hazard classes:

- Class 1 Explosives

- Class 2 Gases

- Class 3 Flammable Liquids

- Class 4 Flammable Solids

- Class 5 Oxidising Substances and Organic Peroxides

- Class 6 Toxic and Infectious Substances

- Class 7 Radioactive Material

- Class 8 Corrosive Substances

- Class 9 Miscellaneous Dangerous Goods (like lithium batteries)

For instance, when a substance gets assigned UN 1760, it's instantly recognised as a Class 8 Corrosive. This one piece of information sets off a chain of specific rules for everything: the type of packaging needed, the placards on the vehicle, and how it must be stored to avoid contact with materials that could cause a dangerous reaction.

The High Cost of a Simple Mistake

Getting a UN number wrong isn't a minor clerical error; the consequences can be catastrophic, ranging from eye-watering fines to life-threatening accidents. Simply transposing two digits can have a devastating ripple effect. Imagine misidentifying a highly flammable liquid (Class 3) as something less hazardous, leading to it being stored next to a heater or in a poorly ventilated room.

Here’s a real-world scenario that plays out all too often: A shipment is documented with the wrong UN number. Because of that mistake, two incompatible chemicals are loaded onto the same lorry. A container leaks during the journey, the substances mix, and a toxic gas is released, putting the driver and the public at severe risk. When first responders arrive, they look at the incorrect placard and might use water to fight a fire, unintentionally making the chemical reaction worse and turning a small leak into a major disaster.

Getting UN numbers right is absolutely fundamental to meeting a whole host of regulations. This goes beyond just transport rules like ADR and extends to broader OSHA compliance requirements for keeping the workplace safe.

The UN number is your first line of defence in preventing chemical incidents. Its correct application dictates every safety decision that follows, from the type of container used to the emergency plan activated in a crisis. Accuracy isn't just a regulatory box to tick; it's a moral and operational necessity.

In the busy ports of Rotterdam and Antwerp, UN numbers are the unsung heroes of safe transport under the ADR agreement. Back in the 1990s, Europe was seeing around 1,200 serious hazmat road incidents every year. By 2023, that number had dropped to under 450—a massive 62% decrease, thanks in large part to the strict enforcement of UN numbers on transport documents and Safety Data Sheets. For HSE managers, this is a stark reminder of why accurate data matters, especially when fines for non-compliance can hit €150,000 per violation in places like Belgium and the Netherlands. You can learn more about these rules in our guide to ADR transport documentation.

How to Find and Verify the Correct UN Number

Getting the UN number for hazardous materials right isn’t a guessing game. It's the first, most crucial step in ensuring your team is safe and your shipments are compliant. One wrong number can lead to serious incidents, so knowing exactly where to look and how to double-check the information is a non-negotiable part of the job.

Thankfully, there’s a clear path to follow. It all starts with the product’s official biography: the Safety Data Sheet (SDS).

Start with Section 14 of the Safety Data Sheet

The most direct route to finding a UN number is by turning straight to Section 14: Transport Information on the product’s SDS. This part of the document is specifically laid out to give you everything needed to ship the substance safely, whether by road, sea, or air.

When you’re looking at Section 14, you’ll find a cluster of connected information:

- UN Number: The four-digit code, like UN 1993.

- Proper Shipping Name: The official, standardised name that goes with the number.

- Hazard Class: What kind of danger the substance presents (e.g., Class 3 for flammable liquids).

- Packing Group: A Roman numeral—I, II, or III—that tells you the degree of danger.

These four pieces of information are a package deal. The UN number points to a specific proper shipping name and hazard class, and the Packing Group adds critical context on just how severe that hazard is. To get a better handle on this, you can learn more about transport classification in Section 14 of an SDS.

