When you're working with hazardous chemicals, the gear you wear is the last thing standing between you and a serious health risk. Personal protective equipment, or PPE, isn't just a box to check for compliance. It’s a carefully designed safety system that prevents everything from immediate injury to long-term illness caused by chemical exposure.

Understanding Your First Line of Defense Against Chemical Hazards

It's helpful to think of PPE for chemicals like a firefighter's turnout gear. You wouldn't send a firefighter into a blaze with a simple rain jacket. Their suit is a specialized system, with each piece engineered to combat specific dangers like intense heat and smoke. Your chemical PPE works the same way.

PPE is your most personal and final line of defense in a safety strategy called the hierarchy of controls. The top priority is always to remove a hazard entirely, but that's not always possible. When a dangerous chemical can't be substituted or engineered out of a process, PPE becomes absolutely essential.

This is a daily reality for countless professionals. For example, people in extermination and pest control services work with potent chemicals every day, making their PPE a non-negotiable part of the job.

Why PPE Is a System, Not Just Gear

Treating PPE as a complete system is a game-changer. It shifts your mindset from just "wearing the gear" to following a full-circle safety protocol where every piece works together.

A true PPE system involves:

- Hazard Assessment: Knowing exactly what chemical and physical risks you're up against for any given task.

- Correct Selection: Picking the right equipment that's actually rated to protect you from the specific chemicals you're handling.

- Proper Fit and Use: Making sure every piece, especially something like a respirator, fits perfectly and is worn correctly every single time.

- Maintenance and Inspection: Routinely checking your gear for wear and tear and knowing how to clean, store, or dispose of it properly.

This system-based approach is a cornerstone of building a robust safety culture. A truly effective chemical safety in the workplace program ensures every part of the process, from identifying the hazard to wearing the right gloves, is connected.

The best gear in the world is only as effective as the person wearing it. True protection comes from the combination of quality equipment, proper training, and the diligence to use it correctly every time.

Ultimately, we want to see PPE not as a chore, but as a life-saving toolkit. Every item you put on is a deliberate choice to shield yourself from a known danger. Grasping this concept is the first real step to mastering chemical safety and making sure your last line of defense is your strongest one.

How to Decode a Safety Data Sheet for PPE Selection

Think of a Safety Data Sheet (SDS) as a direct conversation with the chemical's manufacturer—it's their instruction manual for keeping you safe. It is, without a doubt, your single best source for figuring out exactly what personal protective equipment you need. Trying to choose PPE without it is like trying to assemble a car engine without the blueprint. You might get close, but the risk of a critical mistake is just too high.

These documents are packed with information, but when it comes to PPE, you’ll want to zero in on two key sections. By learning to read them together, you can build a complete picture of the protections you need. Before you dive in, it helps to understand the full scope of the document, and you can learn more about what a Safety Data Sheet is in our detailed guide.

Start with Section 8: Exposure Controls and Personal Protection

This section is ground zero. It’s the most direct and explicit part of the SDS for PPE guidance. Manufacturers are required to list their specific recommendations here to keep worker exposure to a minimum.

When you open up Section 8, you’re looking for a few key things:

- Eye/Face Protection: This will tell you if you need basic safety glasses with side shields, heavy-duty chemical splash goggles, or a full face shield. The guidance is directly tied to the risk of splashes, mists, or airborne particles.

- Skin Protection: Here, you'll find the requirements for your hands (gloves) and body (aprons, coveralls, or full chemical suits). Often, it gets very specific, recommending materials like nitrile, neoprene, or butyl rubber for gloves.

- Respiratory Protection: If the chemical releases harmful vapors, mists, or dust, this part will spell out the required breathing apparatus. It will clarify if a simple dust mask will do, or if you need a NIOSH-approved respirator with specific cartridges to filter out the hazard.

Section 8 gives you the "what," but to truly understand the "why"—and just how serious the risks are—you need to pair it with another crucial part of the SDS.

