Let's get straight to the point: SDS stands for Safety Data Sheet. Think of it as the complete biography for a chemical product. It tells you everything you need to know—its properties, the risks it poses, and exactly how to handle it safely.

What's the Real Purpose of a Safety Data Sheet?

At its core, a Safety Data Sheet is a legally required document that chemical manufacturers and suppliers must provide for any hazardous material they sell. It's the central pillar of chemical safety in any workplace, mandated by the Occupational Safety and Health Administration (OSHA) to protect workers.

The primary goal here is clear communication. An SDS translates complex chemical data into practical, understandable information, ensuring everyone from lab technicians to warehouse staff and first responders knows what they're dealing with.

Imagine trying to assemble a piece of furniture without the instructions. You might get it right, but you could also end up with a wobbly table—or worse, an injury. An SDS is that essential instruction manual for chemicals. It closes the knowledge gap between the people who make the chemical and the people who use it.

This document is far from just a piece of compliance paperwork; it’s a critical tool for everyday risk management. It gives you the full picture on:

- The specific hazards of a chemical, from flammability to long-term health effects.

- Proper procedures for handling, storage, and disposal.

- First-aid measures to take if someone is accidentally exposed.

- The personal protective equipment (PPE) you need, like specific gloves or respirators.

Basically, an SDS turns technical jargon into actionable safety guidance, forming the bedrock of any solid workplace safety program.

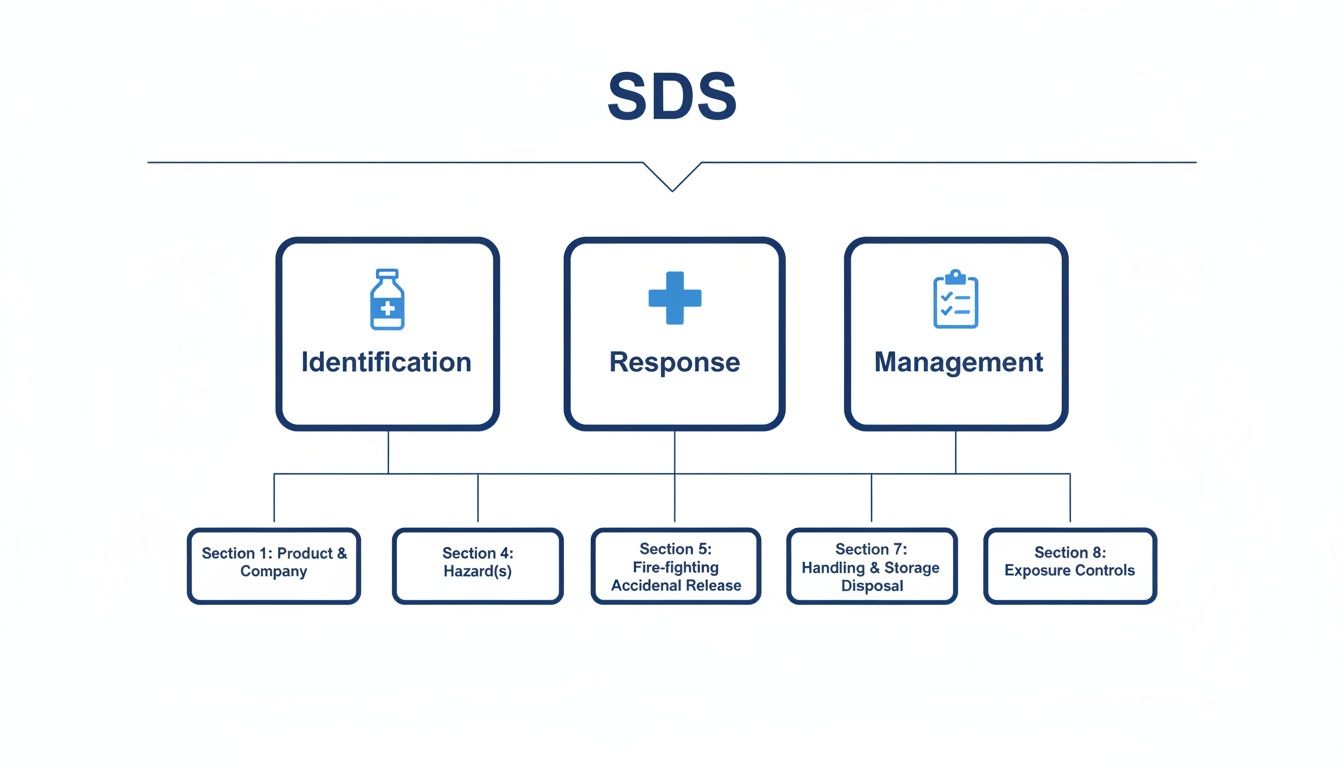

To put it simply, here’s a quick breakdown of what a Safety Data Sheet is designed to do.