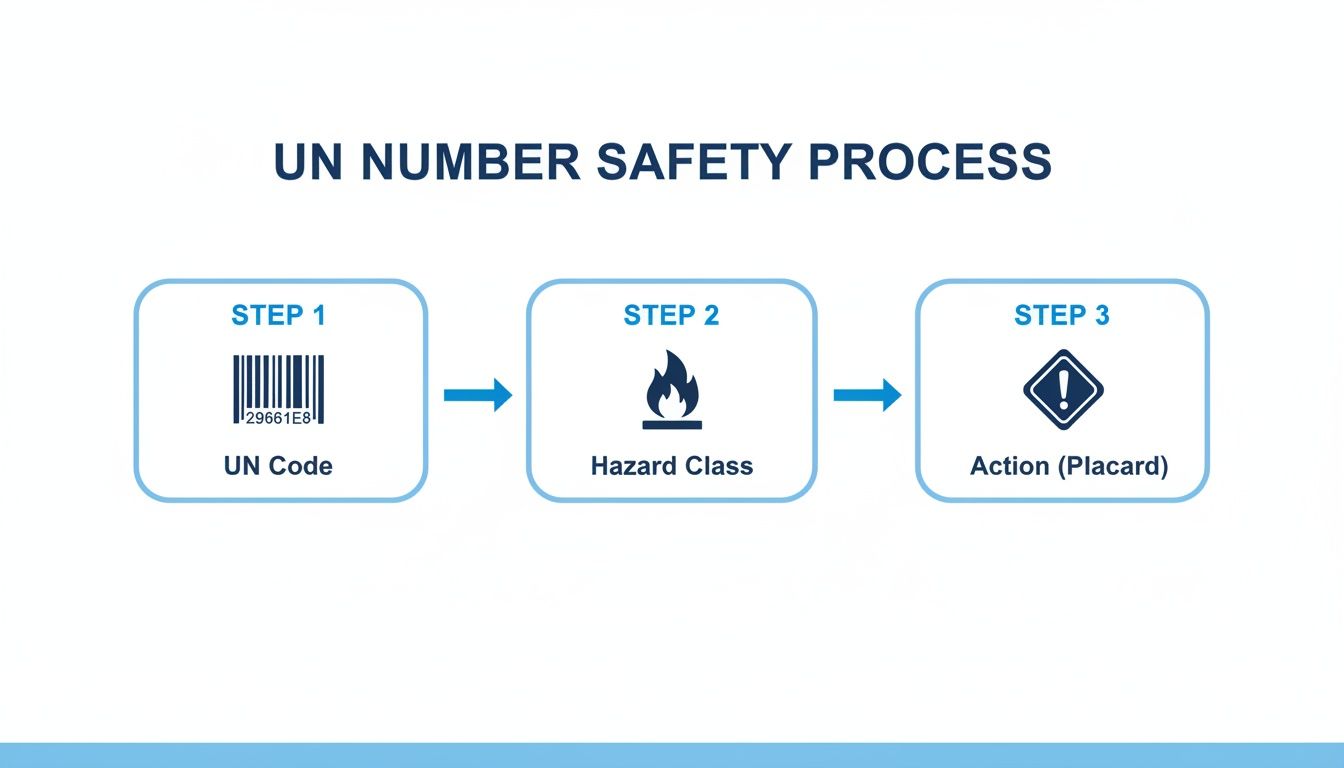

This whole process kicks off a chain reaction of safety measures, as you can see below.

Once you have the right UN number, you know the hazard class, which then dictates the exact placards your vehicle needs. It’s a direct line from identification to action.

Cross-Reference with Official Regulations

The SDS is your go-to starting point, but it shouldn't be your only source. Supplier information can sometimes be outdated, and honest mistakes do happen. That’s why a robust compliance programme always includes verifying the UN number against official regulatory sources.

Think of it as getting a second opinion from a specialist. The ultimate authority is the UNECE ‘Orange Book’, which is the foundational text for nearly all dangerous goods regulations worldwide.

From there, you’ll want to check the rules for your specific mode of transport:

- IATA Dangerous Goods Regulations (DGR) for air.

- ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) for road transport in Europe.

- IMDG (International Maritime Dangerous Goods) Code for sea.

Verifying a UN number is a simple two-step process: find it on the SDS, then confirm it in the official rulebook for your transport mode. This vital check ensures you're not relying on a single, potentially flawed, piece of information.

The Role of Packing Groups in Verification

Don’t overlook the Packing Group (PG). This little Roman numeral is a huge piece of the puzzle because it tells you how dangerous a substance is within its class. This can sometimes be the deciding factor in which UN number is assigned, especially for those generic “N.O.S.” (Not Otherwise Specified) entries.

The breakdown is simple:

- PG I: High danger

- PG II: Medium danger

- PG III: Low danger

For instance, you might have two flammable liquids that are both in Hazard Class 3. But if one is PG I and the other is PG III, they will have completely different requirements for packaging, handling, and segregation. When you’re verifying a UN number, make sure the Packing Group listed on the SDS makes sense for the chemical and matches what you see in the official regulations. It’s the final check that confirms the level of risk has been properly evaluated.

For HSE and procurement teams, having a structured approach to this verification is key. This simple checklist can help guide you through the process, from the supplier's document to the official regulations.

