At its core, chemical inventory management software is a dedicated digital system designed to track, manage, and report on every chemical within a facility. It's the modern answer to the risky, mistake-filled world of spreadsheets, giving your team a solid platform for safety, compliance, and day-to-day efficiency.

Moving Beyond Spreadsheets To Smart Chemical Management

Trying to manage hazardous chemicals with a spreadsheet is a lot like navigating a minefield with a blindfold. For too long, organizations have relied on this exact approach—cobbling together disconnected spreadsheets, dusty binders full of paper, and endless manual data entry.

This old-school method is just waiting for a disaster. Safety Data Sheets (SDS) disappear or go out of date. Expiration dates get missed. In the worst-case scenarios, dangerously incompatible chemicals end up stored side-by-side simply because no one had the right information to catch the mistake. It forces safety managers into a reactive loop, always stamping out fires instead of preventing them in the first place.

The Shift To A Central Control Tower

Chemical inventory management software is the air traffic control tower for your entire facility. It replaces that fragmented, manual chaos with a single, clear view of every chemical's lifecycle, from the moment it arrives at your dock to the day it’s safely disposed of. Think of it as a central nervous system, connecting your EHS teams, procurement department, and floor staff with accurate, real-time data.

This isn't just a minor upgrade; it’s a complete shift in how you approach safety. It gives you the power to:

- See Everything in Real-Time: Instantly know what chemicals are on-site, precisely where they are, and in what quantities.

- Automate Compliance: Effortlessly screen your inventory against global regulatory lists from OSHA, REACH, GHS, and more.

- Manage Risk Proactively: Spot potential hazards and conflicts before they turn into incidents.

- Free Up Your Team: Cut down on countless hours of administrative busywork, letting your experts focus on high-impact safety initiatives.

While chemical management has unique demands, the foundational ideas are universal. You can explore these core concepts in general inventory management best practices that apply to any industry.

The real power of chemical inventory management software is how it turns raw data into actionable intelligence. It transforms a simple list of chemicals into a dynamic tool for proactive safety and smart compliance.

Manual Spreadsheets vs Chemical Inventory Management Software

The difference between sticking with manual methods and adopting a dedicated software solution is stark. Spreadsheets, while familiar, simply can't keep up with the demands of modern chemical safety and compliance.

| Feature | Manual Tracking (Spreadsheets) | Chemical Inventory Management Software |

|---|---|---|

| SDS Management | Manual upload; easily outdated or lost. | Central, cloud-based SDS library; automated updates. |

| Regulatory Checks | Manual, time-consuming cross-referencing. | Automated screening against global regulatory lists. |

| Real-Time Data | Static; updated only when someone logs in. | Live, facility-wide visibility for all users. |

| Storage & Compatibility | Relies on human knowledge; high risk of error. | Automated incompatibility flagging and storage guidance. |

| Risk Assessment | Subjective, inconsistent, and often overlooked. | Standardized hazard scoring and risk reporting. |

| Reporting | Manual data compilation for regulatory reports. | One-click generation for Tier II, SARA, and others. |

In short, software provides a dynamic, intelligent system that actively works to keep you safe and compliant, whereas a spreadsheet is just a passive, static record of what you think you have.

The market is taking notice. The chemical software market was valued at USD 4.5 billion and is on track to hit USD 8.2 billion by 2033. This growth is fueled by industries realizing that manual methods are no longer viable in the face of complex regulations and supply chains. This isn't just about tracking bottles on a shelf—it's about building a stronger, data-driven safety culture from the ground up.

Core Features That Drive Modern Chemical Safety

Good chemical inventory software is so much more than a digital spreadsheet. Think of it as a dynamic safety engine, with a handful of core features that work in concert to shift your entire safety posture from reactive to proactive. Getting a handle on these pillars is the first step to unlocking a truly modern chemical management strategy.