An SDS isn't just a compliance document; it's the manufacturer telling you, "Based on what this chemical can do, here is exactly how you must protect yourself."

Connect the Dots with Section 2: Hazards Identification

While Section 8 hands you a list of equipment, Section 2 explains why you need it. It lays out the chemical’s dangers in plain language, using standardized pictograms, signal words like "Danger" or "Warning," and clear hazard statements.

Think of it this way: Section 2 shows you a picture of a fire-breathing dragon (the hazard). Section 8 hands you the fireproof shield and tells you exactly how to use it (the PPE).

For example, if Section 2 shows the "Corrosion" pictogram and states, "Causes severe skin burns and eye damage," you know right away that Section 8 is going to call for some serious gear. You can expect to see requirements for chemical-resistant gloves, a face shield, and a protective apron or suit. The intensity of the hazard described in Section 2 directly maps to the level of protection specified in Section 8.

Putting It All Together: A Real-World Example

Let's say you're looking at the SDS for acetone, a common solvent.

Check Section 2: The first thing you'll see is the "flame" pictogram for flammability and the "exclamation mark" for irritation. The hazard statements will confirm it is a "Highly flammable liquid and vapor" and "Causes serious eye irritation."

Go to Section 8: Armed with that knowledge, the PPE recommendations become obvious. It will almost certainly call for splash-proof goggles to handle the eye irritation risk and solvent-resistant gloves (like butyl rubber or neoprene) to prevent any skin contact.

This simple two-step process—identifying the hazard, then finding the recommended controls—is the core of using an SDS to make smart PPE decisions.

Of course, manually sifting through hundreds of these documents is a huge time sink and leaves room for human error. That’s where modern platforms like NextSDS come in. They automate this whole process, instantly extracting PPE requirements from your entire SDS library. This ensures your team always has accurate, easy-to-find guidance right when they need it.

Choosing the Right Gear for Specific Chemical Threats

Picking out personal protective equipment for chemicals isn't like grabbing a jacket for the rain—one size most definitely does not fit all. Every chemical reacts with materials in its own unique way. This makes choosing the right PPE a critical balancing act between protection, durability, and the physical demands of the job.

You wouldn't use a paper umbrella in a hailstorm, right? It's the same idea here. A standard pair of latex gloves might be completely useless against a powerful solvent. The real skill is moving past generic gear and digging into the specifics of chemical compatibility, which is the absolute foundation of effective PPE selection.

Getting this right has become a massive focus across all industries. The global market for chemical protective clothing, valued at USD 1.49 billion just recently, is projected to skyrocket to USD 2.84 billion by 2033. This isn't just a trend; it's a response to stricter safety regulations. For instance, OSHA reported a 12% increase in citations related to hazardous chemicals in a single year, which puts serious pressure on employers to nail their PPE programs. You can explore the full research on chemical protective clothing market trends on Straits Research to see the data for yourself.

The Critical Concepts of Compatibility and Breakthrough Time

When you're choosing gear to protect against chemicals, two terms are absolutely non-negotiable: chemical compatibility and breakthrough time.

Chemical compatibility is just what it sounds like: how well a material can stand up to a specific chemical without degrading, dissolving, or getting weak. A manufacturer's chemical compatibility chart is your best friend for this, giving you a clear guide on which materials work for which substances.

Breakthrough time is even more specific. It's the measurement of how long it takes for a detectable amount of a chemical to seep through a protective material, like a glove or a suit. This isn't about when you see a hole or a tear; it’s about when the chemical starts migrating through on a microscopic level.

A glove that looks perfectly fine on the outside could already be allowing hazardous chemicals to reach your skin. Understanding breakthrough time means you know exactly how long your gear can safely protect you during a specific task.

This information, which you’ll find on the Safety Data Sheet (SDS) and in the manufacturer’s data, is crucial. It tells you whether a pair of gloves is safe for a quick five-minute job or if they need to be swapped out every hour to prevent exposure.