Safety Data Sheet At a Glance

| Component | Description |

|---|---|

| What is it? | A standardized, 16-section document providing detailed health and safety information about a hazardous chemical. |

| Who provides it? | The chemical manufacturer, distributor, or importer is legally required to provide it. |

| Who needs it? | Employers, employees, and emergency responders who handle or may be exposed to the chemical. |

| Why is it important? | It ensures everyone understands a chemical's risks and knows how to work with it safely, preventing accidents and injuries. |

Ultimately, the SDS empowers your team with the knowledge they need to make safe decisions on the job.

From MSDS to SDS: A Huge Leap for Safety

If you’ve been around industrial workplaces for a while, the term MSDS probably sounds familiar. It stands for Material Safety Data Sheet, and for years, it was the go-to document for chemical safety. But the move to the modern SDS was far more than a name change—it was a critical step in making workplaces safer around the globe.

The old MSDS system had a major flaw: a complete lack of consistency. One manufacturer’s sheet might have eight sections, while another used a totally different format. This forced workers to hunt for crucial information like first-aid instructions or what PPE to wear. In an emergency, that wasted time could be disastrous.

Everything changed with the adoption of the Globally Harmonized System (GHS) for classifying and labeling chemicals. In 2012, OSHA updated its Hazard Communication Standard to align with GHS, officially beginning the phase-out of the old MSDS and ushering in the standardized SDS we use today.

Why Standardization Was a Game-Changer

The single biggest difference between an old MSDS and a modern SDS is the structure. GHS introduced a mandatory, user-friendly 16-section format that every chemical manufacturer must now follow.

This global standard means critical safety information is always in the same place, no matter who made the chemical or where it was produced. It’s completely predictable.

- Need to know the hazards? Go straight to Section 2.

- Looking for first-aid measures? They're always in Section 4.

- Figuring out exposure controls and personal protection? That's Section 8.

This consistent structure creates a universal language for chemical safety. A worker in Texas can instantly understand a document from Germany, and vice versa. It removes the guesswork and allows for faster, smarter responses to chemical hazards.

Ultimately, this evolution was about making safety information accessible and reliable. By standardizing the format, the SDS became a much more powerful tool, ensuring that employees and emergency responders can find life-saving data in seconds—every single time.

A Guided Tour of the 16 SDS Sections

At first glance, a Safety Data Sheet can feel overwhelming. It's dense, technical, and packed with information. But once you understand its layout, you'll see it’s actually a highly organized and predictable document. The genius of the SDS is its universal 16-section structure, designed to give you the exact information you need, right when you need it.

Think of it less like a dry manual and more like a chemical safety roadmap. Sections 1-8 are your go-to for immediate action—what you need to know for daily handling and emergencies. The later sections, 9-11 and 16, dive deep into the technical details for specialists, while 12-15 cover the logistics of transport, disposal, and other regulations.

This structure isn't random. It's designed to prioritize information, moving logically from quick identification to emergency response, and finally to long-term management.

As the diagram shows, the layout groups information into intuitive buckets, so you’re never scrambling to find what you need in a crisis.

Your Quick Reference Guide

The first few sections are all about rapid assessment. This is where you'll find the answers to your most urgent questions, fast.

Section 1 Identification: This tells you exactly what the chemical is and who to call if something goes wrong. It lists the product name, its intended uses, and the supplier's emergency contact information.

Section 2 Hazard Identification: This is your at-a-glance hazard summary. It uses standardized pictograms, signal words like "Danger" or "Warning," and clear hazard statements to communicate the primary risks visually and quickly.

Section 4 First-Aid Measures: Consider this your emergency playbook. It lays out the critical steps to take for exposure—whether through skin contact, inhalation, or ingestion—providing life-saving guidance for first responders and anyone on-site.