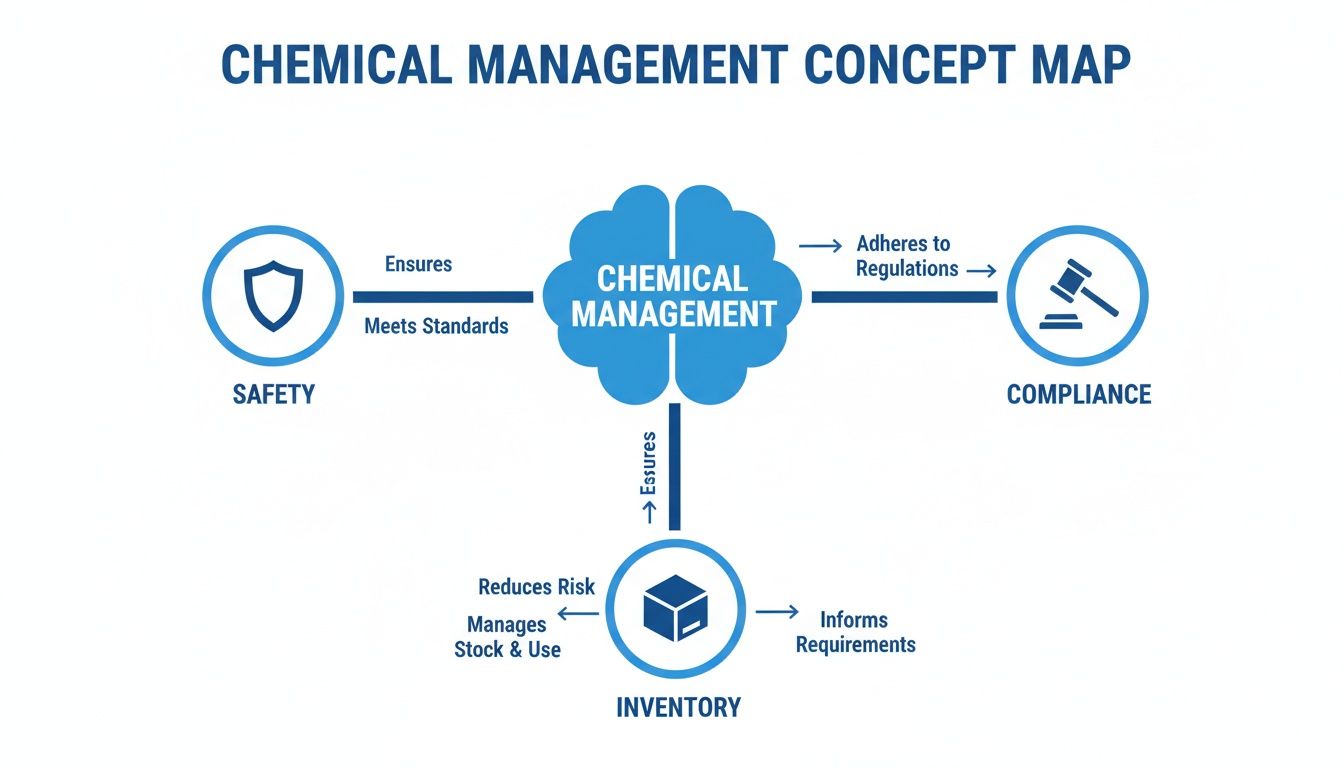

This is all about connecting the dots. Safety, compliance, and inventory aren't separate silos; they're deeply intertwined. The software acts as the central hub that brings them all together.

When these elements are connected, you move from just tracking chemicals to actively managing risk and ensuring compliance across the board.

Automated SDS Management

Let's be honest, managing Safety Data Sheets (SDS) manually is a nightmare. Binders disappear, files go out of date, and your team wastes precious time hunting down basic safety information during an emergency. Automated SDS management completely flips the script by creating a central, living digital library.

When a new chemical shows up at the loading dock, you're not sending an employee off to spend an hour manually keying in data. The software ingests the new SDS, using smart technology to pull out the critical details—CAS numbers, hazard warnings, PPE requirements—and makes it instantly searchable for everyone. This single feature is the bedrock of any reliable safety program.

Real-Time Regulatory Monitoring

The regulatory landscape is a constantly moving target. Keeping up with changes from local, federal, and global agencies is a full-time job in itself. This is where the software becomes your 24/7 compliance watchdog, continuously scanning your chemical inventory against countless regulatory lists.

This isn't about looking backward at what went wrong; it's about getting ahead of problems. The system will flag a chemical in your stockroom the moment it gets added to a restricted list like REACH or TSCA. That heads-up gives you the time to make informed decisions and sidestep costly violations before they ever happen.

A powerful chemical inventory management software doesn't just hold your data. It actively cross-references your inventory against thousands of regulations, turning a simple list into a live compliance dashboard.

This inventory management capability is a huge driver in the market. It makes up 20% of the entire chemical software space, valued at USD 207.96 million and projected to hit USD 314.77 million by 2031. That growth highlights just how essential it is for organizing and handling volatile substances safely.