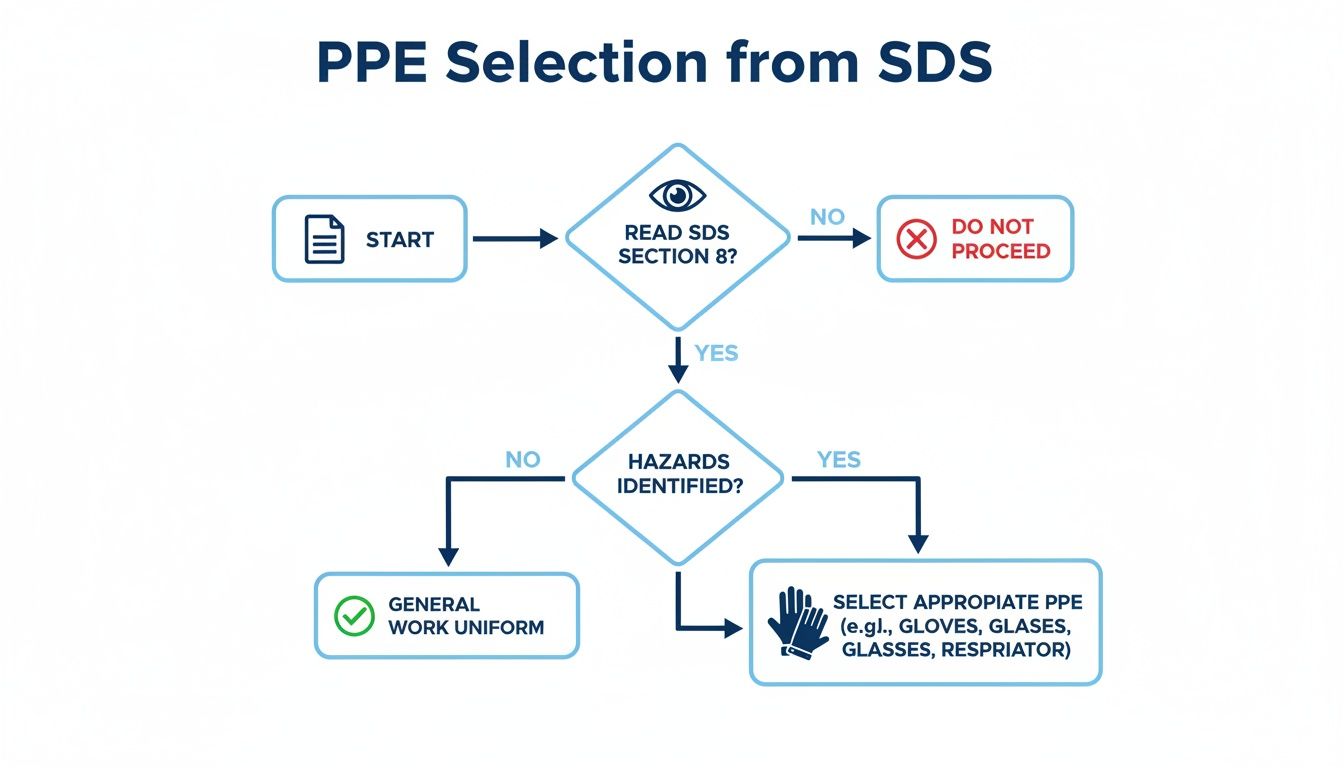

This flowchart gives you a simple visual for the first steps of using an SDS to guide your PPE selection.

As you can see, the process always starts with the SDS. You'll want to head straight to Section 8 to identify the specific PPE recommendations for the hazards you're dealing with.

Matching Materials to Chemical Threats

With those core concepts locked in, let's get practical and look at how to match common PPE materials to specific types of chemicals. The best choice often comes down to whether you're working with acids, bases, solvents, or something else entirely.

