When you hear the term “acute toxicity,” think immediate impact. It’s the harm a substance can cause right after a single, short-term exposure—usually within 24 hours or less. This isn't about health problems that might creep up over years; it’s the fast-acting, often severe, reaction to a chemical hazard.

Understanding Acute Toxicity in the Workplace

In any conversation about workplace safety, we have to know what kind of chemical hazards we're up against. Acute toxicity is a cornerstone of that understanding because it focuses squarely on the immediate dangers, helping safety managers and procurement teams make decisions that prevent real, preventable harm.

To really get it, let's draw a clear line between two critical concepts:

- Acute Toxicity: This is about the adverse effects that pop up shortly after a single dose or a few doses of a substance within a 24-hour window. The effects are typically sudden and serious.

- Chronic Toxicity: This describes the damage that comes from repeated, long-term exposure over weeks, months, or even years. These issues tend to develop gradually and might not be obvious at first.

The Real-World Impact of Acute Exposure

The dangers of acute toxicity are far from theoretical. Acute poisoning is a major global health problem and a common reason for emergency room visits. The World Health Organization has reported that it leads to around one million illnesses worldwide and carries a sobering 20% fatality rate.

These numbers hammer home why identifying and controlling these hazards is an absolute must for any solid safety program. An accidental splash, a sudden vapor release, or swallowing a contaminated substance can have immediate, life-threatening results. Understanding what acute toxicity means is the first step in building a proactive safety culture.

It’s easy to fall into the trap of thinking "less toxic" means "safe." But even substances with low acute toxicity can pose serious chronic health risks or other physical dangers. A comprehensive approach to chemical safety in the workplace means looking at the full spectrum of hazards listed on the Safety Data Sheet (SDS).

Why This Concept Matters for Your Team

For any team that handles chemicals, getting a grip on acute toxicity is non-negotiable. This knowledge directly influences everything from choosing the right personal protective equipment (PPE) to creating an effective emergency response plan. Without it, your team is flying blind.

When you clearly define what acute toxicity is and show how it differs from chronic exposure, you give your employees the power to spot risks instantly. This foundational knowledge helps them read hazard labels correctly, handle materials with confidence, and react the right way in an emergency—all of which creates a safer workplace for everyone.

How We Measure a Chemical's Immediate Danger

If you can't measure a hazard, you can't manage it. When we talk about a chemical's immediate, short-term danger—its acute toxicity—we rely on specific, standardized numbers to get a clear picture of the risk. These metrics are the bedrock of chemical safety, telling us exactly how dangerous a substance is at first contact.

The whole idea boils down to a concept you already know: the dose-response relationship. Think about it like this: one cup of coffee might wake you up, but chugging ten cups in a row could land you in the hospital. The amount you take in—the dose—determines the body's reaction. Toxicologists apply this same principle, testing substances to find the precise dose that becomes lethal.

What Do LD50 and LC50 Really Mean?

You'll constantly see two terms pop up when measuring acute toxicity: LD50 and LC50. They might sound like technical jargon, but they’re actually the gold standard for measuring how lethal a chemical is.

LD50 (Lethal Dose, 50%): This is the dose of a substance, given all at once, that is calculated to kill 50% of a group of test animals. It’s typically measured in milligrams of the substance per kilogram of body weight (mg/kg).

LC50 (Lethal Concentration, 50%): This is for things you can breathe in—gases, vapors, dusts. It’s the concentration of the chemical in the air that’s expected to kill 50% of test animals during a specific time, usually four hours. You’ll see it expressed in parts per million (ppm) or milligrams per liter (mg/L).

Here’s the single most important thing to remember: the lower the LD50 or LC50 value, the more toxic the substance is. A chemical with a tiny LD50 number is incredibly potent, meaning even a small amount can be fatal.

For instance, let's compare two chemicals. Substance A has an LD50 of 5 mg/kg, while Substance B has an LD50 of 500 mg/kg. Substance A is 100 times more toxic. That simple number tells you it poses a far greater immediate risk, and that’s a crucial piece of information for any risk assessment.