UN Number Source Verification Checklist

| Information Source | What to Look For | Key Verification Step | NextSDS Automation |

|---|---|---|---|

| Safety Data Sheet (Section 14) | UN number, Proper Shipping Name, Hazard Class, Packing Group (I, II, or III). | Confirm all four elements are present and consistent with each other. | Automatically extracts and flags missing or conflicting transport data. |

| Official Regulations (IATA, ADR, IMDG) | Match the substance's name or UN number in the official dangerous goods list. | Check that the hazard class, packing group, and any special provisions align with the SDS. | Screens extracted UN numbers against global regulatory lists for all transport modes. |

| Chemical Properties (Section 9) | Check physical data like flash point or toxicity values. | Ensure the assigned Packing Group logically follows from the substance's inherent properties. | Cross-references physical properties to flag potential PG misclassifications. |

| Manufacturer/Supplier Contact | Direct confirmation of transport classification details. | If discrepancies exist, contact the supplier directly for clarification and an updated SDS. | Manages supplier communication and tracks SDS version updates. |

This systematic check, moving from the provided SDS to official regulatory confirmation, builds a powerful layer of safety and ensures you're never caught out by an error.

Common Mistakes When Using UN Numbers

Even with the best of intentions, getting the UN number for hazardous materials wrong happens more often than you'd think. These aren't just small clerical errors. They're cracks in your safety and compliance foundation that can lead to hefty fines, rejected shipments, and genuinely dangerous situations for handlers and first responders. The first step to building a more resilient safety programme is knowing where things typically go wrong.

A classic mistake is misusing "Not Otherwise Specified" or N.O.S. entries. These are catch-all UN numbers, like UN 1993 for Flammable Liquid, N.O.S., meant for mixtures or substances that don't have their own specific entry in the dangerous goods regulations. The problem arises when teams use this as a convenient shortcut without doing the proper homework.

Using an N.O.S. number isn't a free pass; you're required to list the technical names of the hazardous components in the documentation. Forgetting this critical step renders the classification incomplete and non-compliant, leaving emergency responders completely in the dark if something goes wrong.

Overlooking Physical State and Concentration

Another major pitfall is picking a UN number based on a chemical's name alone, completely ignoring its physical state or concentration. It's a crucial detail because a substance can have entirely different UN numbers depending on whether it's a solid, liquid, or gas, or if its concentration tips it over a specific regulatory line.

Why does this matter so much? Because the physical state dramatically changes how a substance behaves and the risks it presents. For instance, a chemical might be classified under one UN number as a solid but need a completely different one as a liquid because its flashpoint and vapour pressure are worlds apart. Getting it wrong means you could be using the wrong packaging, giving incorrect handling advice, and working from a fundamentally flawed risk assessment.

"The most dangerous assumption in hazmat logistics is that a chemical's name tells the whole story. Its physical state, concentration, and purity are often the details that determine its true hazard classification and, consequently, its correct UN number."

Failing to account for these variables is like using a street map of London to navigate the entire UK—you might have the right starting point, but you’re missing all the critical detail needed for a safe journey.

Choosing a Generic Instead of a Specific Number

The regulations are built on a simple principle: be specific. If a UN number exists for a particular substance, you must use it. Reaching for a more general or N.O.S. entry when a precise one is available isn't just bad practice; it's a straight-up compliance violation. This usually happens out of habit, convenience, or a simple lack of thorough research.

Think about this common scenario:

- A team needs to ship a specific type of alcohol, which has its own dedicated UN number.

- Instead of checking the dangerous goods list for that exact substance, they just grab a generic "Flammable Liquid" UN number.

- This generic code might not trigger the specific handling precautions, storage incompatibilities, or emergency response guidance that the correct, specific number would.

This tiny shortcut can have massive consequences, potentially leading to incompatible chemicals being stored next to each other or emergency crews using the wrong type of agent to fight a fire.

Actionable Strategies to Avoid These Errors

Preventing these mistakes isn't about hoping for the best; it's about having a system. Building a solid compliance process means putting clear checks in place that catch errors before they become incidents.

Here are three practical strategies you can implement right away:

- Centralise Your SDS Management: Ditch the scattered paper binders and messy shared drives. A central, digital system ensures everyone is working from the latest version of a Safety Data Sheet, killing the risk of using outdated transport information.

- Establish a Routine Audit Process: Make it a habit to regularly check your chemical inventory against your SDS library and shipping documents. This proactive check-up helps you spot discrepancies, misclassifications, or missing data long before a shipment is ready to go.