A solid understanding of different materials is key to making the right call. The table below breaks down some of the most common options for chemical protective clothing and where they excel—and where they fall short.

| Material Type | Best For (Chemical Class) | Not Recommended For | Common Applications |

|---|---|---|---|

| Nitrile | Oils, greases, many solvents, some acids | Ketones, strong oxidizing acids, aromatic solvents | General lab work, automotive, cleaning |

| Neoprene | Wide range of acids, caustics, oils, and alcohols | Aromatic and halogenated hydrocarbons | Chemical processing, manufacturing, refining |

| Butyl | Ketones, esters, aldehydes, strong acids/bases | Hydrocarbon oils, gasoline, aliphatic solvents | Hazmat response, highly corrosive chemical handling |

| PVC | Strong acids, bases, salts, some alcohols | Organic solvents, ketones, esters | Splash protection, electroplating, chemical transfer |

| Tyvek® | Dry particulates, light liquid aerosols/splashes | Significant chemical exposure, immersion | Asbestos abatement, painting, general maintenance |

Remember, this is just a starting point. Always, always double-check your specific chemical against the manufacturer’s compatibility chart before making a final decision.

A Closer Look at Gloves and Body Protection

Let's dive a bit deeper into the most common types of PPE you'll encounter.

For Your Hands: Choosing the Right Glove

- Nitrile: This is a fantastic all-rounder. Nitrile gloves provide excellent resistance to oils, greases, and a wide variety of solvents. They’ve become incredibly popular because they're also puncture-resistant and a great alternative for anyone with a latex allergy.

- Latex: Made from natural rubber, latex gloves are solid against bases, alcohols, and things mixed with water. Their big downside? They offer poor protection against petroleum-based solvents and are a well-known allergen.

- Butyl: This synthetic rubber is the gold standard when you're handling the really aggressive stuff, like ketones (think acetone) and esters. It also offers top-tier resistance to gases and water vapor getting through.

- Neoprene: Think of neoprene as a versatile workhorse. It holds up well against a broad spectrum of chemicals, including many acids, caustics, and some solvents, often outlasting nitrile against more aggressive substances.

For Your Body: Suits and Aprons

Just like with gloves, the material of your suit or apron is what stands between you and the hazard.

- Tyvek®: Made from high-density polyethylene fibers, Tyvek® is excellent for shielding against fine dry particles and very light liquid mists. It is not designed for significant chemical splashes or immersion.

- PVC (Polyvinyl Chloride): PVC is a cost-effective choice that gives you solid protection against a lot of acids, bases, and salts. You'll see it used frequently for splash aprons in chemical handling and industrial cleaning.

- CPE (Chlorinated Polyethylene): Known for being tough and resistant to a wide range of chemicals, CPE is often used for aprons and gowns where you need more robust protection from splashes.

Don't Forget the Task and the Chemical's State

Finally, your PPE choice has to make sense for the actual job you're doing and the form the chemical is in.

Chemical State: Is it a gas, liquid, or solid? A gas or vapor demands full respiratory protection and often a gas-tight suit. A liquid splash requires liquid-proof gear like goggles and a chemical-resistant apron. A solid powder might just need gloves and a dust mask to keep you from breathing it in.

Task Duration and Exposure: Are you just grabbing a quick sample, or are you in for an eight-hour maintenance marathon? The longer you expect to be exposed, the more critical the breakthrough time of your gloves and suit becomes.

Physical Demands: Does the job require fine motor skills? Heavy-duty butyl gloves offer incredible protection but can make you feel like you're wearing oven mitts. Lighter nitrile gloves might be a better fit if they offer sufficient chemical resistance for the task.

By pulling together information from the SDS, manufacturer compatibility charts, and a clear-eyed assessment of the task, you can move from guessing to knowing—and confidently choose the right PPE every single time.

Mastering Proper PPE Use: Donning and Doffing

Even the best chemical-resistant gear is worthless if you don't put it on and—more importantly—take it off correctly. Think of donning (putting on) and doffing (taking off) as your first and last lines of defense. A single misstep during removal can drag hazardous chemicals from the outside of your gear directly onto your skin.