Why the Route of Exposure is Everything

How a chemical gets into your body—the route of exposure—can make all the difference. A substance that’s mostly harmless when spilled on your skin could be deadly if you accidentally swallow it. That’s why LD50 and LC50 values are always linked to a specific way a person can be exposed.

The three main routes of exposure are:

- Oral (Ingestion): Swallowing the substance, letting it enter through your digestive tract.

- Dermal (Skin Contact): Absorbing the substance directly through your skin.

- Inhalation: Breathing in the substance as a gas, vapor, dust, or mist.

When you look at a Safety Data Sheet (SDS), you won’t just see one LD50 value. You'll see separate numbers for oral and dermal exposure. The LD50 (oral) for a chemical might be very low, while its LD50 (dermal) is quite high. This tells you it’s much more dangerous to ingest than to simply touch.

This kind of detail is what separates guesswork from true workplace safety. Knowing a chemical’s toxicity for each exposure route helps you choose the right personal protective equipment (PPE). If the dermal LD50 is low, chemical-resistant gloves and clothing are a must. If its inhalation LC50 is low, you absolutely need proper respiratory protection. It’s a data-driven approach that ensures you’re protected from the specific ways a chemical can hurt you.

Translating GHS Hazard Labels into Action

So, you have the numbers—the LD50 and LC50 values that tell you how toxic a chemical is. But how does that data translate from a lab report into a clear, immediate warning you can understand on the factory floor or in the lab? That's where the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) comes in.

Think of GHS as the universal language for chemical safety. It was created to make hazard information consistent and easy to understand, no matter where you are in the world. In Europe, you'll see it implemented as the Classification, Labelling and Packaging (CLP) Regulation. Both systems use the same toolkit—categories, pictograms, and signal words—to turn complex data into simple, actionable safety cues right on the label.

Decoding GHS Acute Toxicity Categories

Under GHS, acute toxicity is sorted into five categories. It’s a simple system: Category 1 is the most deadly, while Category 5 is the least hazardous. Each category is tied directly to a specific range of LD50 or LC50 values.

The key takeaway? A lower category number means a much higher danger level. A chemical that falls into Category 1 could be fatal after even a tiny exposure and requires a completely different level of respect—and personal protective equipment (PPE)—than a substance in Category 4. Knowing this hierarchy is fundamental to assessing risk at a glance.