Risk Assessment and Scoring

Not all chemicals are created equal. A gallon of bleach doesn't pose the same risk as a gallon of hydrofluoric acid. A key software feature is its ability to quantify that hazard, letting you focus your safety efforts where they'll have the biggest impact.

The system crunches the numbers—analyzing chemical properties, quantities, and storage locations—to generate a clear, objective risk score. This gives EHS managers hard data to identify high-risk areas, implement targeted safety controls, and justify a budget for new equipment. You stop guessing and start making strategic, data-driven decisions to protect your team.

Smart Storage Compatibility

Storing incompatible chemicals next to each other is one of the most dangerous—and preventable—accidents in a facility. Manually checking compatibility charts for every single substance is tedious and a recipe for human error.

Modern software automates this critical safety check. As soon as a chemical is logged into the inventory or assigned a shelf, the system instantly flags potential conflicts with anything stored nearby. It's a digital safety net that helps prevent dangerous reactions, fires, or toxic fumes from ever happening. The best tools are designed around real-world hazmat warehouse safety and compliance requirements.

On-Demand GHS Compliant Labeling

When it comes to OSHA and GHS, proper labeling isn't optional. Every single container, from a 55-gallon drum down to a tiny spray bottle, needs a clear and accurate label. Trying to create these by hand is slow, and it's easy for inconsistencies to creep in.

With an integrated labeling tool, you can print GHS-compliant labels whenever you need them. The software pulls all the necessary information directly from the SDS to ensure every label is perfect.

- Product Identifier: The chemical name and code.

- Signal Word: "Danger" or "Warning."

- Hazard Pictograms: The universal symbols that communicate risk at a glance.

- Precautionary Statements: Clear instructions for safe handling, storage, and first aid.

This ensures every container on your site speaks the same, clear language of safety. It's a fundamental part of any strong chemical inventory management program.

Automating Compliance in a Complex Regulatory World

Let's be honest: navigating the tangled web of global chemical regulations like OSHA, REACH, and GHS is a massive undertaking. For most EHS managers, it feels less like a task and more like a full-time job in itself. It's a high-stakes world where one small oversight can trigger steep fines, operational shutdowns, and, most importantly, put people at risk.

This constant pressure keeps teams in a reactive loop, always scrambling to catch up with the latest regulatory changes. Chemical inventory management software completely flips this script. Think of it as your tireless, automated compliance officer, constantly cross-checking your inventory against an incredibly complex and always-shifting legal landscape.

From Reactive Scrambles to Proactive Strategy

Imagine a procurement manager is about to order a new cleaning agent. Before they even click "approve" on the purchase order, the software screens the product's ingredients against a live database of restricted substances. It instantly flags that a key component is about to be added to a regional watchlist, automatically blocking the purchase and stopping a non-compliant chemical from ever setting foot in your facility.

This kind of proactive screening is a total game-changer. Instead of finding out you have a problem during a surprise audit, you prevent it from ever happening. The system turns compliance from a stressful, periodic fire drill into a quiet, continuous process running in the background.

This shift is crucial, especially since staying compliant is the number one reason companies adopt this technology. A recent survey found that 68% of EHS managers named compliance as their biggest challenge, and a staggering 45% reported audit failures because of outdated SDSs or untracked hazards. The right software transforms this nightmare scenario into a managed, predictable process by doing all the heavy lifting. You can learn more about these market drivers in this in-depth chemical software market report.

Audit Preparation in Minutes, Not Weeks

Remember the old way of preparing for an audit? It was a frantic scavenger hunt that pulled team members away from their real jobs for days, sometimes weeks. They’d be digging through binders, trying to make sense of conflicting spreadsheets, and just hoping every single Safety Data Sheet was present and up-to-date.

Now, picture the new workflow. An auditor calls. The EHS manager logs into the system. Within a few minutes, they can generate comprehensive, pinpoint-accurate reports detailing every hazardous substance on-site—its exact location, quantity, and all associated risks. Reports for SARA Title III, Tier II, or other local requirements are ready with just a few clicks. What used to take weeks of painstaking manual work is now done in less time than it takes to grab a cup of coffee.

This instant reporting is a core pillar of safety data sheet compliance, ensuring all your critical documentation is centralized and ready at a moment's notice.