This isn’t just about going through the motions; it’s a critical safety protocol. Rushing it or mixing up the order completely undermines the reason you're wearing PPE, turning your shield into a source of contamination.

The Correct Sequence for Donning PPE

Putting on your gear in the right order is all about creating a secure, overlapping seal that leaves no entry points for chemicals. The basic idea is to work from the inside out, building your core protection before adding the final outer layers.

Here's a standard donning sequence you'd use when handling liquid chemicals:

- Inner Gloves: Start by putting on your first pair of gloves. This gives you a clean base layer to work with.

- Chemical Suit or Coveralls: Step into the suit, making sure it doesn’t drag on a potentially contaminated floor. Zip it up all the way.

- Respirator: If a respirator is required, now's the time. Put it on and perform a seal check to ensure it’s fitted properly.

- Goggles or Face Shield: Place your eye protection over the respirator straps. This helps create a snug fit against your face.

- Outer Gloves: The final step is your second pair of chemical-resistant gloves. This is crucial: the cuffs of these outer gloves must go over the sleeves of your suit. This simple overlap prevents chemicals from running down your arms and getting inside.

Before you even think about entering the work zone, have a coworker or safety supervisor give you a once-over. A quick buddy check can spot gaps or tears you might have missed.

Why the Doffing Process Is So Critical

This is it—the moment of highest risk. After a job, every square inch of your PPE is potentially contaminated. The entire point of the doffing procedure is to get all that gear off without letting the "dirty" exterior touch the "clean" inside—your skin and clothes.

The most common cause of exposure when using PPE isn't equipment failure; it's improper removal. The doffing sequence is your final, and most important, act of self-protection.

The mindset here is simple: assume everything on the outside is hazardous. You'll want to touch as little of the exterior as possible, usually by rolling the equipment away from your body as you go.

A Step-by-Step Guide to Safe Doffing

The doffing sequence is basically the reverse of donning, and for good reason. It’s designed to get the most contaminated items off and away from you first.

- Decontaminate Outer Gear: If your site procedures call for it, this is when you’d rinse or wipe down your suit and outer gloves before you start taking anything off.

- Remove Outer Gloves: This step needs your full attention. Pinch the outside of one glove at the wrist with your other gloved hand. Peel it off, turning it inside out as you go. Ball up that removed glove into your still-gloved hand. Now, slide two fingers from your bare hand inside the cuff of the remaining glove and peel it off from the inside, trapping the first glove inside the second.

- Remove Goggles or Face Shield: Grab them by the straps at the back of your head and pull them forward, away from your face. Don't touch the front.

- Remove Chemical Suit: Unzip the suit completely. Peel it downward and away from your body, rolling it inside out as you step out of it.

- Remove Respirator: Unhook the straps from the back of your head and pull the respirator away from your face.

- Remove Inner Gloves: Use that same glove-in-glove technique you used for the outer pair.

- Wash Hands: Don't skip this. Immediately wash your hands and face thoroughly with soap and water.

Following this meticulous process ensures you contain the hazards and walk away clean. Remember, consistent training and practicing these steps are just as important as the quality of the chemical PPE you choose.

Integrating PPE into a Modern Safety Program

Having the right gear is just the beginning. Real chemical safety—the kind that truly protects your people—comes from weaving PPE management into a smarter, more comprehensive safety program. It’s about moving beyond simply handing out gloves and goggles. This shift transforms PPE from a reactive chore into a proactive, data-informed strategy.

The whole thing rests on a few core pillars that every employer is responsible for. It starts with a solid hazard assessment to actually understand the risks, gets codified in a formal written program, and stays alive through consistent, effective employee training.