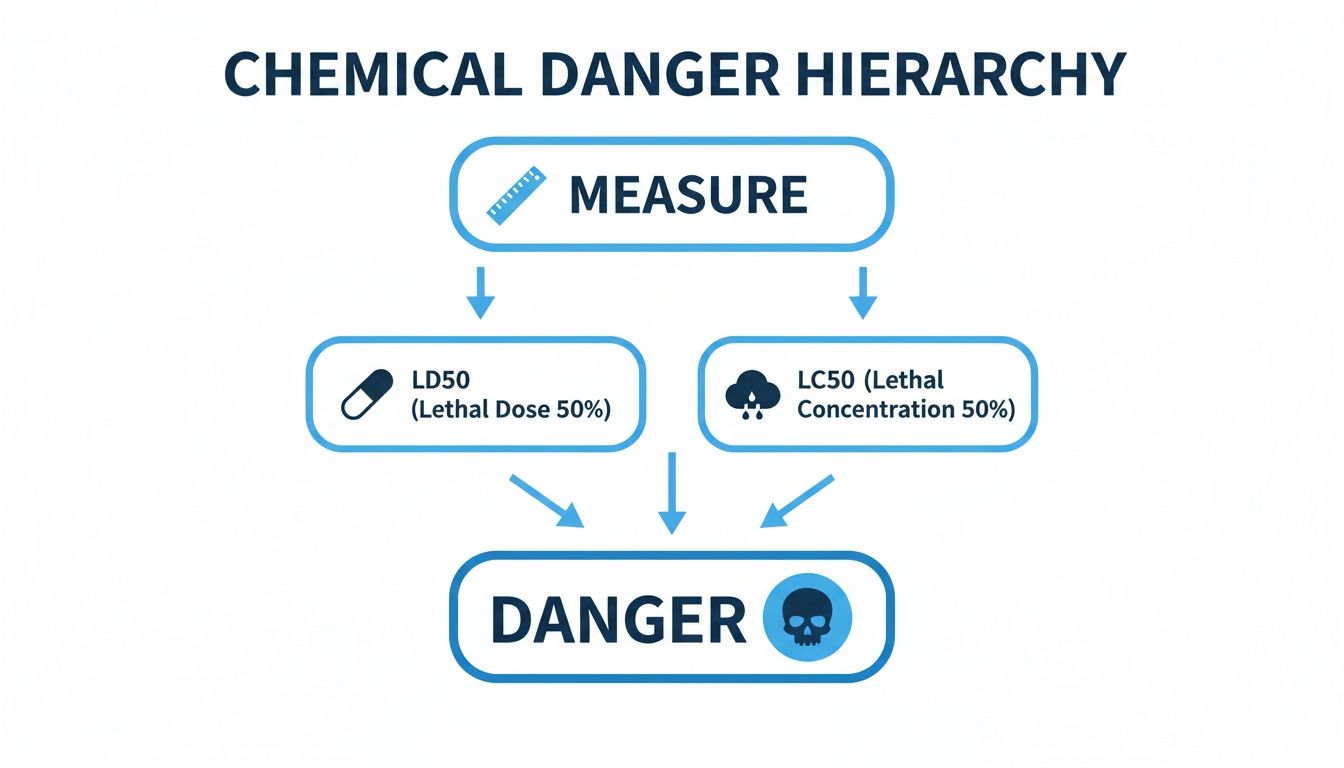

This flowchart shows exactly how those scientific measurements feed directly into the danger level you see on a label.

As you can see, the less of a substance it takes to be lethal, the higher up the danger scale it goes and the more serious the warnings become.

GHS Acute Toxicity Categories at a Glance

To make this crystal clear, here’s a quick-reference table breaking down the GHS categories for acute toxicity. It connects the hazard level to the specific signal words, pictograms, and LD50 values you'll encounter.

| Category | Hazard Level | Signal Word | GHS Pictogram | Example LD50 Range (Oral, rat) |

|---|---|---|---|---|

| 1 | Most Severe | Danger | Skull and Crossbones | ≤ 5 mg/kg |

| 2 | Severe | Danger | Skull and Crossbones | > 5 and ≤ 50 mg/kg |

| 3 | Serious | Danger | Skull and Crossbones | > 50 and ≤ 300 mg/kg |

| 4 | Moderate | Warning | Exclamation Mark | > 300 and ≤ 2000 mg/kg |

| 5 | Low | Warning | (None Required) | > 2000 and ≤ 5000 mg/kg |

This table is a powerful tool for quickly assessing the immediate danger posed by a chemical just by looking at its GHS classification.

Pictograms and Signal Words: The Visual Warning System

GHS doesn't stop at categories. It uses two powerful visual shortcuts to get the message across instantly: signal words and pictograms.

Signal words are your first clue to the severity of the hazard. There are only two:

- Danger: This is reserved for the most severe hazards, covering GHS Acute Toxicity Categories 1, 2, and 3. When you see "Danger," it means the substance poses a significant, immediate risk.

- Warning: This is used for less severe but still serious hazards, like those in Category 4. The risk is still there, but it’s not as acute as those marked with "Danger."

Working alongside the signal word is the pictogram—a bold symbol inside a red-bordered diamond that gives you a visual snapshot of the hazard. For a full rundown of all the symbols you might see in a workplace, this complete guide to laboratory hazard signs is an excellent resource.

When it comes to acute toxicity, there are two pictograms you absolutely need to know. The skull and crossbones is the universal sign for a severe, potentially fatal hazard (Categories 1-3). The exclamation mark is used for substances that are harmful but less severe (Category 4), often indicating risks like skin irritation or other non-lethal toxic effects.