The Detailed Safety Blueprint

Once you've grasped the immediate risks, the next set of sections provides the nitty-gritty details for safe handling and daily operations.

These sections are the backbone of your workplace safety protocols. They empower you to move beyond simply knowing a chemical is hazardous to understanding precisely how to control those hazards.

This is where you'll find your personal protective equipment (PPE) requirements. Section 8 Exposure Controls/Personal Protection is one of the most vital and frequently referenced parts of any SDS. It specifies the exact PPE needed, such as the right type of gloves, safety glasses, or respirators. It also provides crucial exposure limits, like Occupational Exposure Limits (OELs), which are essential for monitoring and maintaining a safe work environment.

Decoding Key Information in an SDS

To help you navigate, this table breaks down some of the most critical sections you'll rely on for day-to-day safety and emergency response.

| Section Number & Title | What You Will Find Inside | Why This Information Is Critical |

|---|---|---|

| Section 2: Hazard Identification | Pictograms, signal words ("Danger," "Warning"), and hazard statements. | Provides an immediate visual summary of the chemical's primary risks. |

| Section 4: First-Aid Measures | Step-by-step instructions for exposure via inhalation, skin/eye contact, or ingestion. | Acts as a critical guide for first responders and employees during an emergency. |

| Section 5: Fire-Fighting Measures | Suitable extinguishing agents (e.g., foam, CO2) and specific hazards from a fire. | Ensures firefighters use the correct methods and avoid making a bad situation worse. |

| Section 6: Accidental Release Measures | Procedures for containment, cleanup, and personal precautions for spills or leaks. | Helps minimize environmental contamination and protects cleanup crews. |

| Section 7: Handling and Storage | Guidelines for safe handling practices and proper storage conditions (e.g., temperature, ventilation). | Prevents accidents by addressing risks before they happen. |

| Section 8: Exposure Controls/PPE | Required Personal Protective Equipment (PPE) and Occupational Exposure Limits (OELs). | The core of worker protection—it tells you exactly what gear is needed to handle the chemical safely. |

This detailed breakdown is what transforms a regulatory document into a powerful, practical tool. It turns compliance into an actionable strategy for protecting your team, ensuring that no matter the substance, you can find the life-saving information you need in seconds.

How an SDS Functions in Your Daily Operations

A Safety Data Sheet is much more than a compliance document you file away just in case of an audit. It’s an active, operational tool that weaves directly into your organization’s daily workflows, acting as a crucial link between procurement, safety, and emergency response.

Think of it less as a static file and more as a dynamic playbook. Different teams will use it for distinct, critical purposes from the moment a chemical is considered for purchase.

The document's journey actually starts long before a chemical ever arrives on-site. The procurement department uses the SDS as a primary screening tool. Before they even think about placing an order, they can review Section 2 (Hazard Identification) and Section 15 (Regulatory Information) to vet new substances against company safety policies or restricted chemical lists. This simple, proactive check is a powerful way to keep particularly nasty materials from ever entering the workplace.

From Receiving Dock to Emergency Response

Once a chemical is approved and shows up at your door, the SDS becomes the go-to guide for your logistics and operations staff. They rely on it for the clear, practical instructions that keep everyone safe and prevent costly incidents.

- Safe Storage: Section 7 (Handling and Storage) gives explicit instructions on where and how to store the chemical. It covers everything from temperature controls and ventilation requirements to which other chemicals it absolutely cannot be stored near. This is what prevents dangerous reactions.

- Worker Protection: Section 8 (Exposure Controls/PPE) dictates the exact Personal Protective Equipment (PPE) needed for handling the substance. We're talking specifics, like what kind of gloves to wear or which type of respirator is required. This information is gold for training and daily task assignments.

- Emergency Blueprint: When a crisis hits—like a spill or an accidental exposure—the SDS is the single source of truth for first responders. Sections 4, 5, and 6 provide immediate, life-saving instructions on first aid, firefighting measures, and how to contain an accidental release.

An SDS transforms abstract chemical data into clear, actionable steps for every stage of a product's lifecycle within your facility. It empowers every team member to make informed decisions, ensuring safety is embedded in every process.