The real win with automated compliance isn't just about passing audits. It’s about building a constant state of readiness. It frees your experts from tedious administrative work so they can focus on what they do best: making the workplace genuinely safer.

A Look Over the Horizon for Future Changes

The best chemical inventory software does more than just spot today's compliance gaps. It gives you a peek into the future with "horizon scanning," actively tracking proposed regulatory changes and upcoming deadlines from around the world.

This gives your team a critical heads-up, providing the time you need to adapt processes, find alternative materials, or update your safety protocols long before a new rule goes into effect.

Here’s how that plays out:

- Anticipate Restrictions: Get an alert months in advance when a chemical in your inventory is being considered for restriction under regulations like REACH.

- Plan for Phase-Outs: You can build a strategic plan to phase out certain substances before they become a major compliance headache.

- Stay Ahead of Labeling Updates: Prepare for changes to GHS or CLP labeling requirements well before the deadline arrives.

This kind of forward-looking intelligence is what separates basic compliance from true strategic risk management. You’re no longer just reacting to today's rules; you're actively preparing for tomorrow's regulatory environment. It’s a fundamental shift that builds a more resilient and confident safety culture across your entire organization.

Key Regulations Automated by Chemical Inventory Software

Keeping track of global regulations manually is nearly impossible. Different rules apply in different regions, each with unique reporting and documentation demands. Chemical inventory software centralizes these requirements, turning a complex global puzzle into a manageable, automated workflow. The table below shows just a few examples of how these systems tackle major regulations.

| Regulation (e.g., REACH, OSHA, GHS) | Core Requirement | How Software Automates Compliance |

|---|---|---|

| OSHA HazCom (USA) | Maintain an up-to-date SDS library and ensure GHS-compliant labels. | Automatically sources the latest SDS from manufacturers and generates compliant container labels with pictograms and hazard statements. |

| REACH (EU) | Register substances, track quantities, and manage Substances of Very High Concern (SVHCs). | Monitors inventory against the SVHC Candidate List, flags restricted chemicals, and helps generate reports on substance volumes. |

| GHS (Global) | Standardize hazard classification, labeling, and safety data sheets. | Provides a centralized, globally harmonized database for hazard information, ensuring consistency across all regions and products. |

| WHMIS (Canada) | Provide worker education and make bilingual (English/French) SDSs available. | Manages access to compliant SDSs in required languages and helps track employee training records related to specific chemical hazards. |

| SARA Title III (USA) | Report hazardous chemical inventories annually for emergency planning (Tier II). | Aggregates chemical quantity and location data to automatically generate accurate Tier II reports with just a few clicks. |

By translating these dense legal requirements into automated checks and balances, the software acts as a safety net. It ensures that no matter where you operate, your chemical management practices meet the required standard, protecting both your people and your business.

Calculating the Real ROI of Your Software Investment

While you can't put a price tag on safety, any major investment, including chemical inventory management software, ultimately has to answer one question: what's the return? The good news is that the ROI is often far more significant than most people realize, going way beyond just dodging fines.

A smart platform delivers a powerful financial payback by turning hidden operational waste into real savings. When you look at the ROI across three key areas, the business case becomes crystal clear. It’s about creating a leaner, smarter, and safer operation where every dollar works for you, not against you.

Uncovering Direct Cost Savings

The first and most obvious wins come from plugging the money leaks in how you buy and manage chemicals. Let's be honest, manual tracking with spreadsheets and clipboards is a recipe for waste, redundant orders, and hours of lost administrative time.

Think about how often different departments accidentally order the same chemical, leaving you with excess stock that expires on the shelf. It’s a common problem. In fact, some studies show that routine inventory management can eat up 25% of a scientist's time—a huge drain on your most skilled people.

This is where the software immediately pays for itself:

- Waste Reduction: By automatically tracking expiration dates, you can finally enforce a "first-in, first-out" (FIFO) system, drastically cutting losses from expired products.

- Optimized Purchasing: A single, shared view of your inventory stops duplicate orders in their tracks. You buy only what you actually need.

- Reduced Administrative Burden: Swapping manual data entry for automated tracking frees up countless hours for your EHS managers and lab staff to focus on more important work.

Strategic Risk Mitigation and Cost Avoidance

Beyond the immediate savings, the biggest financial impact often comes from what doesn't happen. A single non-compliance fine from an agency like OSHA or the EPA can easily cost tens of thousands of dollars. And the costs of a workplace accident—medical bills, legal fees, workers' comp—can be absolutely staggering.