- Build Verification into Procurement: The best time to catch an error is before a hazardous material even arrives on site. Make UN number verification a mandatory step in your procurement workflow. That way, you ensure new chemicals are properly classified from day one.

Automating UN Number Management for Your Business

Trying to manage UN numbers manually is a high-stakes, thankless job. It means your team is constantly digging through Safety Data Sheets, poring over dense regulatory manuals, and trying to keep track of every little update across road, sea, and air transport rules. It’s not just inefficient; it's a process practically designed for human error. A single mistake can lead to rejected shipments, hefty fines, or worse, a serious safety incident.

The thing is, these regulations never sit still. They change. A chemical that was perfectly fine to ship yesterday might have new restrictions today. Staying on top of it all demands constant vigilance, turning a critical safety task into a massive administrative headache. This is exactly where modern, automated systems come in, helping to turn this complex challenge into a clear, reliable process.

Shifting from Manual Checks to Intelligent Automation

Think of a system that acts like an expert compliance partner, working 24/7 to make sure every detail is correct. That's what a platform like NextSDS is designed to do. Instead of someone physically reading a PDF, AI-powered tech automatically scans and pulls out the crucial data points from supplier SDSs the second they come in.

It instantly identifies and captures the essentials:

- UN Number

- Proper Shipping Name

- Hazard Class

- Packing Group

But this isn't just about grabbing data—it's about putting that data to work. The system organises everything into a structured, searchable digital library of all your chemical transport information. This gets rid of the risks that come with old paper binders or chaotic shared drives and sets you up for a smarter, safer way of working.

The platform also keeps an eye on regulatory changes, sending out real-time alerts so your team is always one step ahead. This kind of dashboard gives safety managers an immediate, at-a-glance overview of their compliance status, showing exactly which substances are affected by new or updated rules.

Integrating Compliance into Your Core Operations

Real safety isn't just about having the right paperwork; it's about building compliance checks directly into your daily operations. An automated system makes this happen by connecting UN number management straight to your procurement and operational teams.

For example, when someone wants to buy a new chemical, the system can screen its SDS against global transport regulations like ADR and IATA. If the substance doesn't comply or needs special handling your facility can't provide, it can automatically flag or even block the order. It’s a proactive approach that stops problems before they ever arrive at your site.

By integrating UN number verification directly into the procurement workflow, you shift compliance from a reactive, post-purchase headache to a proactive, preventative strategy. It’s the single most effective way to ensure only safe and compliant materials make it through your doors.

Take a look at Belgium's chemical heartland—Flanders, home to giants like BASF and Solvay. Here, UN numbers aren't just codes; they're statistical lifelines. With Europe's hazmat road transport hitting 150 billion km in 2022, Belgium's 8.5 billion km share shows just how much is at stake. Automation here validates supplier SDSs against UNECE databases and auto-generates GHS/CLP labels with QR-linked UN details for PPE and separation distances. This is a crucial function when 22% of local incidents are caused by improper storage. For procurement teams, it means screening for Substances of Very High Concern (SVHCs) tied to specific UNs, helping avoid REACH fines that average €75,000. You can find more insights on the importance of the UN number at sdsmanager.com.

Empowering Your Entire Team with Actionable Data

At the end of the day, safety comes down to the people handling the materials. An automated system gives your entire workforce the tools they need by translating complex regulatory data into clear, easy-to-understand guidance.

With an automated SDS intake system, new and updated documents are processed in a flash. This information is then used to generate mobile-ready safety cards. A warehouse operator can simply scan a QR code on a container to get instant, UN-specific guidance on their phone, from PPE requirements to emergency procedures. It’s how you turn a complex compliance burden into a seamless, reliable, and deeply integrated safety process.

Your Actionable Workflow for UN Number Compliance

Alright, let's move from theory to practice. Knowing what a UN number is is one thing, but building a reliable system to manage them is where the real work—and the real value—lies. Think of this less as a bureaucratic chore and more as a smart business process. A solid workflow protects your people, your reputation, and your bottom line by catching costly errors before they halt a shipment.

We're going to break this down into four straightforward stages. Following this plan will help any safety or logistics manager turn a daunting regulatory demand into a systematic, repeatable operation that actually works.

Step 1: Centralise Your Safety Data Sheets

First things first: you need a single source of truth. If your Safety Data Sheets (SDSs) are stuffed in various binders or scattered across different network drives, you’re setting yourself up for failure. That’s where the risk starts.