Building a Formal Written PPE Program

Think of a written PPE program as your company’s single source of truth for chemical protection. It’s the playbook that ensures everyone, from the loading dock to the lab, is on the same page and following the same safety standards. This document isn't just a bureaucratic hoop to jump through; it's a vital operational tool.

A truly effective program needs to clearly spell out a few key things:

- Hazard Identification: How you will conduct and document workplace hazard assessments for every single task that involves chemicals.

- PPE Selection Criteria: The exact PPE required for each task, making sure it’s directly tied to the hazards spelled out in the Safety Data Sheet (SDS).

- Training Protocols: What gets covered in training, how often it happens, and the specifics of proper use, limitations, care, and disposal for all required gear.

- Recordkeeping: A solid system for tracking everything from training sessions and fit tests to equipment inspections.

When you have this kind of structure, you eliminate the guesswork. Safety protocols become consistent and reliable across the entire operation, creating a standard you can count on.

The Power of Data in Modern PPE Management

Not too long ago, managing PPE was a painfully manual job. Safety managers would burn hours digging through dusty binders of SDSs, cross-referencing chemical lists, and trying to keep track of who was trained on what. Thankfully, technology has completely changed the game.

Modern Environmental, Health, and Safety (EHS) platforms essentially act as the central nervous system for your entire safety program. By digitizing and analyzing your SDS library, these systems can automate critical tasks that used to be riddled with the potential for human error. They finally connect the dots between the chemicals on your shelves and the people who handle them.

By bringing technology into the mix, you’re fundamentally changing your posture from reactive to proactive. The system can flag compliance gaps, pinpoint high-risk areas, and give you the hard data to make smarter safety decisions before an incident ever happens.

This data-driven approach offers a level of insight that was almost unimaginable before. Imagine being able to instantly pull a list of every employee who needs a respirator fit-test for a new solvent that just arrived. Or getting an automatic alert when someone’s training certification is about to expire.

Streamlining Compliance and Training with Technology

One of the biggest wins from integrating technology is how it streamlines workflows and keeps you compliant. The right platform can automatically pull PPE requirements directly from Section 8 of every single SDS in your library, creating one central, searchable database.

This means that instead of a worker having to hunt down a physical binder in an office somewhere, they can pull up specific guidance right on a phone or tablet at their workstation. This immediate access to information is absolutely crucial for making sure the right personal protective equipment for chemicals gets used every single time.

Here are a few powerful ways this technology can support your safety program:

- Automated PPE Generation: Instantly creates accurate PPE requirement lists for any chemical in your inventory, pulled directly from the manufacturer's SDS.

- Compliance Gap Analysis: Constantly scans your chemical inventory against regulatory lists, alerting you to restricted substances and helping ensure your PPE standards are always current.

- Simplified Training Management: Tracks every employee’s training records, sends out automatic reminders for refreshers, and provides digital access to training materials.

- Enhanced Risk Assessments: Delivers the data you need to perform more accurate risk assessments by connecting specific chemicals to the tasks and workers who face potential exposure.

This level of automation turns your SDS library from a passive compliance document into an active safety tool. For anyone looking to make this leap, the first step is understanding what modern platforms can do. You can learn much more about how to centralize your chemical data by exploring the benefits of dedicated SDS management software in our comprehensive guide. When you connect your chemical data directly to worker protection, you're building a smarter, safer, and more efficient workplace.

Common Questions About Chemical Protective Equipment

When it comes to chemical safety, even with a solid grasp of the basics, the devil is always in the details. The questions that pop up on the job site are rarely textbook examples. This section tackles some of the most common, real-world questions we hear about chemical PPE, offering straight answers to help you make smarter, safer choices.

Think of this as your practical troubleshooting guide. A good mechanic knows more than just how an engine works—they know what that weird clanking noise means. In the same way, understanding the nuances of your gear is what prepares you for the challenges you'll actually face.

How Often Should Chemical Protective Gloves Be Replaced?

This is a big one, and the answer is never as simple as "every Friday." The right replacement schedule depends entirely on the situation, and getting it right is a cornerstone of any effective PPE program.