The true financial power of chemical inventory software lies in its ability to prevent catastrophic costs before they occur. It's a proactive investment in financial stability, not just a reactive safety measure.

This is the essence of strategic cost avoidance. The software acts as a financial shield by keeping you compliant and improving your safety protocols day in and day out. It can even help lower your insurance premiums by proving your commitment to rigorous risk management. When an auditor shows up, you have an airtight record, turning a potential financial nightmare into a non-issue.

Boosting Operational Efficiency Across Teams

Finally, a well-chosen software solution pays you back by making your entire operation run better. How much time is wasted when a researcher has to hunt through three different cabinets for one chemical? Or when a production line grinds to a halt because a key reagent is out of stock? These "little" delays add up to a massive loss in productivity.

With modern chemical inventory management software, that friction just melts away. Anyone on your team can find a substance in seconds with a mobile device and a quick QR code scan. This puts critical information in the hands of the people who need it, from the lab bench to the loading dock.

Key efficiency gains include:

- Streamlined Workflows: New chemical requests can be routed through an automated approval process, ensuring they are vetted for compliance before you buy them.

- Instant Information Access: A QR code on a container can link directly to its SDS and safe handling info. No more flipping through binders or running back to a computer.

- Improved Team Productivity: When people can find what they need quickly and safely, projects move faster and your entire operation becomes more productive.

When you add it all up—the direct savings, the avoided costs, and the efficiency gains—the ROI on your software investment becomes undeniable. It’s a strategic move that pays dividends for your safety, your compliance, and your bottom line.

How to Choose the Right Software for Your Needs

Picking the right chemical inventory management software isn’t just about buying a product; it’s about finding a long-term partner in safety. With so many options out there, the process can feel overwhelming. But if you focus on a few key criteria, you can cut through the noise and find a solution that truly fits your organization.

The trick is to think in terms of practical questions. You're not just ticking boxes on a feature list. You’re looking for a system that solves real-world problems, from the warehouse floor all the way up to the compliance office. The right platform should feel like a natural extension of your team, making everyone’s job safer and a whole lot easier.

Scalability and Deployment Model

One of the first big decisions is figuring out how the software will be deployed and whether it can grow with your company. This choice affects everything from upfront costs to long-term maintenance and who can access it.

- Cloud-Based (SaaS): This is the "Software-as-a-Service" model, where the vendor hosts everything and you access it online. It usually means a subscription fee, lower initial costs, and you never have to worry about updates. This is a fantastic choice for most businesses that want flexibility without the IT headache.

- On-Premise: With this model, you install and run the software on your own servers. You get more control over your data, but it comes with a hefty initial investment in hardware and requires your IT team to manage it.

Don’t forget to ask vendors about scalability. Can the system handle a jump from 100 chemicals to 10,000 without slowing to a crawl? Your business will evolve, and your software needs to keep pace without forcing you to start from scratch.

Integration Capabilities

Your chemical management system can't live on an island. To really deliver value, it needs to talk to the other software you rely on, especially your Enterprise Resource Planning (ERP) platform.

Without solid integration, your new software is just another data silo. Real efficiency happens when your inventory, purchasing, and EHS data flow between systems, giving everyone a single, reliable source of information.

When you're evaluating a vendor, get specific with your integration questions:

- Do they have a well-documented API?

- Can it connect with our ERP system, like SAP, Oracle, or NetSuite?

- How does it sync with procurement to flag new chemical purchases for compliance review?

Getting this right eliminates tedious double-entry, slashes the risk of human error, and ensures your finance and EHS teams are always on the same page. To get a better handle on the nuts and bolts, it's worth exploring the core components of effective SDS management software.

User Experience and Vendor Expertise

Finally, never, ever underestimate the power of a clean, intuitive user experience (UX). The most feature-packed software on the planet is worthless if your team finds it too confusing to use. The interface has to be simple enough for an EHS manager pulling annual reports and for a warehouse employee scanning a container with their phone.

Pay close attention during a product demo:

- Is the main dashboard easy to understand at a glance?

- How many clicks does it take to pull up a Safety Data Sheet or find where a chemical is stored?

- Is the mobile app actually useful for tasks in the field?

Look beyond the software and size up the vendor. Are they just a tech company, or are they true safety and compliance experts? A real partner understands the fine print of regulations like GHS and REACH. They'll offer great training and have your back with responsive support when you run into trouble. You're not just buying lines of code; you're investing in expertise that will keep your people safe and your business compliant for years.