Let’s tie it all together. A chemical with an oral LD50 of 40 mg/kg places it squarely in GHS Category 2. Its label must, by law, show the skull and crossbones pictogram and the signal word "Danger." It’s a clear, unmissable warning of its high acute toxicity. Learning to read these visual cues is one of the most important safety skills you can develop. To see how these elements fit into the bigger picture, check out our guide on all GHS labeling requirements.

Recognizing Acutely Toxic Substances on Site

It’s one thing to understand the theory behind LD50 values and GHS labels, but it’s another to connect those concepts to the actual chemicals sitting on your shelves. True workplace safety begins when you can spot these hazards in plain sight.

The real danger often hides in familiarity. Many acutely toxic substances are essential for industrial processes, making them common fixtures in facilities across countless sectors. When employees handle these chemicals day in and day out, a sense of complacency can creep in, masking the very immediate risks they pose.

Common Examples Across Industries

Let's ground this in reality. Many substances with high acute toxicity are probably in your facility right now, each with its own job to do and its own way of causing harm.

Here are a few common ones you're likely to encounter:

- Ammonia (Anhydrous): A workhorse in industrial refrigeration and agriculture, ammonia is a GHS Category 3 hazard. The primary risk is inhalation, which can cause severe respiratory burns and prove fatal at high concentrations.

- Chlorine: Essential for water treatment and disinfection, chlorine gas is extremely toxic. It’s a GHS Category 2 hazard for inhalation, capable of causing severe lung damage from even brief exposure.

- Hydrogen Sulfide: You might know it as "sewer gas." This chemical is a common byproduct in oil refining, wastewater treatment, and agriculture. As a GHS Category 2 hazard, it can cause immediate loss of consciousness and death through inhalation.

- Carbon Monoxide: This colorless, odorless gas is produced by any fuel-burning equipment, from forklifts to generators. It's a silent killer classified as a GHS Category 3 hazard that stops the blood from carrying oxygen, leading to rapid poisoning.

These are just a handful of examples, but they drive home the point: essential chemicals can also be incredibly dangerous. Knowing what they're used for and how you're most likely to be exposed is the first critical step toward controlling the risk.

Spotting Overlooked Chemical Hazards

While industrial gases tend to get the most attention, many other acutely toxic substances are hiding in plain sight, packaged as everyday cleaners, solvents, or lab reagents.

A core tenet of any good safety program is to challenge the assumption that "common" means "safe." Many industrial-strength cleaners contain chemicals like hydrofluoric acid or sodium hydroxide, both of which can cause immediate, severe tissue damage on contact. Always check the Safety Data Sheet (SDS), even for products that seem routine.

Even outside of industrial environments, acute poisoning is a major public health issue. Research shows that common substances are often the culprits. For instance, in 2023, ethanol and opioids were among the most frequently reported agents in poisonings, and the overall case fatality rate for documented exposures was 1.3%. You can explore the full public health findings to see just how prevalent these incidents are. This data serves as a stark reminder to be vigilant about all potentially toxic substances, not just the ones with obvious warning labels.

Building a culture of awareness means actively looking for these hidden dangers. When you train your team to recognize specific substances, read labels with a critical eye, and always consult the SDS, you empower them to see their workplace through a safety-first lens. It’s a proactive approach that turns a simple chemical inventory into a manageable set of known, controllable risks.

Protecting Your Team from Exposure

Simply knowing a chemical is dangerous isn’t enough. To keep people safe, you have to understand exactly how a substance can enter the body and cause harm.

Think of it like this: a substance that’s mostly harmless if it touches your work boots might be deadly if you breathe it in. The route of exposure is everything when it comes to risk, and controlling those entry points is the core of workplace safety.

The Three Routes of Chemical Exposure

Chemicals have three main ways of getting past our body's defenses. Each pathway presents a different kind of threat and requires its own set of precautions.