Your first move is to get every SDS into one central digital library. This simple action ensures everyone—from the warehouse team to the procurement office—is looking at the same up-to-date document. No more version control headaches. This is the bedrock of effective chemical safety in the workplace.

Step 2: Automate Data Extraction and Validation

Once your library is in order, it's time to bring in some technology. Manually combing through every SDS for transport data is not just slow; it's a recipe for human error. An automated system can do the heavy lifting, scanning each document as it comes in and pulling out the critical data from Section 14.

The system should grab and check these key pieces of information:

- The four-digit UN Number

- The official Proper Shipping Name

- The correct Hazard Class

- The assigned Packing Group (I, II, or III)

Automation takes this from a mind-numbing manual task to a fast, accurate process. More importantly, it flags any missing or dodgy information long before it can cause a real problem.

A proactive compliance workflow isn’t about catching mistakes after they happen. It’s about building a system that prevents them from occurring in the first place, with technology acting as your first line of defence.

Step 3: Integrate Verification into Procurement

The best time to get compliance right is before a hazardous material even arrives at your door. Build UN number verification directly into your purchasing process. When someone requests a new chemical, your system should automatically check its SDS against the latest transport regulations.

This pre-purchase check acts as a crucial gatekeeper. It confirms the material is classified correctly and, just as importantly, that you actually have the right procedures and equipment to handle it safely. You're vetting materials for compliance before you've spent a penny on them.

Step 4: Empower Your Frontline Workers

Finally, get this vital information into the hands of the people who need it most. The folks on the warehouse floor and in the loading bay need immediate, clear guidance. You can use the centralised data to generate simple, mobile-friendly safety cards or even stick QR codes on containers.

A quick scan could pull up exactly what they need to know: proper handling instructions, required PPE, and what to do in an emergency, all tied directly to that specific UN number. This last step closes the loop, turning abstract data into actionable, life-saving information that’s part of your team's daily routine.

Got Questions About UN Numbers? We’ve Got Answers.

When you're dealing with hazardous materials day in and day out, questions are bound to pop up. Even if you've got the basics down, some of the finer points can be tricky. This FAQ section is here to give you quick, straightforward answers to the most common queries we hear about the UN number for hazardous materials.

Think of this as a practical cheat sheet to help you cut through the technical jargon and handle your daily tasks with more confidence.

What’s the Difference Between a UN Number and a CAS Number?

This is a classic point of confusion, but the distinction is actually quite simple once you get it. A UN Number is all about transport classification—it tells you what hazards a substance presents while it’s on the move. On the other hand, a CAS (Chemical Abstracts Service) Number is a unique ID for a specific chemical substance, no matter what it's being used for.

Here’s an easy way to remember it:

- A UN Number is like a warning sign on a lorry. It flags the type of danger inside for shipping (e.g., UN 1203 for petrol).

- A CAS Number is like a chemical's national insurance number. It's a unique identifier for that specific substance (e.g., 71-43-2 for Benzene).

So, while one UN number might cover a whole group of chemicals with similar transport risks, a CAS number always points to just one substance.

Does Every Hazardous Material Have a UN Number?

Not necessarily. Almost any substance that’s officially classified as dangerous for transport will have a UN number. But here's the catch: some materials that are considered hazardous in the workplace under GHS or CLP regulations don't actually meet the criteria to be labelled as dangerous goods for transport.

For instance, a product that is only a mild skin irritant (a GHS hazard) might not be regulated for road or sea freight. If that's the case, it won't have a UN number. The definitive answer is always waiting for you in Section 14 of the Safety Data Sheet, which will clearly state if the product is not regulated for transport.

If Section 14 of an SDS is blank or says "not regulated," you can be sure the material doesn't have a UN number for transport. This is a vital check. Assuming a product is non-hazardous without looking it up can lead to some serious compliance headaches.

Can One Chemical Have More Than One UN Number?

Absolutely. This happens more often than you might think, and it usually comes down to the material's physical state, its concentration, or the specific hazard it poses in different situations. For example, a substance could have one UN number when it's a solid and a completely different one when it's a liquid or dissolved in a solvent.

The key takeaway is that the correct un number for hazardous materials must always match the exact form of the chemical you're actually shipping.

Keeping track of UN numbers and staying on top of transport compliance is a massive job with zero room for error. NextSDS takes the manual cross-checking and regulatory guesswork off your plate with a smart, automated platform. Our system pulls UN numbers directly from your SDSs, checks them against the latest global regulations, and builds compliance checks right into your procurement workflow—stopping risks before they even get through the door. Discover how NextSDS can simplify your chemical safety management.