The growing recognition of this document's importance is mirrored in the market for managing them. The global Safety Data Sheet management market was valued at USD 2.7 billion in 2024, a number that shows just how seriously industries are taking chemical safety. You can find more details on this industry growth in a report from DataHorizzon Research.

By understanding how an SDS functions operationally, you can see its true value—it's far more than just a way to check a regulatory box.

Making Compliance Easier with Modern SDS Management

If you're still managing chemical safety with dusty three-ring binders or a messy shared drive, you know the struggle. Finding the right information in an emergency is nearly impossible, and just keeping up with revisions and regulations feels like a full-time job. It’s a reactive, paper-chasing approach that creates compliance gaps and puts your team at risk.

Thankfully, we've moved past that. Modern SDS management platforms can turn that chaotic process into a streamlined, proactive safety strategy. Imagine having a single, centralized library for every chemical at your facility, accessible in seconds.

The industry is clearly moving in this direction. The global market for these digital compliance tools was valued at USD 2.5 billion in 2024, a number that speaks volumes about the shift away from old-school methods. You can dive deeper into these market trends with this report from Data Insights Market.

Leave the Manual Updates Behind

One of the biggest wins with modern software is automation. These platforms do the legwork for you, automatically pulling the latest SDS versions directly from manufacturers. That means you're never caught using an outdated sheet with the wrong hazard data or PPE guidance.

Think about what that frees you up to do. Instead of spending hours on administrative busywork, you can focus on what actually keeps people safe: implementing safety protocols, running training, and being present on the floor.

Advanced systems, like NextSDS, take it a step further with real-time screening. They can cross-reference your entire chemical inventory against global regulatory watchlists, instantly flagging any substance that's restricted or needs special handling protocols. This gives your procurement team the power to make smarter, safer buys before a problem chemical even makes it through your doors.

Here’s a look at what a typical dashboard in one of these systems looks like—clean, organized, and built for quick access.

The simple layout lets you search, view, and manage your entire chemical library from one screen. It transforms compliance from a headache into a simple, efficient part of your daily workflow.

Got Questions About Safety Data Sheets? We’ve Got Answers.

Even after you get the basics down, real-world questions about Safety Data Sheets always pop up. Let's tackle some of the most common ones that people ask about updates, storage, and day-to-day use.

How Often Should an SDS Be Updated?

Chemical manufacturers have a clear deadline: they must update an SDS within three months of learning any significant new information about a product's hazards or the best ways to protect against them. As an employer, your job is to make sure you always have the most current version they send you.

A really smart move is to do an annual check-up on your entire SDS library. It’s a great way to proactively hunt for any new revisions from your suppliers before they become a problem.

Do We Really Need an SDS for Windex?

This is a classic "it depends" situation. If someone on your team is using a common household cleaner the same way you would at home—a quick spray and wipe—then an SDS generally isn't required.

But, if your business uses that same product in massive quantities or for hours on end, OSHA’s Hazard Communication Standard comes into play. In that scenario, it's treated like any other industrial chemical, and you absolutely must have an SDS on hand and accessible to your employees.

The key is how the product is used. Commercial-level use of a consumer product triggers OSHA's rules, making an SDS a non-negotiable requirement.

What's the Right Way to Store and Access SDSs?

OSHA’s rule is simple in theory: SDSs must be "readily accessible" to every employee during their work shift. No hoops to jump through, no locked doors. How you achieve that is flexible.

- Physical Binders: The old-school method still works. A well-organized binder in a central, easy-to-find spot is a perfectly valid approach.

- Digital Systems: Going digital with a database is powerful, but there's a catch. Everyone has to be trained to find what they need in seconds. You also need a solid backup plan for when the power goes out or the network crashes.

The challenge of keeping up is a big reason why the SDS management market was valued at a whopping USD 1.5 billion in 2024 and is expected to hit USD 3.2 billion by 2033. You can dig into more of the numbers behind this trend on Verified Market Reports. For many companies, modern digital systems are quickly becoming the only practical way to guarantee instant, reliable access.

Managing chemical safety doesn't have to be a constant headache. With a tool like NextSDS, you can finally ditch the dusty binders and clunky spreadsheets. An automated platform puts everything in one place, ensuring your team is always protected and your business stays compliant. See how NextSDS can simplify your safety program.