Inhalation (Breathing): This is the most common and often the most dangerous route on the job. When someone breathes in toxic vapors, mists, or dusts, those chemicals go straight into the lungs and are quickly absorbed into the bloodstream. This can cause damage throughout the entire body. A perfect example is inhaling solvent fumes in a confined space, which can rapidly cause dizziness, respiratory failure, or worse.

Dermal Absorption (Skin Contact): Don't underestimate the skin—it’s not a perfect shield. Direct contact allows certain chemicals to seep right through, causing anything from a localized chemical burn to systemic poisoning once the substance hits the bloodstream. An accidental splash of a pesticide can be just as hazardous as inhaling it.

Ingestion (Swallowing): While it sounds less likely, accidental ingestion is a very real risk. It usually happens when someone eats, drinks, or smokes without washing their contaminated hands first, transferring the chemical from a surface to their mouth.

The specific symptoms and their severity are directly tied to the route of exposure. That’s why you can’t have a one-size-fits-all approach to personal protective equipment for chemicals. You need respirators for inhalation hazards, but chemical-resistant gloves are the priority for dermal risks.

Recognizing Symptoms and Responding Effectively

The warning signs of acute toxic exposure can show up within minutes or hours, ranging from mild discomfort to a full-blown medical crisis. Spotting these symptoms immediately is critical.

Look out for common signs like:

- Dizziness, headaches, or confusion

- Nausea, vomiting, or stomach pain

- Skin irritation, rashes, or burns

- Coughing, wheezing, or shortness of breath

- Loss of coordination or consciousness

If you suspect an exposure has occurred, your first and most important move is to grab the Safety Data Sheet (SDS) and turn to Section 4 (First-Aid Measures). This section provides the specific, life-saving steps for that exact chemical.

This is no time for guesswork. The SDS is your emergency playbook. It tells you exactly what to do—and what not to do—for each route of exposure, like whether to induce vomiting or how to flush a chemical off the skin properly.

Following the SDS is non-negotiable. Your emergency plans should be built around these instructions. And remember, first aid is only one piece of the puzzle; having solid hazardous waste and chemical spill cleanup strategies is just as vital. Always make sure to give the SDS to any paramedics or emergency responders so they have the information they need to provide the right treatment.

Putting Acute Toxicity Data to Work in Your Safety Program

Understanding what acute toxicity is on paper is one thing. Turning that knowledge into a real-world, working safety system that actually protects your team is a completely different ballgame. It all starts with the humble Safety Data Sheet (SDS)—this is where the theory becomes practical, actionable intelligence.

To really get a grip on this, you have to know exactly where to look on an SDS. While it has 16 sections, you’ll want to zero in on two for acute toxicity information.

Section 2: Hazard Identification: Think of this as the executive summary. It’s where you'll find the official GHS classification (like "Acute Toxicity, Oral, Category 2"), the signal word (Danger or Warning), and the pictograms that give you an immediate visual cue, like the skull and crossbones.

Section 11: Toxicological Information: This is the nitty-gritty. It’s where you’ll find the hard numbers—the LD50 and LC50 values for different routes of exposure (oral, dermal, inhalation). This is the quantitative data that backs up the warnings you see in Section 2.

From Data on a Page to Proactive Safety Workflows

Once you get comfortable finding and making sense of this data, the next step is to weave it into your day-to-day operations. This is how you shift from a reactive safety posture—cleaning up messes—to a proactive one where you stop incidents before they even have a chance to happen.

A fantastic place to start is with procurement. Imagine being able to flag a highly toxic chemical before it's even ordered. By using acute toxicity data at this early stage, your EHS team can step in and ask the important questions: Is there a safer alternative we could use? If not, do we have the right engineering controls and PPE ready to go before that first container hits the loading dock?

When you screen chemicals at the purchasing stage, you turn your procurement team into your first line of defense. It’s a simple check that can prevent a world of risk from ever entering your facility, making compliance much easier down the road.