Your Step-By-Step Implementation Plan

Rolling out new chemical inventory management software isn't just an IT project. It's a fundamental shift in how your team handles safety and operations. A solid plan takes the guesswork out of the process, breaking down what feels like a massive undertaking into clear, manageable steps.

We’ve broken the whole thing down into four phases. Following this roadmap helps build momentum, gets your team on board, and lets you see the benefits of the new system much sooner.

Phase 1: Preparation and Data Gathering

Before you can import a single file, you need a crystal-clear picture of what you have right now. This first phase is all about getting your house in order and defining what you want to achieve.

Start by putting together your project team. You'll want people from EHS, procurement, and day-to-day operations at the table. Then, it's time for a full-scale audit of your chemical inventory and all the Safety Data Sheets (SDS) that go with it. This is also the perfect opportunity to clear out and safely dispose of any old or unneeded chemicals.

Setting clear objectives is a must. Define what success looks like. Is it cutting reporting time by 50%? Is it stopping duplicate chemical orders? Maybe it's acing your next compliance audit. These goals will be your North Star for the entire project.

Phase 2: System Configuration and Migration

With your data cleaned up and organized, you can start molding the software to fit your world. This is where you upload your tidy SDS library and inventory lists into the new system. It's smart to work closely with your software provider here to make sure every bit of data lands in the right place, accurately.

This is also when you'll set up custom workflows and decide who gets to do what. For example:

- Approval Chains: You can build automatic approval routes for new chemical requests, making sure EHS gives the green light before anything is purchased.

- Role-Based Access: Not everyone needs access to everything. You can define user roles so a lab tech can easily pull up an SDS, while only a manager can approve a high-volume order.

Phase 3: Team Training and Adoption

A great tool is useless if nobody knows how to use it. This phase is all about making sure everyone, from the lab to the loading dock, feels confident with the new software. Don't do one-size-fits-all training; customize sessions for different groups based on what they actually need to do their jobs.

Get people's hands on the keyboard (or the scanner). Show a lab tech how to scan a QR code on a bottle to get an SDS instantly on their phone. Walk a manager through generating a complex compliance report in just a few clicks. Real-world examples make it stick.

Phase 4: Ongoing Optimization

The work isn't over when you "go live." The final phase is really a continuous loop of getting better. Make it a point to ask your team for feedback. Where are the friction points? What could be easier?

Use the software's own analytics to keep an eye on important metrics like chemical usage patterns, waste, and upcoming expiration dates. This data is gold. It helps you tweak your procedures, cut down on waste even more, and continuously strengthen your safety culture long after the launch party.

Still Have Questions? Let's Clear a Few Things Up

It's natural to have a few questions when you're thinking about bringing a new system into your operations. We get it. Here are some of the most common things people ask when exploring chemical inventory management software.

How Does the Software Keep My SDSs Up to Date?

This is where the magic happens. Instead of you chasing down updates, the software does the heavy lifting. Many modern systems use smart tech to automatically scan your suppliers' websites for the latest versions. Some even give you a dedicated email address—just forward any update emails you get, and the platform ingests the new SDS, compares it to the old one, and flags any important changes for you. Your library stays current without you having to lift a finger.

Is This Kind of Software a Good Fit for a Small Business?

Absolutely. You don't have to be a massive corporation to reap the benefits. In fact, today's cloud-based systems are built to scale, making them incredibly affordable for small and medium-sized businesses. Since it's a subscription, you don't have to worry about a huge upfront investment in hardware. The reality is, automated compliance and better safety are just as crucial for a small lab as they are for a sprawling manufacturing plant.

The big takeaway here for smaller teams is that the right software levels the playing field. It gives you access to the same powerful safety and compliance tools the big guys use, but without the enterprise-level price tag.

Can the System Help Me with My Regulatory Reports?

Yes, and this is a huge time-saver. Generating reports for agencies like the EPA or OSHA is a core function of any good platform. With just a few clicks, you can pull together a detailed report listing all your hazardous substances, their exact quantities, and where they're stored. The system formats everything to meet the specific requirements for things like Tier II reporting, turning a multi-day headache into a five-minute task.

Ready to stop reacting to chemical safety issues and start proactively managing them? NextSDS gives you the automated tools you need to take control of your inventory, nail compliance, and keep your team safe. Discover how our all-in-one platform makes the complex simple by exploring our chemical management solutions.