Several factors tell you when a glove has reached the end of its safe life:

- Breakthrough Time: We've talked about this, but it's worth repeating. This is the clock ticking down the moment a chemical touches the glove. For aggressive chemicals, breakthrough can happen in minutes, which makes the gloves strictly single-use for that task.

- Manufacturer Guidelines: Don't guess. The manufacturer’s data sheets are your best friend here, providing specific performance data against a list of chemicals.

- Visual Inspection: Before every single use, give the gloves a once-over. Look for discoloration, swelling, cracking, stiffness, or tiny punctures. If you see any sign of damage, it's done. Dispose of it immediately.

- Exposure Type and Duration: A glove that gets a quick, accidental splash is a world away from one that's fully immersed in a chemical for an hour. The intensity of the work matters.

A truly robust safety program doesn't leave this to chance. It establishes clear replacement schedules based on a risk assessment for each specific job, taking the guesswork out of the equation so your team is never left exposed.

Does Wearing Two Pairs of Gloves Offer More Protection?

Yes, double-gloving can be a highly effective tactic for handling especially nasty chemicals, but there’s a right way to do it. It’s not just about adding a layer; it’s a strategic move to build in a margin of safety.

The main advantage is having a clean backup. If the outer glove gets torn or contaminated, the inner glove is still pristine, protecting your skin while you safely peel off the compromised outer layer.

Think of it like a diver's backup air tank. You hope you never need it, but it’s a critical safety buffer that lets you get out of a dangerous situation without a catastrophe.

Often, the best approach involves using two different types of gloves. For example, a thin, flexible nitrile glove underneath a heavy-duty butyl glove can provide broader chemical resistance while still allowing for decent dexterity. The key is making sure the outer glove's cuff is pulled securely over the sleeve of your suit to prevent anything from dripping inside. Because it can reduce your sense of touch, this practice should only be used after a thorough, task-specific risk assessment.

What Is the Difference Between a Respirator and a Surgical Mask?

This is a common and incredibly dangerous point of confusion. Respirators and surgical masks are built for completely different jobs and offer wildly different levels of protection.

A surgical mask is designed to protect other people from the person wearing it. It’s a simple barrier that stops large droplets from the wearer’s mouth and nose from contaminating a sterile field or a patient. It offers the person wearing it almost zero protection from inhaling chemical vapors, gases, or fine airborne particles. It is not chemical PPE.

A respirator, on the other hand, is engineered specifically to protect the wearer. It creates a tight seal against the face and filters contaminants out of the air you breathe. When dealing with chemical exposure, you must use a NIOSH-approved respirator with the correct chemical cartridges for the specific hazard you're up against. And critically, anyone required to wear a tight-fitting respirator must first be medically cleared and properly fit-tested to ensure that seal is airtight.

Who Is Responsible for Paying for PPE in the Workplace?

The law is very clear on this. Under regulations from bodies like the Occupational Safety and Health Administration (OSHA) in the United States, the employer is legally required to provide and pay for all necessary PPE.

This isn’t just a suggestion; it’s a mandate. The requirement covers all the gear needed to keep employees safe from workplace hazards, including:

- Chemical-resistant gloves

- NIOSH-approved respirators

- Chemical suits and aprons

- Safety goggles and face shields

The employer's duty doesn't stop after the first purchase, either. They are also on the hook for replacing worn or damaged PPE and must ensure every employee gets solid training on how to use their gear correctly, understand its limitations, and maintain and dispose of it properly.

Juggling all these details—from digging through SDSs for PPE requirements to tracking training and compliance—can feel like a full-time job in itself. That’s why modern EHS teams rely on NextSDS. Our platform automatically pulls PPE requirements from your SDS library, keeps an eye on regulatory changes for you, and gives your team instant mobile access to the safety info they need, when they need it. Stop the guesswork and build a smarter, more proactive safety program by visiting https://nextsds.com.