Let Technology Do the Heavy Lifting

Let’s be honest: manually digging through every single SDS to pull out toxicity data is not just tedious, it's a recipe for mistakes. This is where a modern, digital SDS management platform like NextSDS can be a game-changer. These systems don't just store documents; they turn them into dynamic safety intelligence.

For example, a good digital system can automatically pull out the LD50 and LC50 values as soon as an SDS is uploaded.

Instead of flipping through binders in a panic, a safety manager can see a chemical’s entire hazard profile, including its acute toxicity rating, with just a click. That kind of instant access is invaluable.

This automation creates a ripple effect across your entire program. The data pulled from the SDS can be used to:

- Enforce Your Rules: Automatically flag any chemical with high acute toxicity (think GHS Category 1 or 2) and instantly link it to your specific safe handling procedures or restricted storage areas.

- Simplify Risk Assessments: Give your EHS team the exact toxicological data they need to conduct thorough risk assessments, helping them prioritize controls for the most hazardous materials first.

- Supercharge Emergency Response: Imagine having first aid info from Section 4 instantly available on a phone or tablet just by scanning a QR code on a container. When seconds matter, that's how you get the right information to the right people, right away.

By building acute toxicity data directly into your workflows, you create a connected safety system. Critical information is always at your fingertips, compliance becomes simpler, and most importantly, your team is better protected.

Got Questions About Acute Toxicity? We've Got Answers.

When you're dealing with chemical safety, questions are a good thing. They mean you're thinking critically about protecting your team. Here are some straightforward answers to the questions we hear most often about acute toxicity.

What’s the Real Difference Between Acute and Chronic Toxicity?

It all comes down to time.

Acute toxicity is about the immediate or near-immediate harm that happens after a single, short-term exposure—anything less than 24 hours. Think of a sudden chemical splash causing a burn or inhaling a vapor that makes you dizzy right away. It's the "right here, right now" danger.

Chronic toxicity, on the other hand, is the slow burn. It’s the damage that builds up from repeated, lower-level exposures over months or even years. A classic example is lung disease developing from breathing in hazardous dust day after day.

So, in a nutshell: acute is the fast-acting punch, while chronic is the damage from a thousand tiny cuts over time.

How Do Scientists Figure Out a Chemical’s LD50 or LC50?

Historically, these crucial values were determined through tightly controlled toxicological studies using animal models. Today, however, the industry is making a significant shift toward alternative methods to reduce and replace animal testing, such as advanced computer modeling and sophisticated tests using cell cultures.

By law, manufacturers must report this data. You’ll always find the LD50 or LC50 values listed in Section 11 (Toxicological Information) of a product's Safety Data Sheet (SDS). This is the evidence that backs up its hazard classification.

If a Chemical Has a High LD50, Does That Mean It's Safe?

Not at all. This is a common and dangerous misconception.

A high LD50 value simply means a substance has low lethal acute toxicity. It takes a larger dose to be fatal. But that chemical could still be incredibly dangerous in other ways. For instance, it might be severely corrosive to skin, a known carcinogen, or cause long-term organ damage with repeated exposure.

Never judge a chemical's safety on a single data point. Always look at the full picture of hazards on the SDS and follow every single safety recommendation.

What’s the Very First Thing I Should Do in an Exposure Emergency?

Your absolute first priority is your own safety. Never rush into a dangerous situation.

Once you’re sure the area is safe to enter, get the exposed person away from the source of the chemical immediately.

Then, follow these steps without delay:

- Call for emergency medical help.

- Follow the specific first-aid instructions found in Section 4 of the product’s SDS.

- Have the SDS ready to give to the emergency responders when they arrive.

This simple process ensures the person gets the right, chemical-specific treatment as fast as possible.

Managing chemical safety data is complex, but the right tools can make it feel simple. NextSDS puts all your Safety Data Sheets in one place and automates hazard screening, giving your team immediate access to the critical info they need to prevent incidents and respond with confidence. Learn how NextSDS can strengthen your safety program.